Multifunctional complex printer

A printing machine, multi-functional technology, applied in the direction of printing machine, rotary printing machine, printing, etc., can solve the problems of complex structure of satellite self-adhesive printing machine, can not change the paper feeding mode, single paper feeding mode, etc., and achieve structural The effect of simplicity, increased cost, and flexible printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

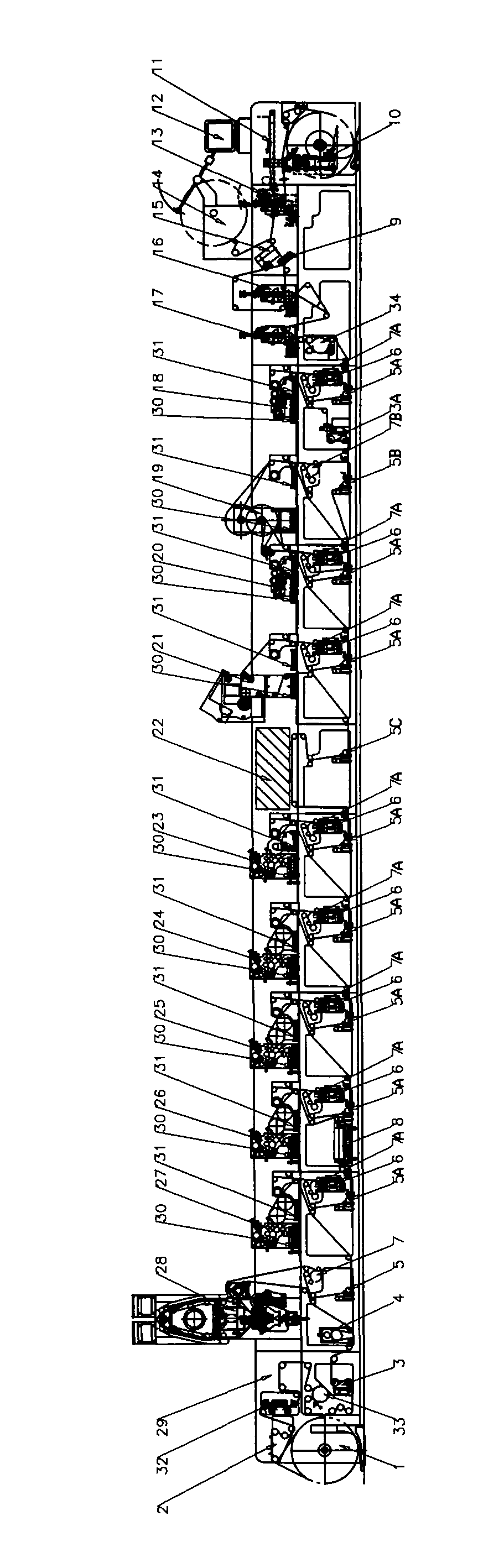

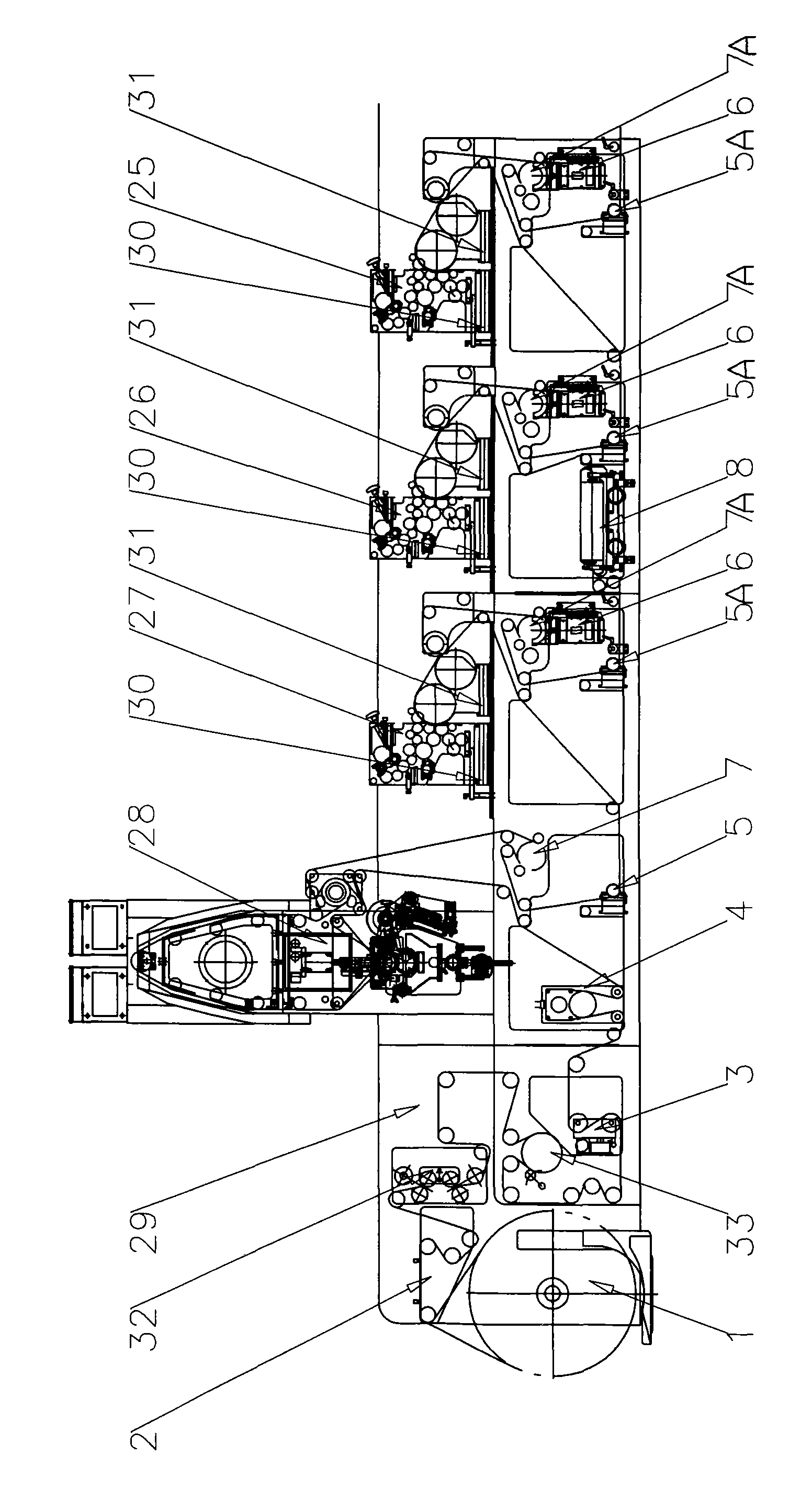

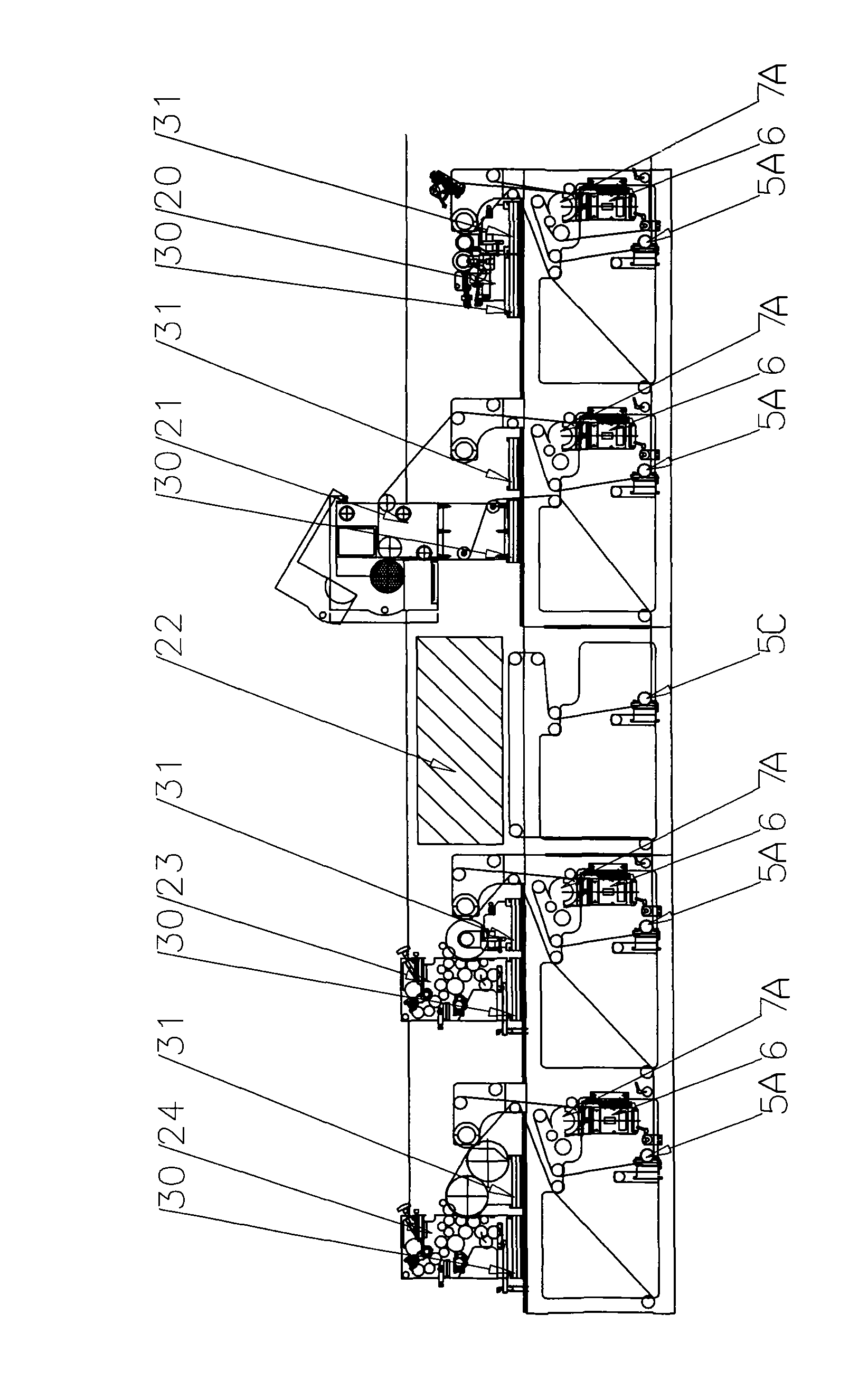

[0025] Such as figure 1 As shown, it is a structural schematic diagram of a multifunctional composite printing machine provided by the present invention, Figure 1A to Figure 1C Represent three parts of the present invention respectively, will Figure 1A to Figure 1C The three parts in the sequence are connected head to tail, which is figure 1The device shown includes the paper feeding part 1. The roll paper of the paper feeding part 1 is strung on the paper feeding shaft. The gear side end of the paper feeding shaft is installed with a bearing, and then connected with the gear side wallboard. It is located at the leftmost end of the machine. . There is a paper receiving table 2 above the paper feeding section 1, which is a platform type and is directly installed on the paper feeding section wallboard by screws. There is a base paper correction device 32 on the right side of the paper receiving table 2, which is mainly used to correct the flatness of the roll paper. It is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com