Reinforcing structure and method for assembled continuous box girders

A reinforced structure and assembled technology, which is applied in the direction of bridge reinforcement, erection/assembly of bridges, bridges, etc., can solve the problems of poor overall stiffness, large disturbance of the original beam, and low construction efficiency, so as to achieve the improvement of overall section stiffness and single beam stress The effect of improving the state and improving the overall mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

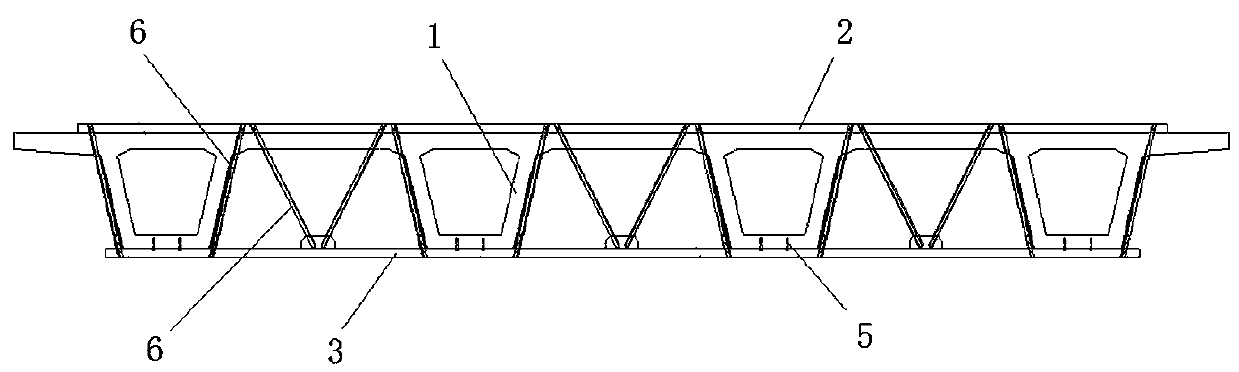

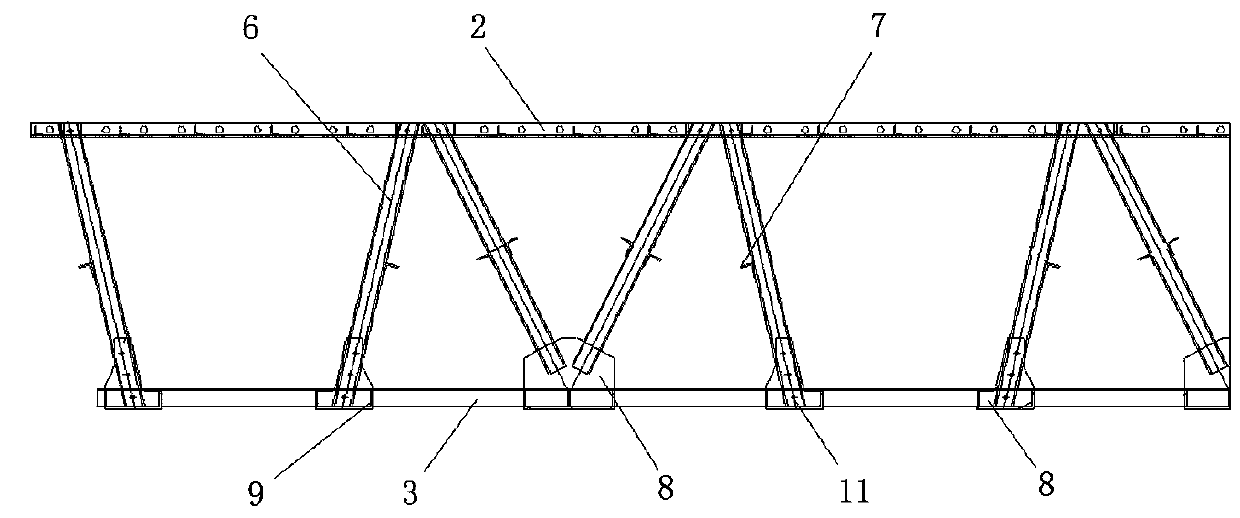

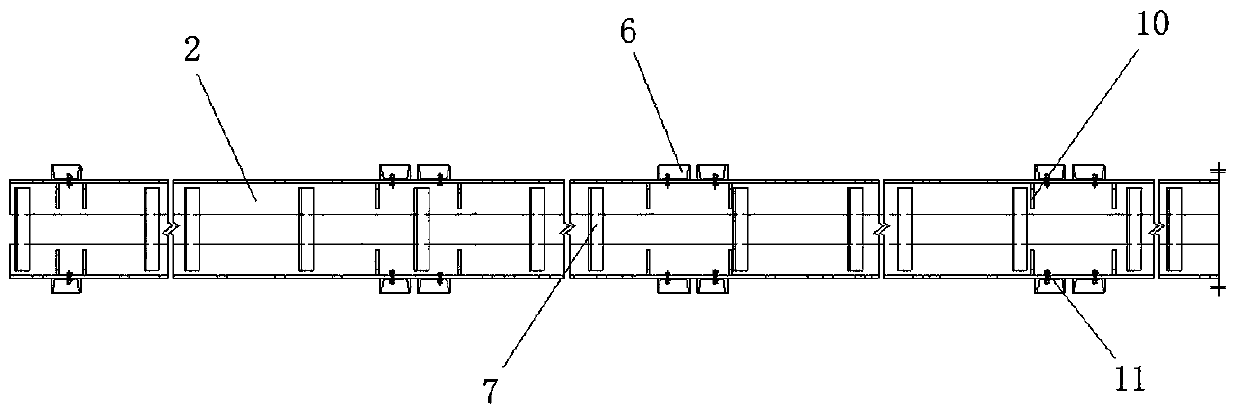

[0020] An assembled continuous box girder reinforcement structure is composed of a steel truss arranged on the box girder 1. The steel truss includes two upper chords 2 arranged on the flange of the box girder 1 and distributed front and rear and located on the box girder 1. The channel steel-shaped lower chord 3 at the lower end surface of the bottom, the channel steel-shaped lower chord 3 is provided with a number of anchor bolt holes 4, and the anchor bolt 5 connected with the bottom of the box girder 1 is arranged in the anchor bolt hole 4, two upper chords 2 There are webs 6 passing through the box girder 1 and located between the web of box girder 1 and adjacent box rooms between the outer side of the channel steel-like bottom chord 3 and the front and rear sides of the channel steel-shaped bottom chord 3, and the webs of the box girder 1 web The webs 6 are fixed to the web of the box girder 1, and the middle parts of each pair of front and rear corresponding webs 6 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com