Floating net cage underwater easily disassembled binding structure

A technology that is easy to disassemble and cage, applied in the field of cages, can solve the problems of poor flow resistance, troublesome operation, large volume loss, etc., and achieve the effect of convenient daily carrying and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

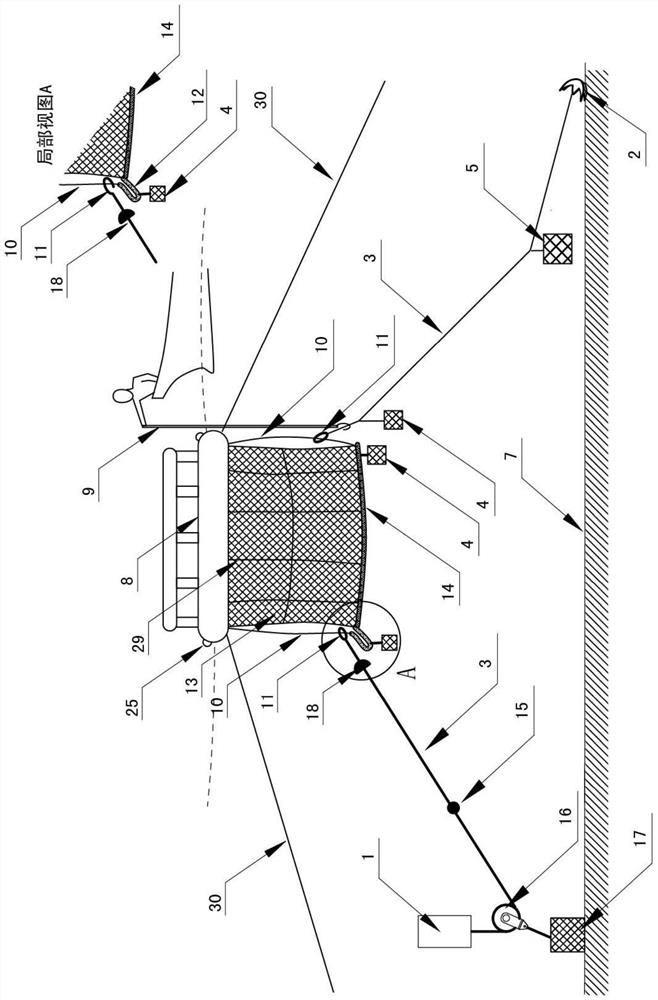

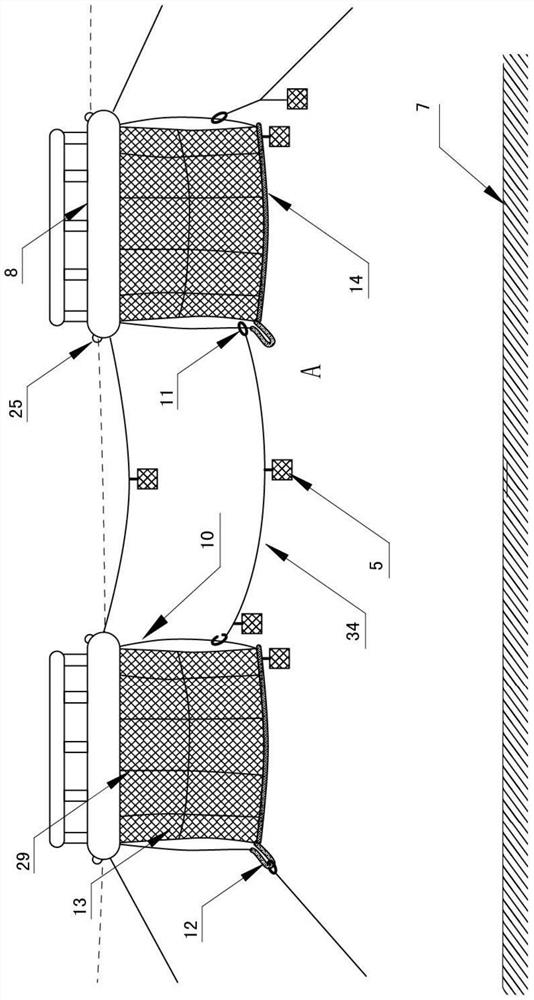

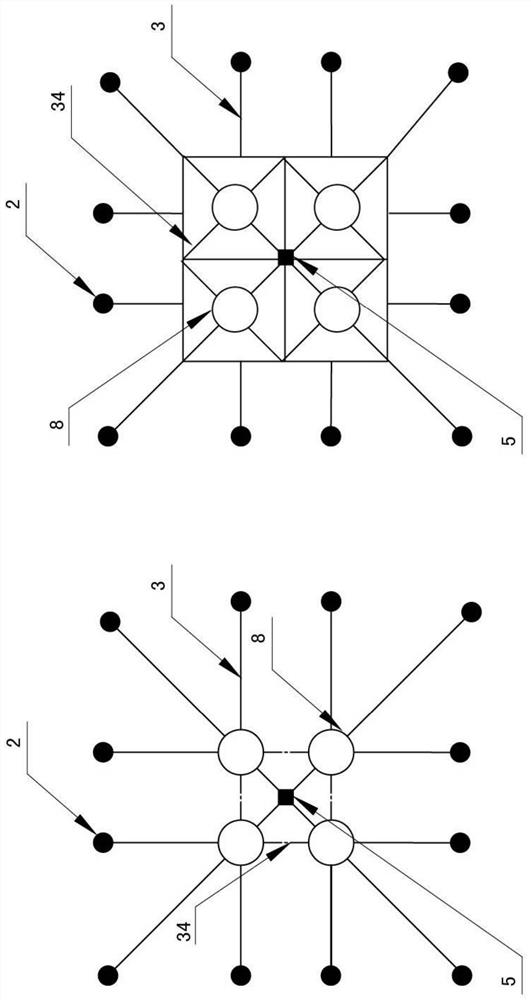

[0059] Further description will be made below in conjunction with the accompanying drawings.

[0060] figure 1 It is the schematic diagram of the anchoring and release at the bottom of the cage. The figure shows two mooring methods. The lower left side is the mooring method of the submersible pulley, and the lower right side is the mooring method of heavy objects buffer. In actual application, the floating cage The mooring method should only be adopted in one way, that is, the top and bottom ends of the floating cage are either anchored by the anchor unit moored by the submersible pulley, or anchored by the heavy buffer mooring method. For the convenience of explanation, it does not mean that a floating cage adopts two mooring methods at the same time.

[0061]In the figure, a guide rope 10 is arranged on the outside of the net cage. One end of the guide rope 10 is tied to the floating pipe frame 8 at the upper end of the net cage or to the mesh bar 29 at the top of the net. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com