Recycled concrete precast floor slab structure and manufacturing method

A technology of recycled concrete and production methods, which can be applied to floors, building components, manufacturing tools, etc., can solve the problems of increasing the cost of building products and aggravating environmental pollution, and achieve the effects of easy construction quality assurance, environmental protection, and simple on-site assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

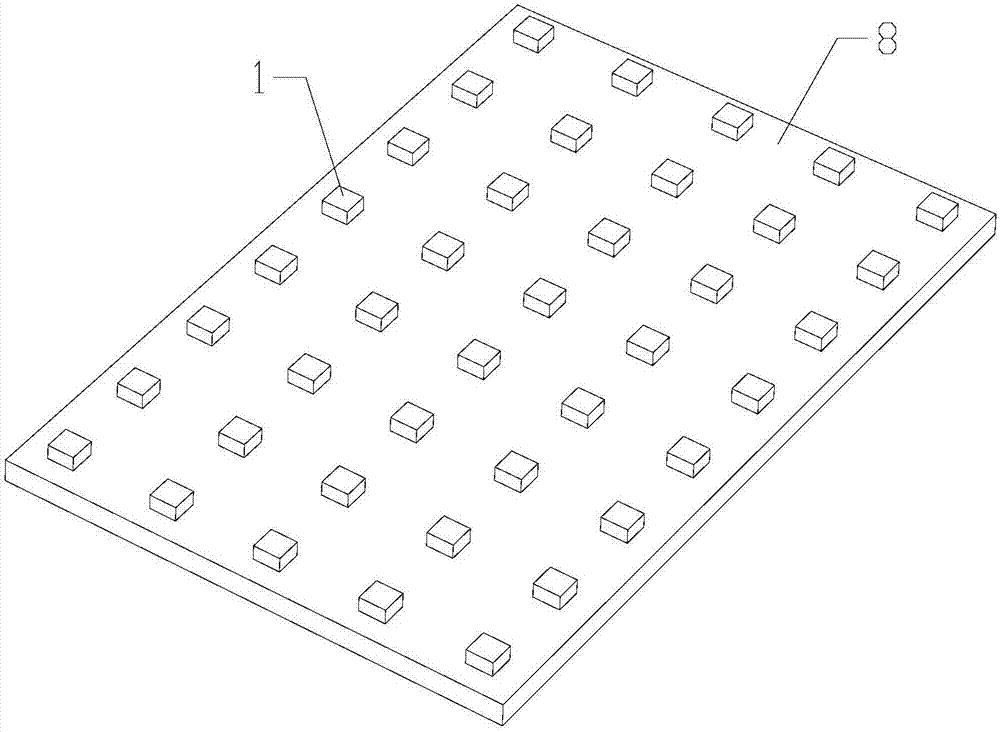

[0028] Such as Figure 1-Figure 7 As shown, the recycled concrete prefabricated floor slab of the present invention has two structural forms, namely recycled concrete laminated floor slab and recycled concrete fully prefabricated floor slab.

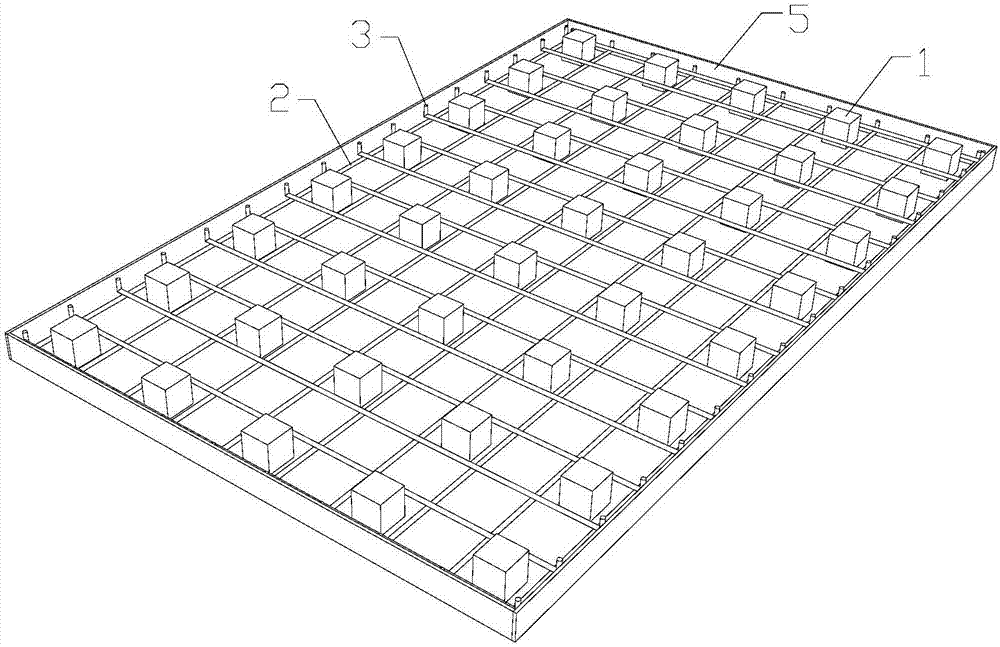

[0029] (1) If Figure 1-Figure 5 As shown, the recycled concrete laminated floor structure and manufacturing method are as follows:

[0030] (1) if figure 2 As shown, the size of the formwork 5 is determined according to the size of the recycled concrete laminated floor slab, the longitudinal reinforcement 2 and the transverse reinforcement 3 are arranged in the formwork first, and then the precast concrete shear key block 1 is arranged according to the shear force and tension to be borne by the shear key ,form figure 2 Structure.

[0031] (2) at figure 2 Recycled concrete is poured on the foundation, and the height of the prefabricated floor is half of the height of the recycled concrete laminated slab. After the recycled concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com