Sample preparing and tensioning equipment for performance testing of tensile sample strip of carbon fiber multifilament

A tensioning device and carbon fiber technology, which are applied in the preparation of test samples, the use of stable tension/pressure to test the strength of materials, sampling, etc., can solve the problems of difficulty in tensioning and straightening of carbon fiber tows, and achieve the transmission structure setting. Simple and reasonable, easy to tension, ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

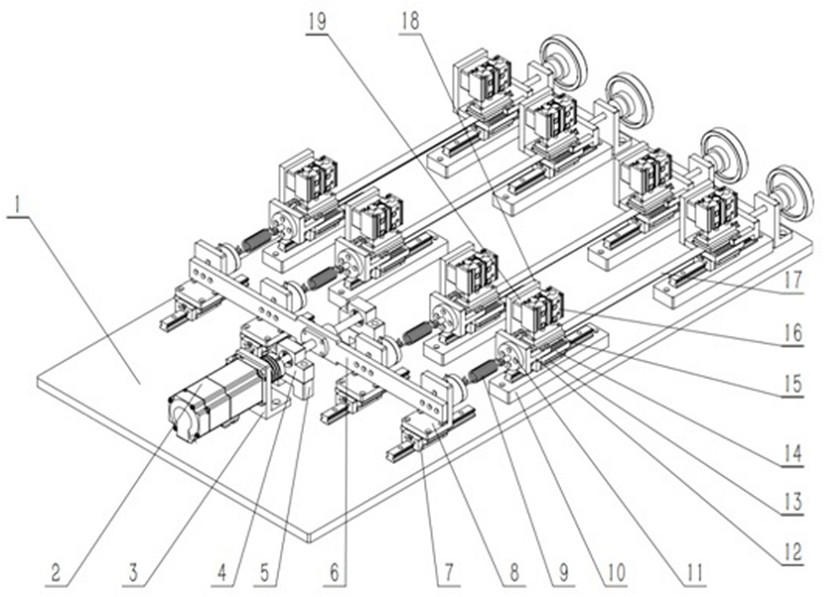

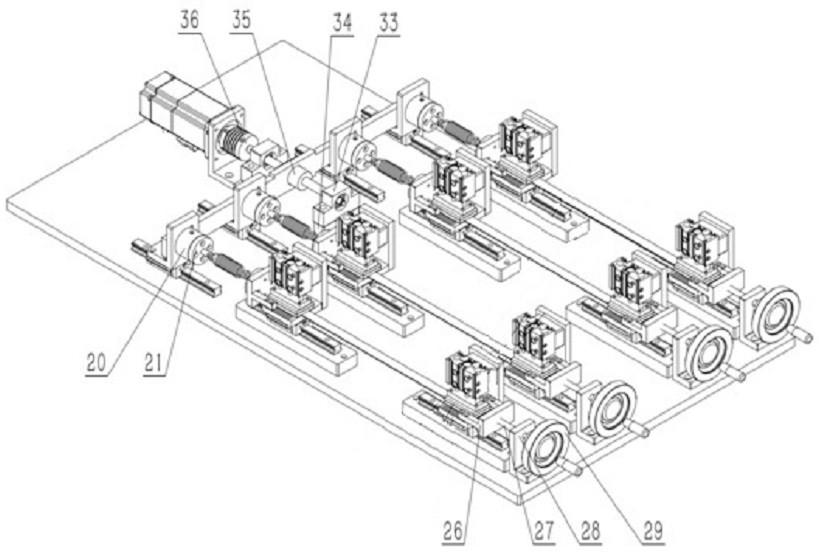

[0032] A kind of carbon fiber multifilament stretching sample performance testing sample tensioning equipment of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0033] Such as figure 1 and figure 2 As shown, a carbon fiber multifilament tensile sample tensioning device for performance testing of the present invention includes a bottom plate 1 arranged horizontally. The base plate 1 is provided with a stretching module, and the stretching module includes a first compression assembly and a second compression assembly for fixing the carbon fiber tow 17, and the first compression assembly and the second compression assembly are arranged at intervals left and right, At least one group of the first pressing assembly and the second pressing assembly is provided with a sliding assembly so that the pressing assembly provided with the sliding assembly can move in the direction in which the carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com