Pushing and drawing force testing machine

A push-pull force tester and pull test technology, which is applied in the direction of impact test, machine/structural component test, static/dynamic balance test, etc. It can solve the problems of difficult test process and poor repeatability of control test results, and achieve thrust and The pulling force is controllable, the operation is convenient, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

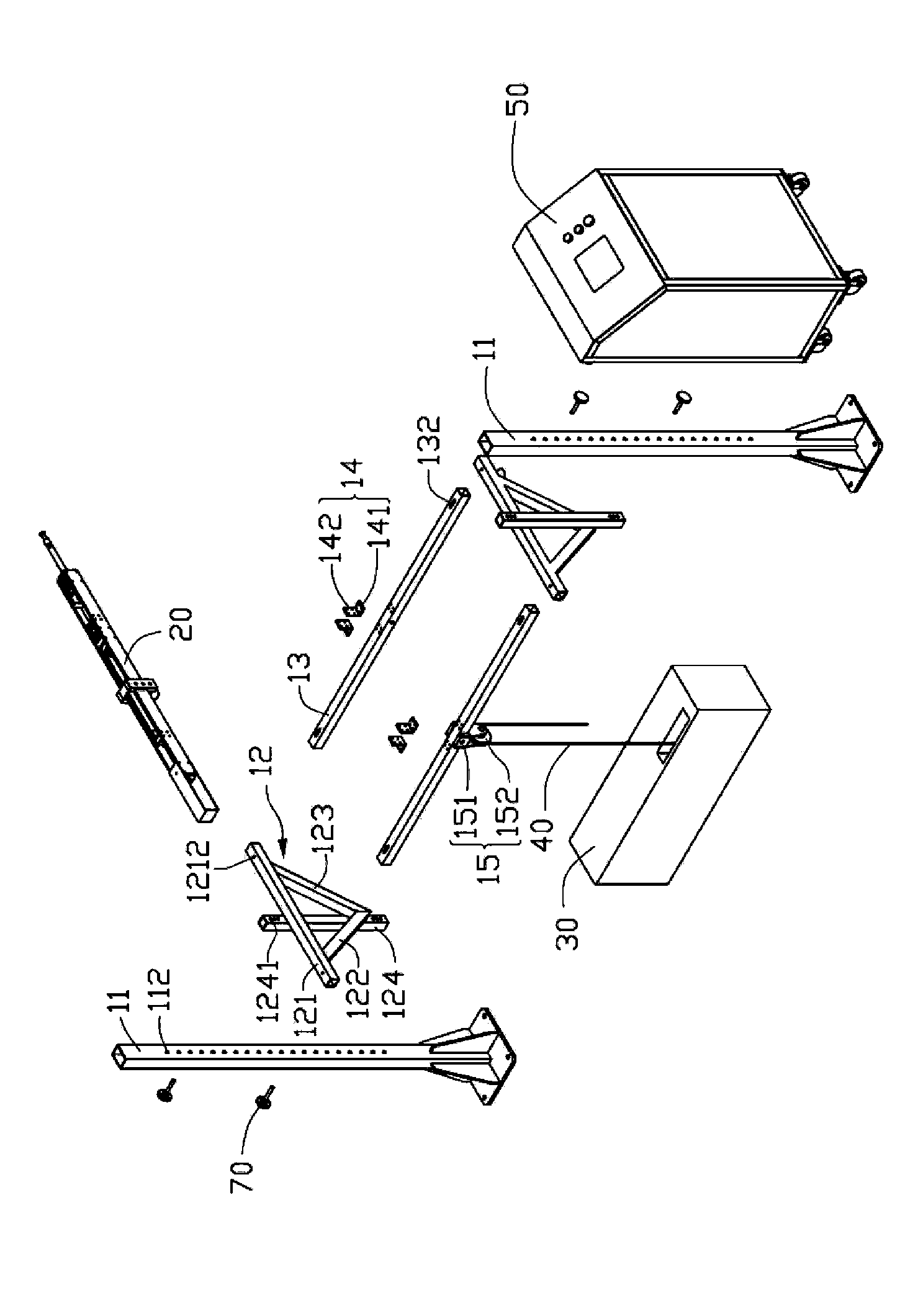

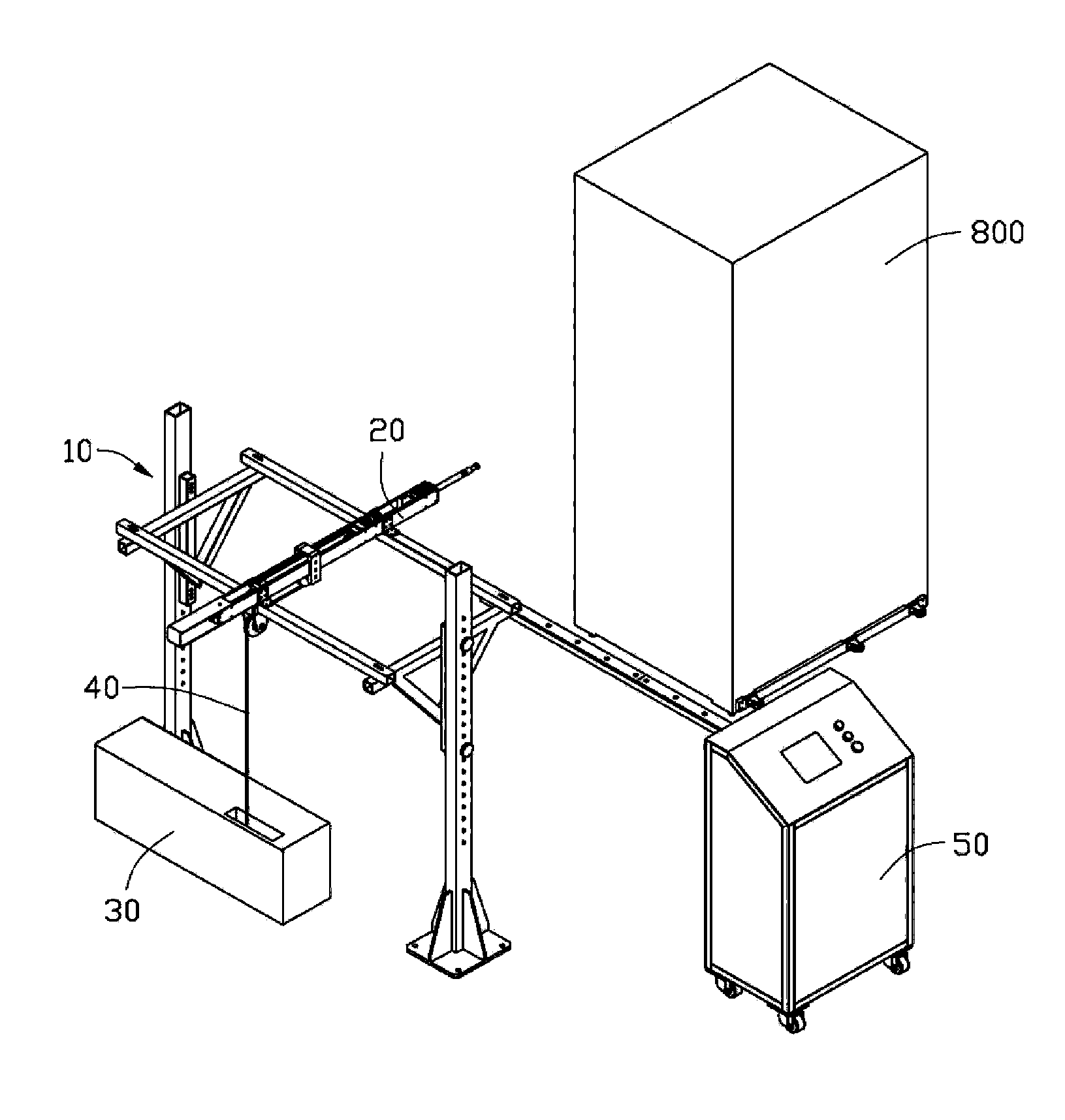

[0013] see Figures 1 to 3 , the push-pull force testing machine of the present invention is used to perform a push-pull force test on an electronic device 800 . The push-pull force testing machine includes a support device 10 , a push-pull force conversion mechanism 20 , a force applying device 30 , a rope 40 and a controller 50 . In this embodiment, the electronic device 800 is a server.

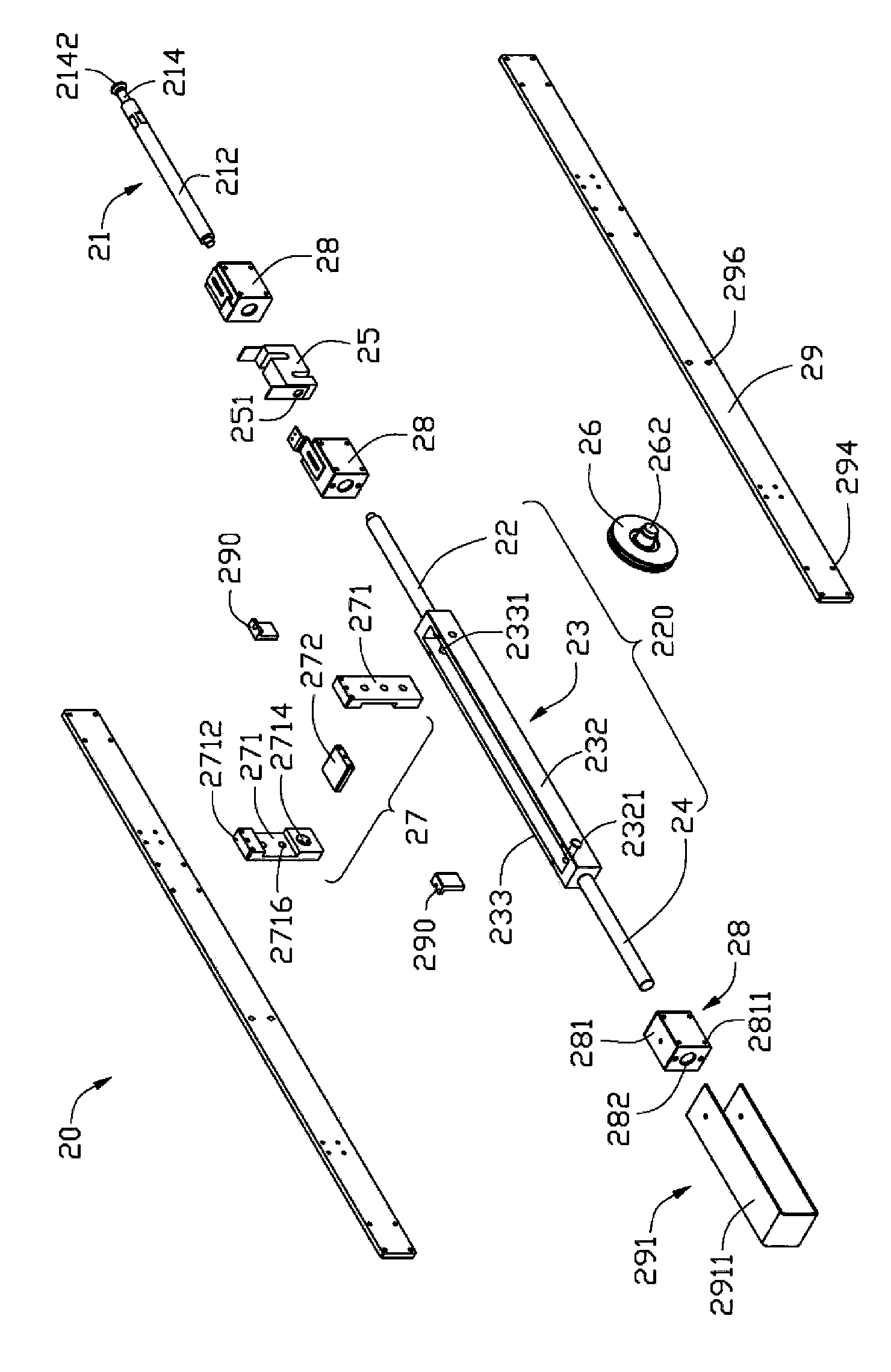

[0014] The supporting device 10 includes a pair of uprights 11 , a pair of supporting parts 12 , a pair of supporting rods 13 , two pairs of fixing parts 14 and a hanging part 15 . Two opposite sides of each column 11 are respectively provided with a plurality of fixing holes 112 along its longitudinal direction. Each bearing member 12 is triangular in shape and includes a first rod 121 , a second rod 122 and a third rod 123 connected end to end. A mounting portion 124 is further defined on a side of the supporting member 12 . The mounting portion 124 defines a plurality of threaded ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com