Copper base-graphite positive gradient composite and preparation method thereof

A technology of composite materials and graphite, applied in heat exchange equipment, stators, transmission devices, etc., can solve the problems of powder density, particle size gradient change requirements, low density, complex process, etc. Insufficient strength, guaranteed self-lubricating performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

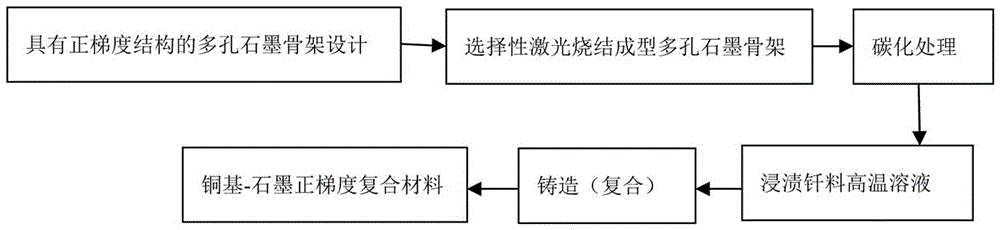

[0023] Concrete preparation steps are as follows:

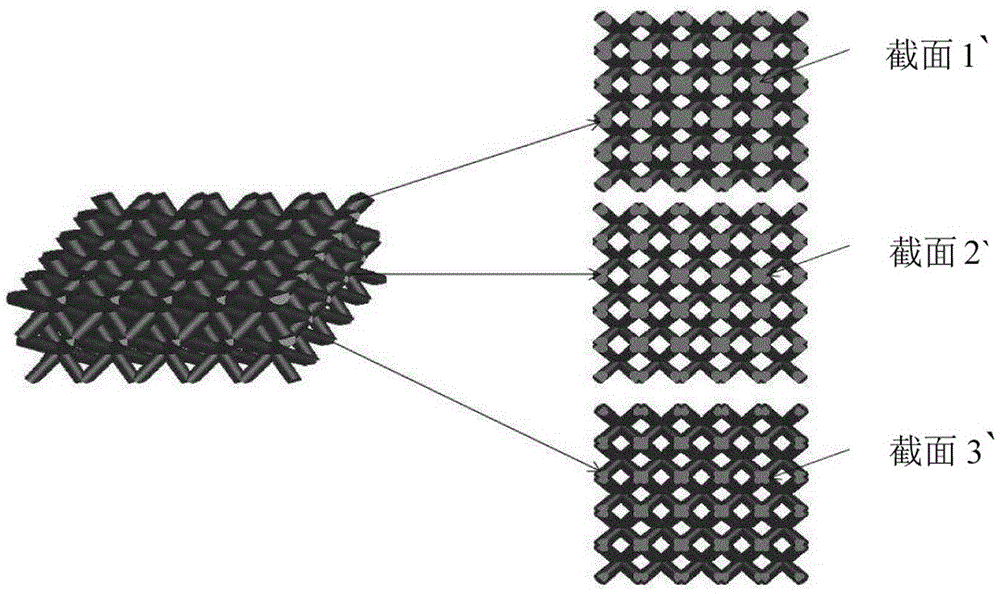

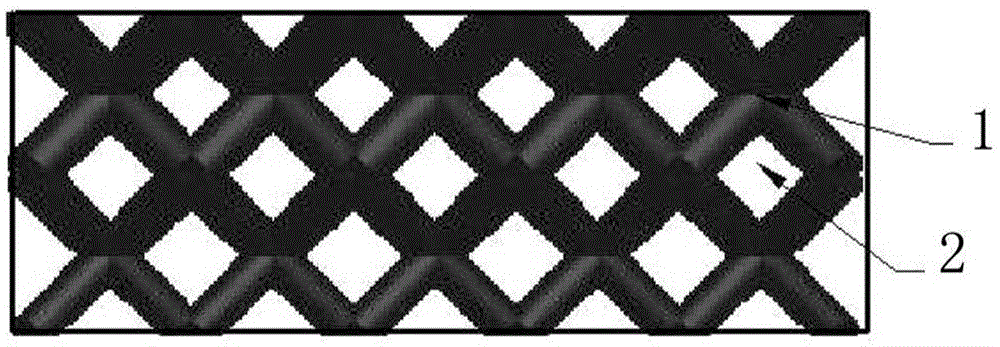

[0024] Step 1: Take graphite powder (200 mesh, purity 99.5%) and phenolic resin powder (600 mesh), mix them evenly and put them into a selective laser sintering molding machine, wherein the phenolic resin powder is used as a binder, and the phenolic resin The powder accounts for 30% of the total mass fraction of the mixed powder. A porous graphite framework body with a positive gradient structure was prepared by selective laser sintering forming technology (such as figure 1 shown). From the surface to the inside, the graphite content decreases linearly, and the graphite distribution is relatively uniform on any cross-section. The graphite content in section 1 is 10% of the copper alloy mass fraction, the graphite content in section 2 is 6.5% of the copper alloy mass fraction, and the graphite content in section 3 is 3% of the copper alloy mass fraction. Section 1, Section 2 and Section 3 are friction and wear surfaces. Th...

Embodiment 2

[0029] Concrete preparation steps are as follows:

[0030] Step 1: Take graphite powder (250 mesh, purity 99.5%) and phenolic resin powder (800 mesh), mix them evenly and put them into a selective laser sintering molding machine, wherein the phenolic resin powder is used as a binder, and the phenolic resin The powder accounts for 50% of the total mass of the mixed powder. A porous graphite framework body with a positive gradient structure was prepared by selective laser sintering forming technology (such as figure 1 shown). From the surface to the inside, the graphite content decreases linearly, and the graphite distribution is relatively uniform on any cross-section. The graphite content in section 1 is 10% of the copper alloy mass fraction, the graphite content in section 2 is 6.5% of the copper alloy mass fraction, and the graphite content in section 3 is 3% of the copper alloy mass fraction. Section 1, Section 2 and Section 3 are friction and wear surfaces. The diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com