Lightweight electric vehicle

A light-weight technology for electric vehicles, applied to vehicle parts, load-bearing body structures, superstructures, etc., can solve the problems of low strength and rigidity of the chassis, occupying space in the cab, unsafe batteries, etc., and achieve weight reduction and overall structure Optimize and expand the effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

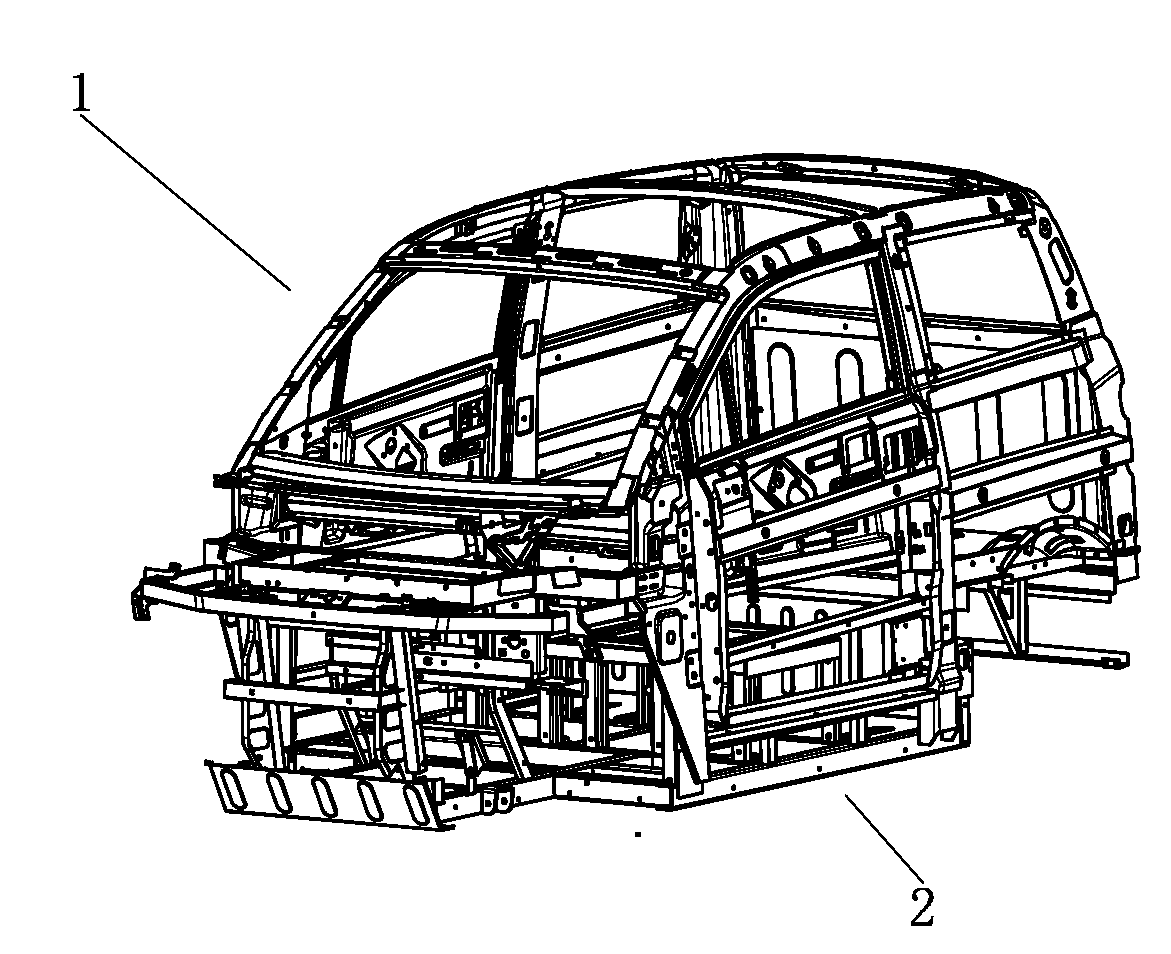

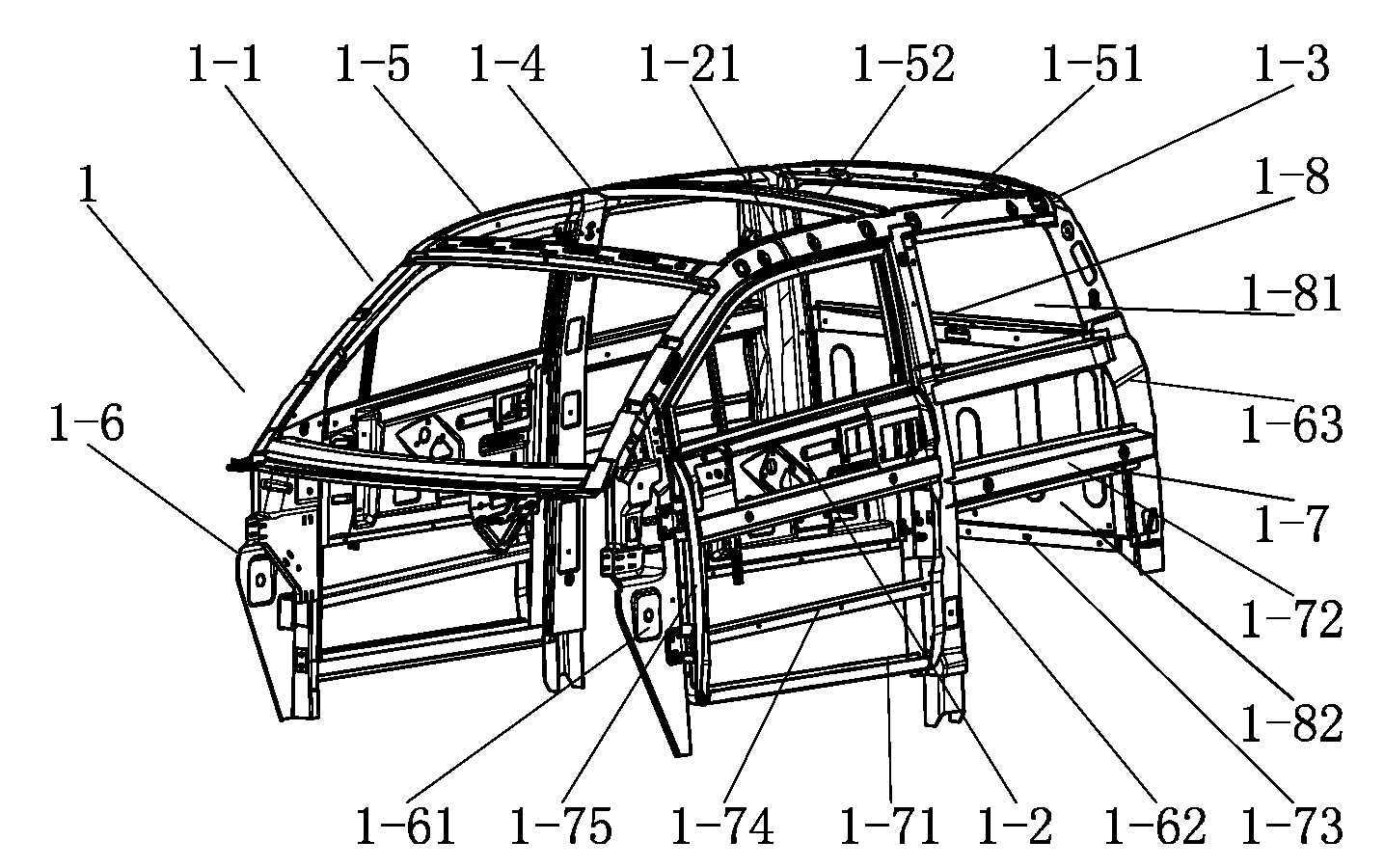

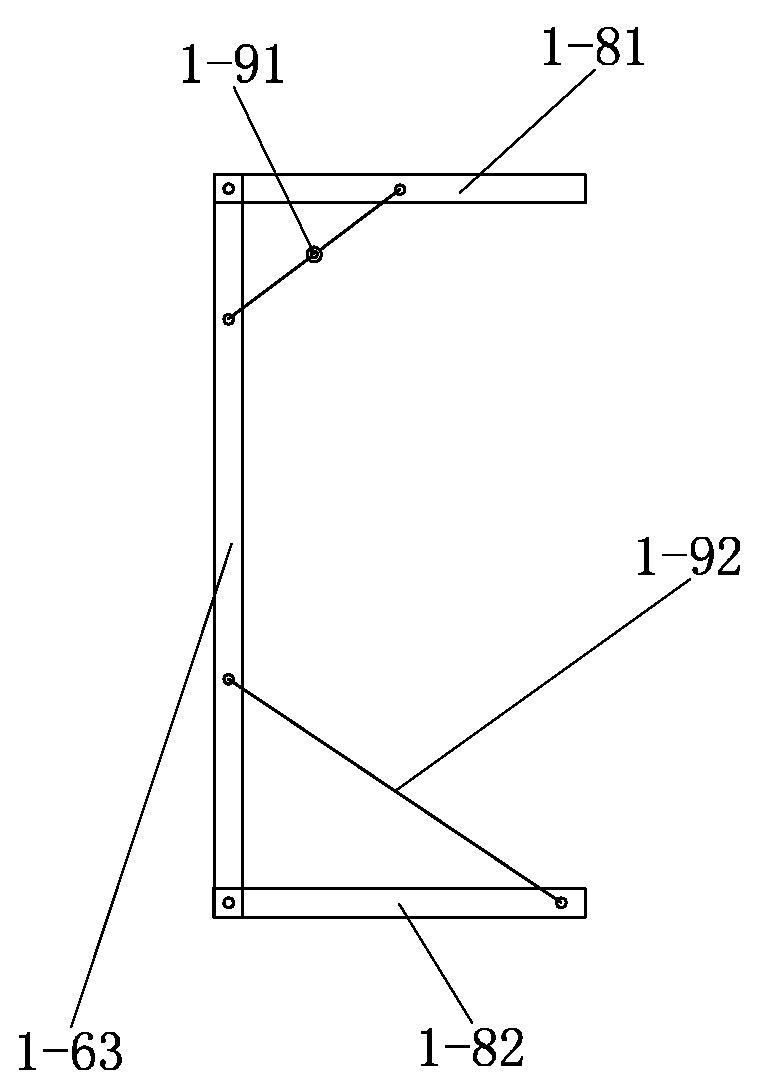

[0033] Such as figure 1 , figure 2 and Figure 4 As shown, the lightweight electric vehicle of this embodiment includes a body structure 1 of the electric vehicle and a frame structure 2 connected to the lower part of the body structure 1. The body structure 1 includes a body 1-1 and a door 1-2. The body 1-1 and the door 1-2 are composed of a framework 1-3 and a thermoplastic plate (not shown in the figure) covering the inner and outer surfaces of the framework; Composition: A battery compartment 2-2 is provided in the middle of the beam frame 2-1. Of course, as a lightweight electric vehicle, it also includes power supply, drive motor, motor speed control device, transmission device, driving device, steering device, braking device, etc. in the prior art.

[0034] Because the technical solution adopts the technical means that the body and the door are composed of a skeleton and a thermoplastic plate covering the surface of the skeleton, it can not only ensure the strength,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com