Composite frame system with beam column flanges being made of steel pipe concrete and construction method

A technology of steel pipe concrete and frame system, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of cumbersome construction, poor connection stability of composite structures, and easy damage of nodes, so as to achieve good overall structural continuity, shorten construction period, reduce workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

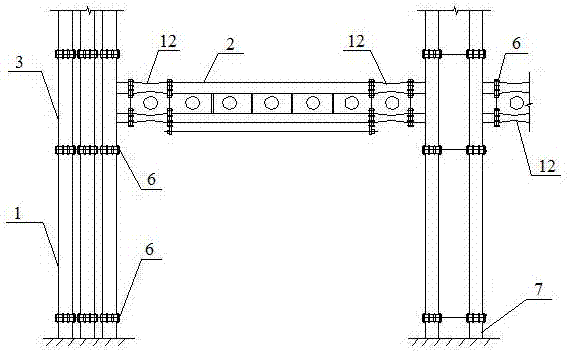

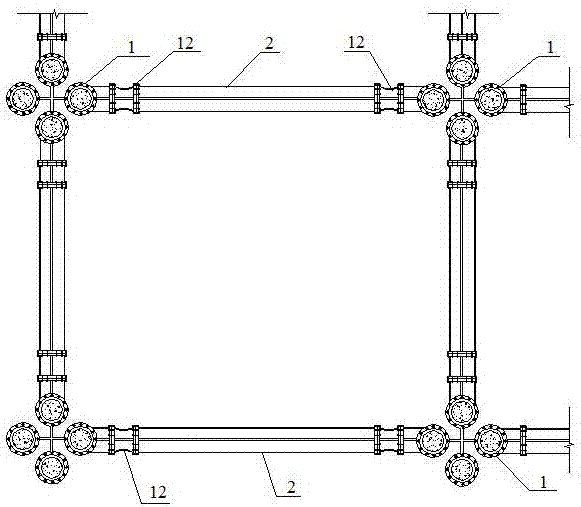

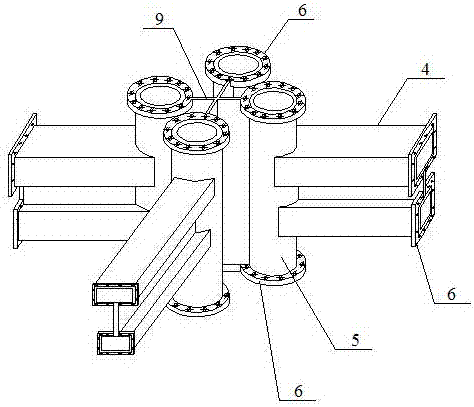

[0043] combine figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, the composite frame system with beam-column flanges made of concrete-filled steel tube is composed of composite column 1 and composite beam 2 connected by node 3, composite beam 2 is horizontally arranged between composite columns 1, node 3 is an integral node of steel tube concrete, and steel tube Concrete monolithic joints are welded together with I-shaped node end beams 4 whose upper and lower flanges are steel pipes and node end columns 5 whose flanges are circular steel pipes 8. The joints between I-shaped node end beams 4 and node end columns 5 The rectangular steel pipe 11 of the rectangular steel pipe 11 communicates with the circular steel pipe 8 to form a steel pipe integral joint. Pouring concrete 10; the composite column 1 is a cross-shaped composite column with a circular steel pipe concrete flange, and the two ends of the circular steel pipe ...

Embodiment 2

[0051] combine figure 1 , figure 2 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, the composite frame system with beam-column flanges made of concrete-filled steel tube is composed of composite column 1 and composite beam 2 connected by node 3, composite beam 2 is horizontally arranged between composite columns 1, node 3 is an integral node of steel tube concrete, and steel tube Concrete monolithic joints are welded together with I-shaped node end beams 4 whose upper and lower flanges are steel pipes and node end columns 5 whose flanges are circular steel pipes 8. The joints between I-shaped node end beams 4 and node end columns 5 The circular steel pipes 8 communicate with each other to form a steel pipe integral joint. The other end of the I-shaped joint end beam 4 is welded with the connecting plate 6, and the two ends of the joint end column 5 are respectively welded with the connecting plate 6. Concrete is poured in the steel pipe integra...

Embodiment 3

[0059] combine figure 1 , figure 2 , Figure 5 As shown, the composite column in this embodiment is a cross-shaped composite column whose flange is circular steel pipe concrete, and the integral joint of steel pipe concrete is an I-shaped node whose upper and lower flanges are circular steel pipes, and the end beams and flanges are circular steel pipes8 The cross-shaped node end column is welded into one, and the circular steel pipe 8 at the junction of the I-shaped node end beam and the node end column is connected to form a steel pipe integral node. The other end of the I-shaped node end beam is welded with a connecting plate. The two ends of the node end column 5 are respectively welded with the connection plate 6, and the concrete 10 is poured in the steel pipe integral node, and the other is the same as the embodiment 2.

[0060] The construction method of the composite frame system in which the above-mentioned beam-column flanges are steel tube concrete:

[0061]Firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com