Totally-assembled type hollow interlayer steel pipe concrete combined tower barrel and joints

A steel tube concrete and full assembly technology, which is applied in the installation/supporting configuration of wind turbines, wind turbines, engines, etc., can solve the problems of large diameter and wall thickness of the tower, waste of materials, and difficulty in construction, so as to save material consumption, The effect of convenient construction and low material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

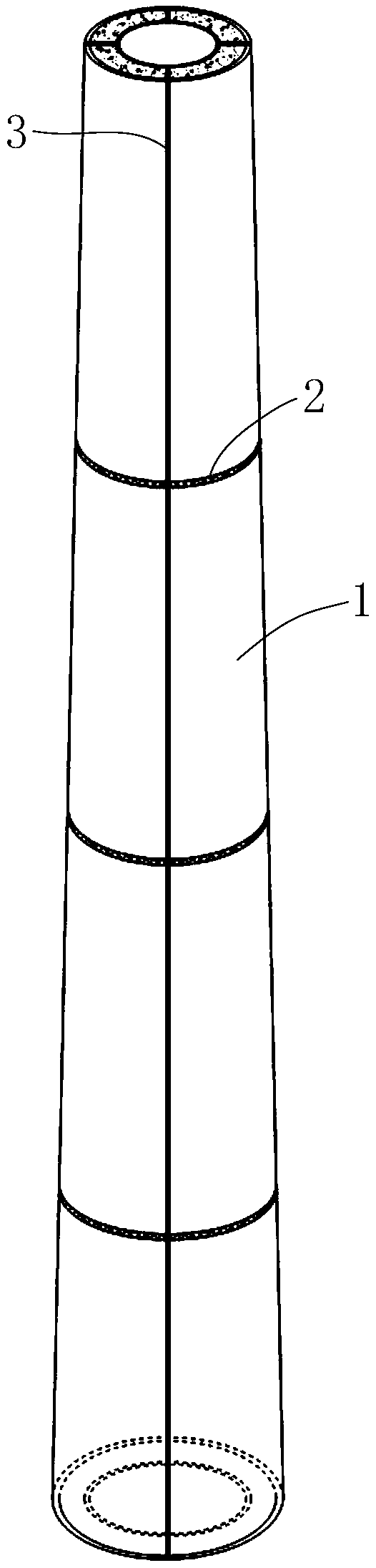

[0025] Such as figure 1 As shown, a fully assembled hollow interlayer concrete-filled steel tube composite tower and nodes, the system is mainly composed of hollow interlayer concrete-filled steel tube tube body (1), transverse nodes (2), and longitudinal nodes (3). The hollow interlayer concrete-filled steel tube body (1) is divided into 2 to 8 pieces along the circumferential direction, and adjacent pieces are assembled and connected by transverse nodes (2); the hollow interlayer concrete-filled steel tube body (1) is assembled in sections along the height direction, and the They are connected by vertical nodes (3).

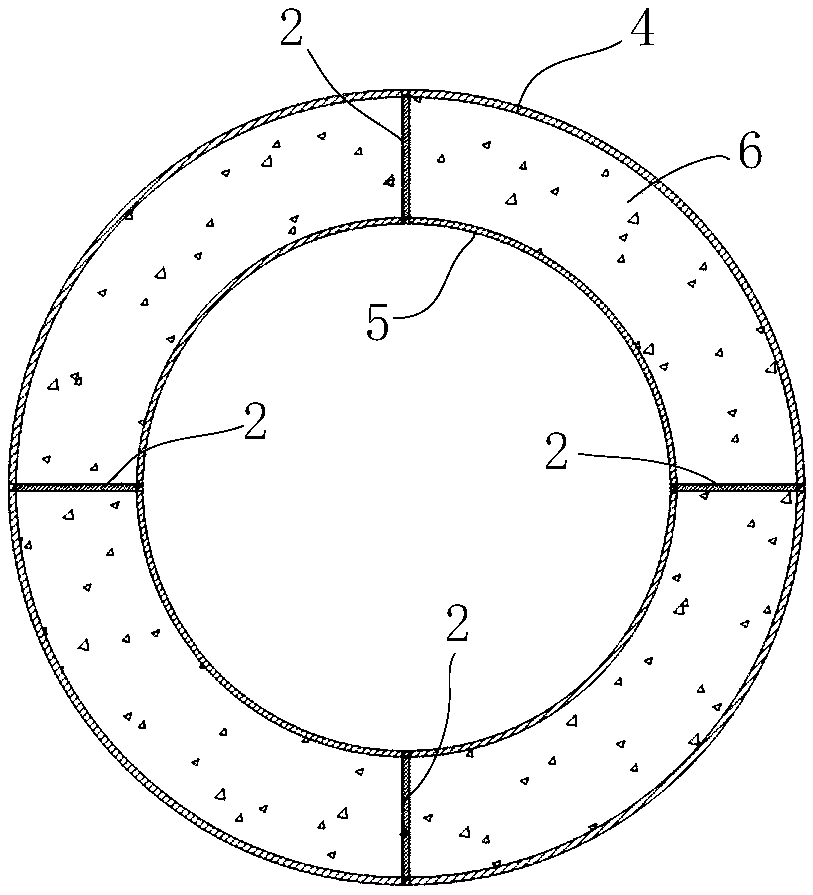

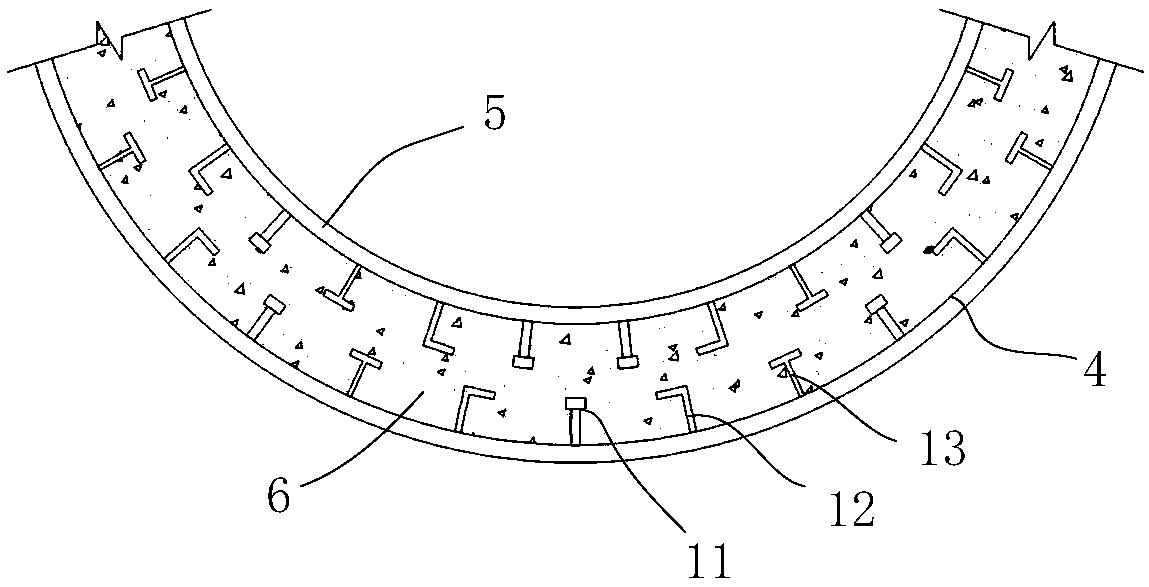

[0026] Such as figure 2 As shown, the hollow interlayer concrete tube body (1) is composed of an outer steel tube (4), an inner steel tube (5) and concrete (6). The cross-sections of the outer steel pipe (4) and the inner steel pipe (5) gradually be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com