Wind power mixing tower barrel based on edge stiffening combined shell

A hybrid tower and edge technology, applied in wind power generation, tower, installation/support configuration of wind turbines, etc., can solve the problems of large diameter and wall thickness of the tower, difficult construction, waste of materials, etc., and achieve high production efficiency and construction. Convenient, reliable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

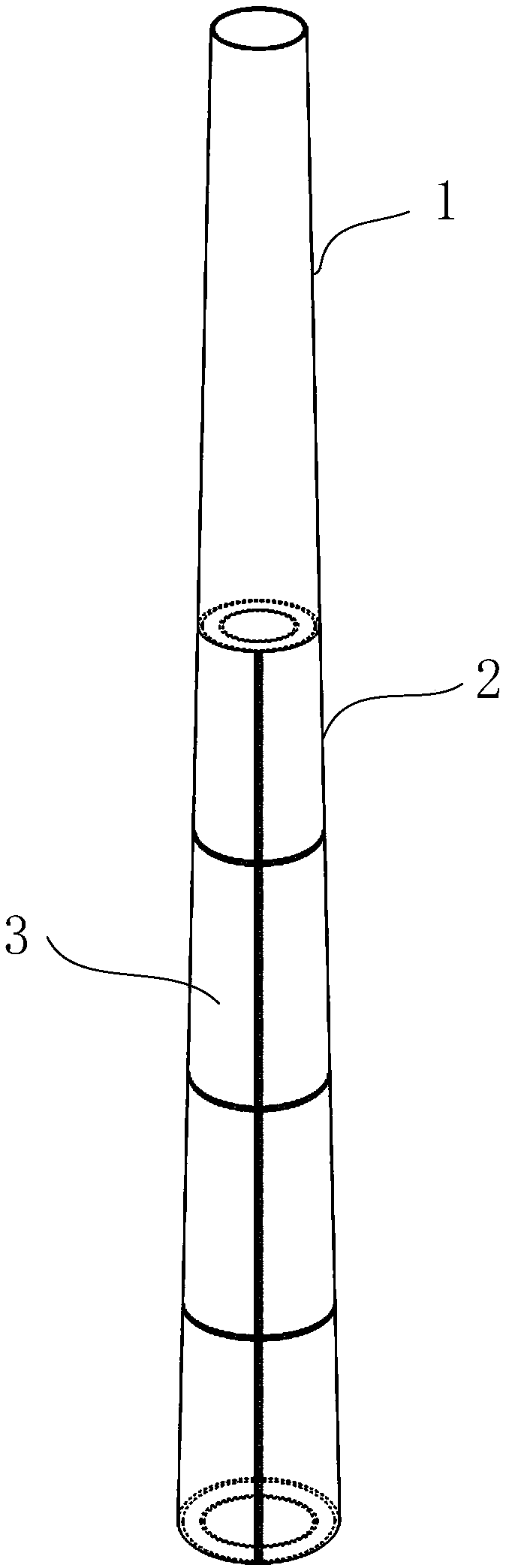

[0022] Such as figure 1 As shown, a wind power hybrid tower based on an edge-stiffened composite shell, the upper part of the system is a pure steel tower (1), and the lower part is a composite tower (2). The combined tower (2) is assembled from multiple edge-stiffened combined shells (3).

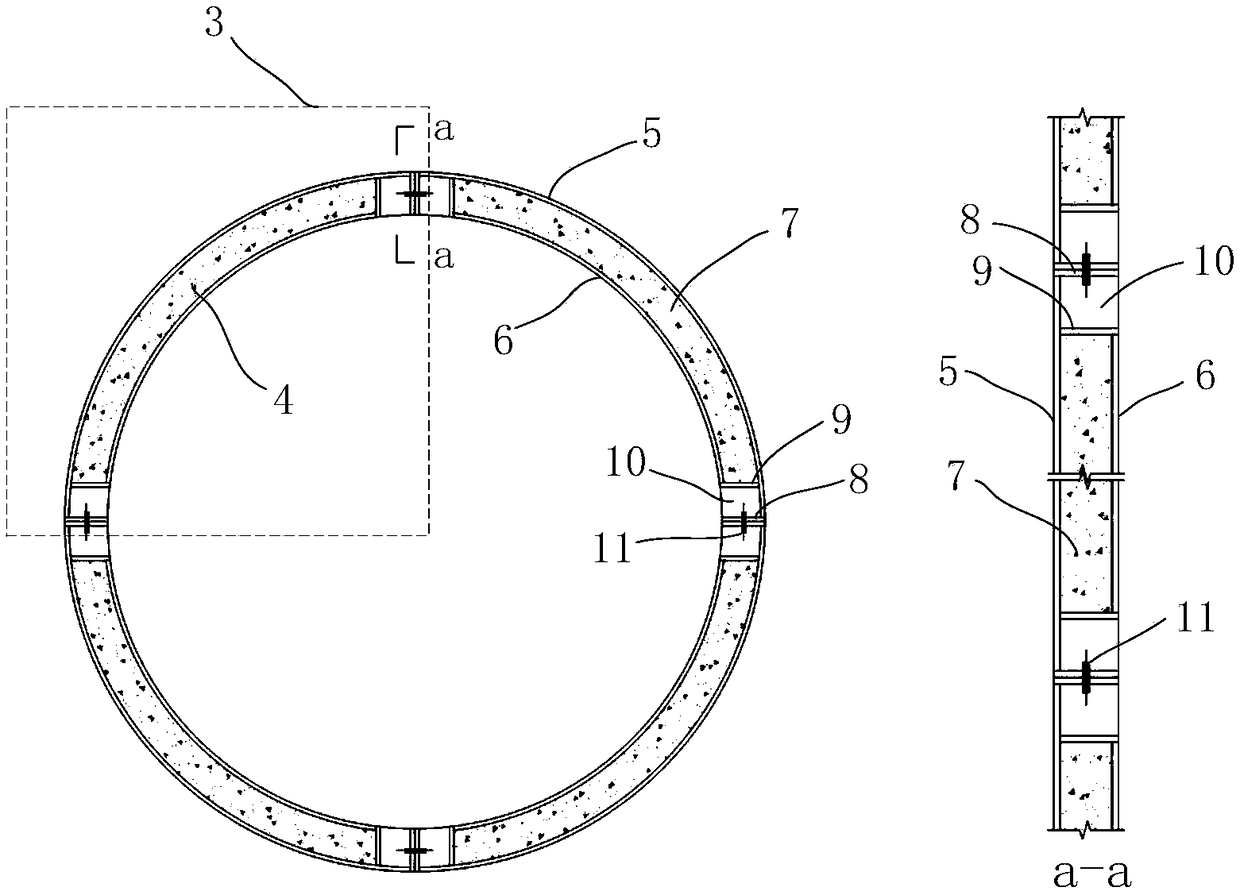

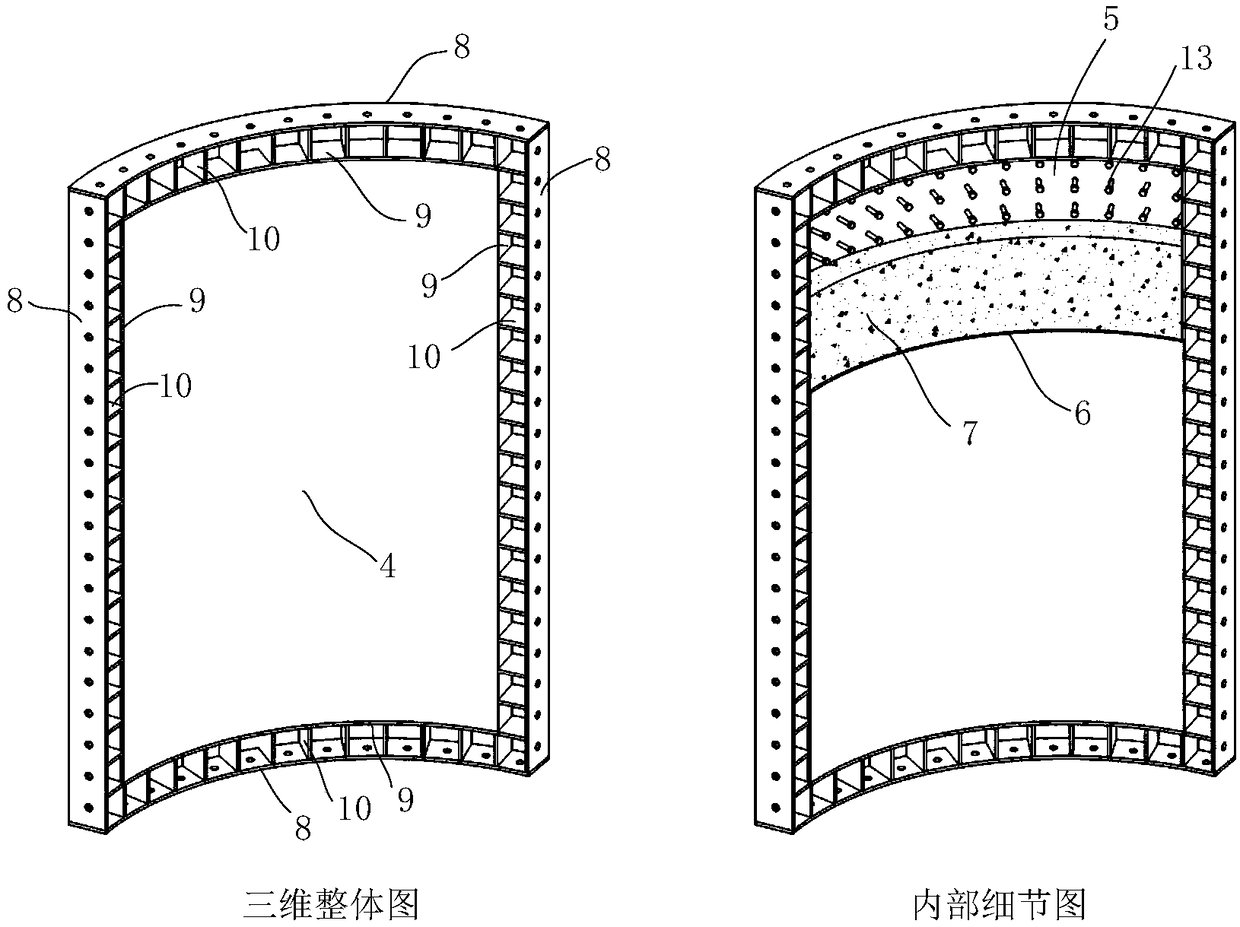

[0023] Such as figure 2 As shown, the combined tower (2) is assembled from 2 to 8 pieces (4 pieces are taken as an example in the figure) edge-stiffened composite shells (3) along the ring direction, and assembled in sections along the vertical direction; the edge-stiffened composite shells The body (3) is prefabricated in the factory and is composed of hollow interlayer concrete filled steel pipe (4) and outer end plates (8), inner end plates (9) and stiffening plates (10) arranged around it; adjacent edge stiffening composite shells (3) are connected by bolts (11).

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com