Montmorillonite/rare-earth particle/polymer ternary nano composite material and its preparing method

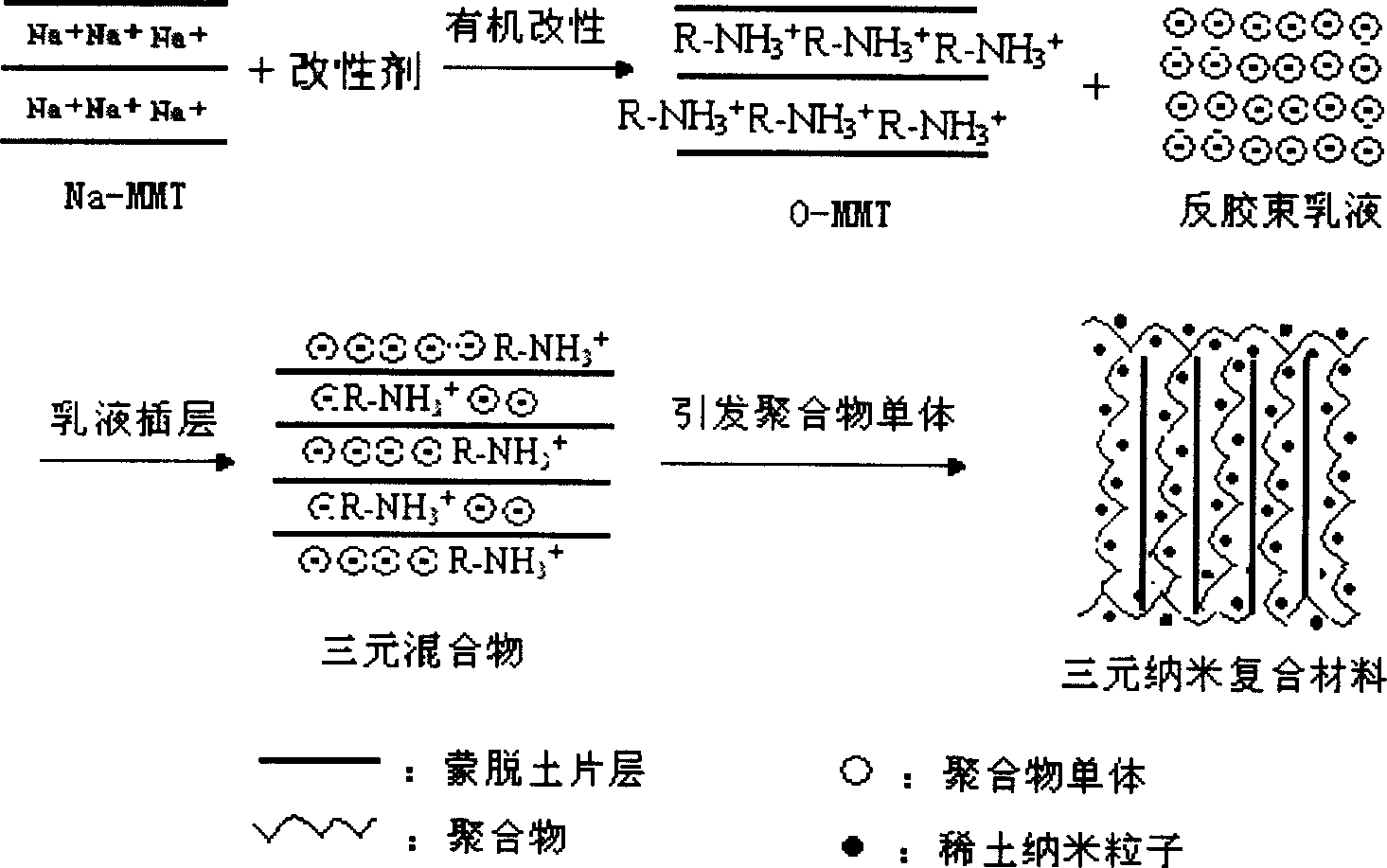

A nano-composite material and polymer technology is applied in the field of ternary composite material composed of montmorillonite, polymer and rare earth nanoparticles and the field of preparation thereof, and can solve the problems affecting the performance of the composite material, the non-uniformity of the composite system, and the montmorillonite flakes. Layer aggregation and other problems, to achieve the effect of high production efficiency, shortened preparation time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

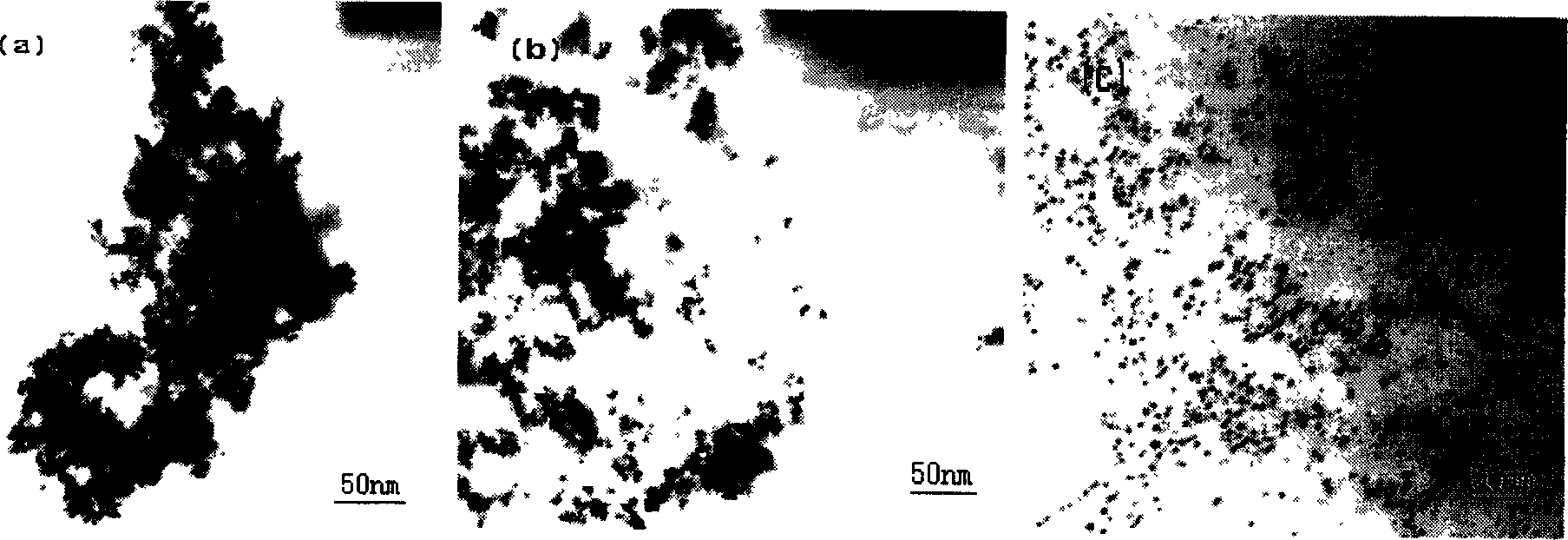

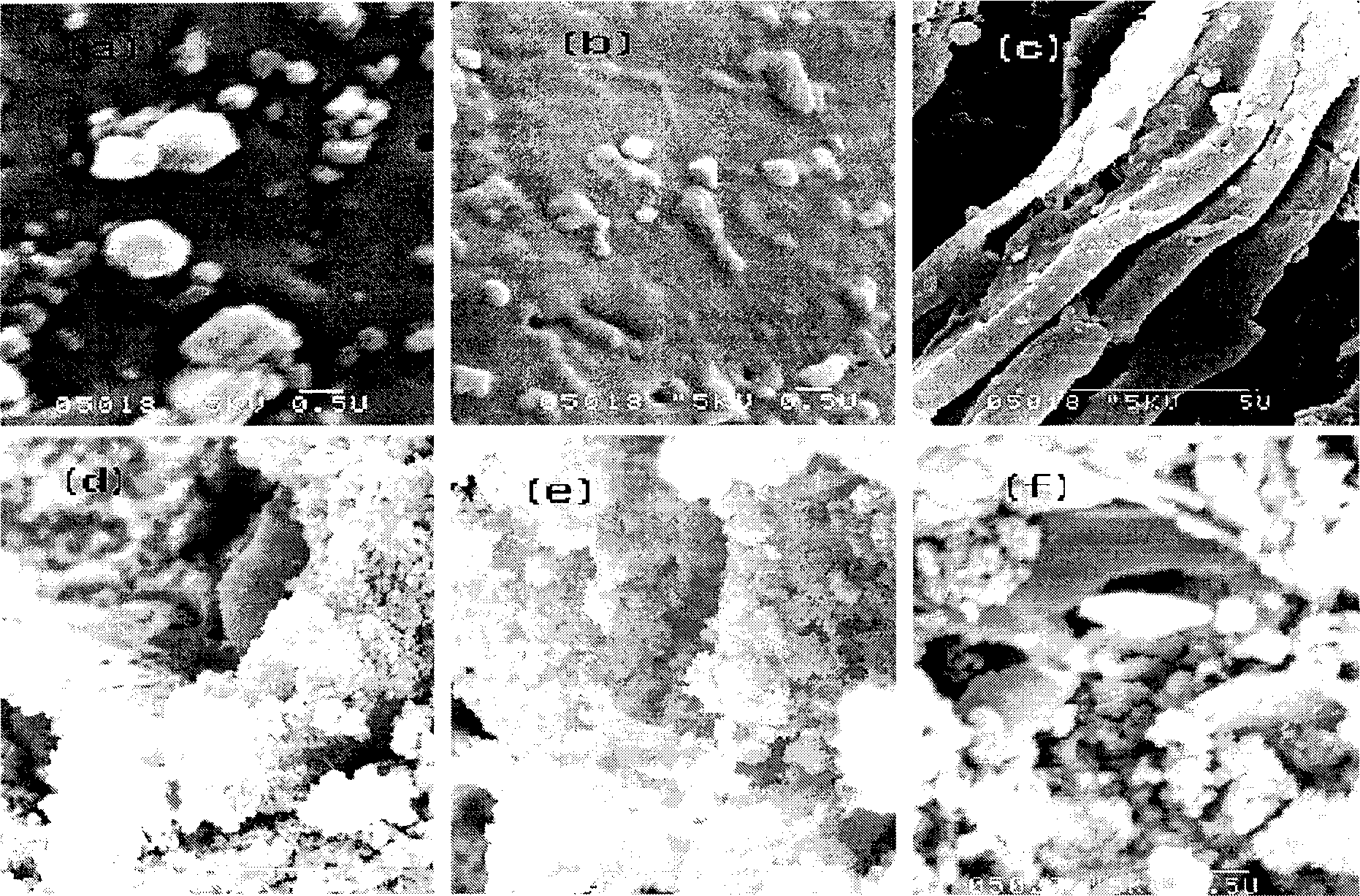

[0036] Example 1: Dissolve 100 parts of aniline, 10 parts of sulfosalicylic acid and 15 parts of sodium lauryl sulfate in 400 parts of water and stir evenly, then add 2 parts of EuCl 3 The aqueous solution was stirred, and ultrasonically dispersed at room temperature for 30 minutes to form a reverse micellar emulsion; 2 Add the reverse micellar emulsion drop by drop to the organic montmorillonite aqueous dispersion under protection, adjust the temperature to 60°C, disperse the intercalation with magnetic stirring for 2 hours, then lower the temperature, and move the reactants to an ice-water bath at about 0°C. Add 100 parts of ammonium persulfate initiator dropwise to initiate polymerization of polymer monomers, and add 3.5 times the amount of rare earth ion substance after 20 hours of reaction. Sodium hydroxide solution is added as a precipitant for rare earth nanoparticles, filtered and washed to obtain montmorillonite / Eu(OH) 3 / Polyaniline ternary nanocomposite.

[0037]...

Embodiment 2

[0038] Example 2. Dissolve 100 parts of methyl methacrylate and 10 parts of cetyltrimethylammonium chloride in 400 parts of chloroform and stir evenly, then add 5 parts of NdCl 3 The aqueous solution was stirred, and ultrasonically dispersed at room temperature for 35 minutes to form a reverse micellar emulsion; 2 Under protection, the reverse micellar emulsion was added dropwise to the aqueous dispersion of organic montmorillonite, the temperature was adjusted to 65°C, and magnetic stirring was used to disperse the intercalation for 2.5 hours, and then 0.1 part of azobisisobutyronitrile was added as an initiator to make the polymer The monomer initiates polymerization, and after 15 hours of reaction, add sodium hydroxide solution 3.5 times the amount of rare earth ion substance as a precipitant for rare earth nanoparticles, filter and wash to obtain montmorillonite / Nd(OH) 3 / Polymethyl methacrylate ternary nanocomposite.

[0039] Wherein the modification method of organic mo...

Embodiment 3

[0040] Example 3, dissolve 100 parts of methyl acrylate and 17 parts of stearic acid in 500 parts of chloroform and stir evenly, then add 10 parts of LaCl 3 The aqueous solution was stirred, and ultrasonically dispersed at room temperature for 40 minutes to form a reverse micellar emulsion; 2 Add the reverse micellar emulsion dropwise to the aqueous dispersion of organic montmorillonite under protection, adjust the temperature to 70°C, disperse the intercalation with magnetic stirring for 3 hours, and then add 1 part of azobisisobutyronitrile as an initiator to make the polymer The monomer initiates polymerization, and after 20 hours of reaction, 3.5 times the amount of rare earth ion substance is added into a sodium hydroxide solution as a precipitant for rare earth nanoparticles, filtered and washed to obtain montmorillonite / La(OH) 3 / polymethylacrylate ternary nanocomposite.

[0041] Wherein the modification method of organic montmorillonite is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com