A micro-glass tube automatic threading and centering device and method

A glass tube and automatic threading technology, which is applied to the suspension wire of the inertial pendulum part of the micro-miniature accelerometer, the automatic threading and centering of the glass tube, and the automatic threading and centering device of the micro glass tube, which can solve the problem of low assembly accuracy, platinum Problems such as wire surface damage and low degree of automation can be achieved, and the assembly force can be controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

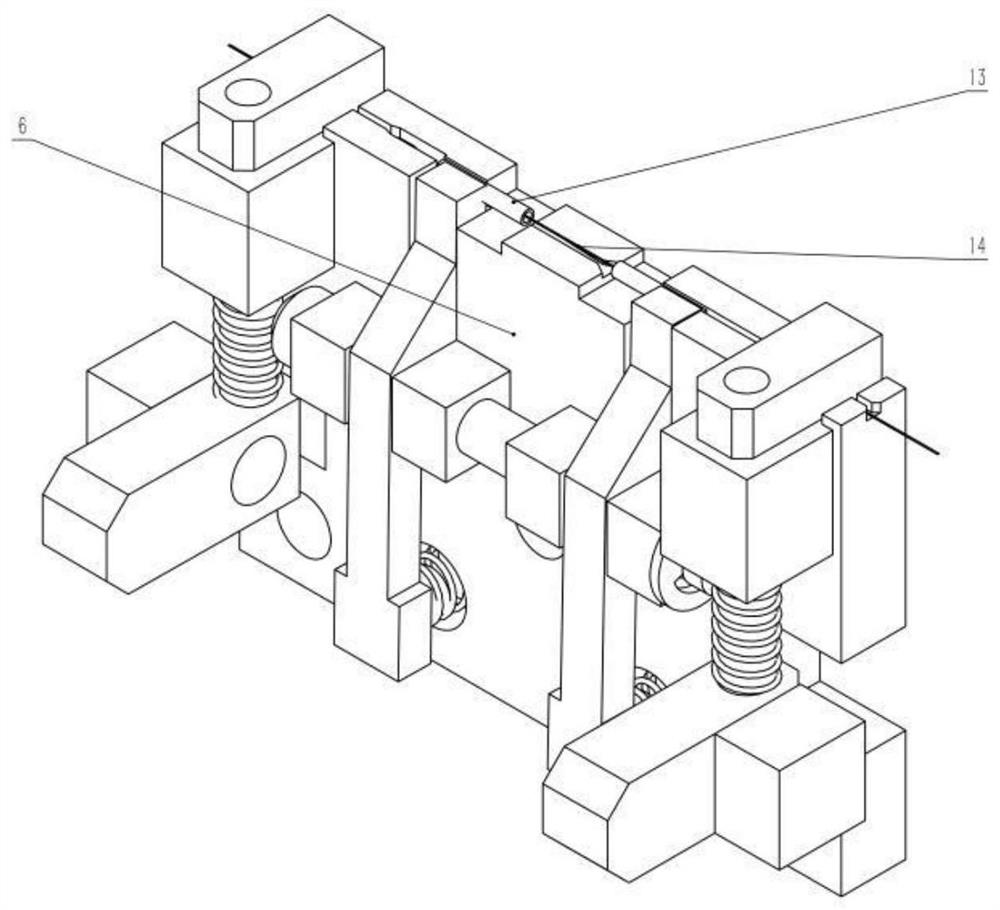

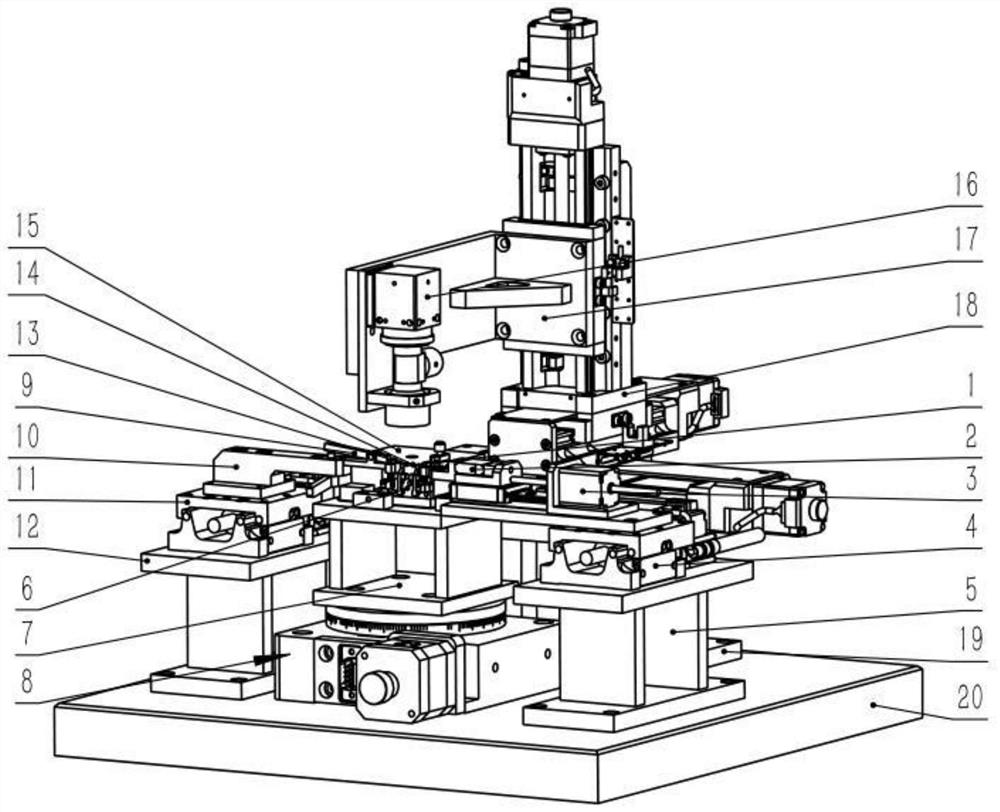

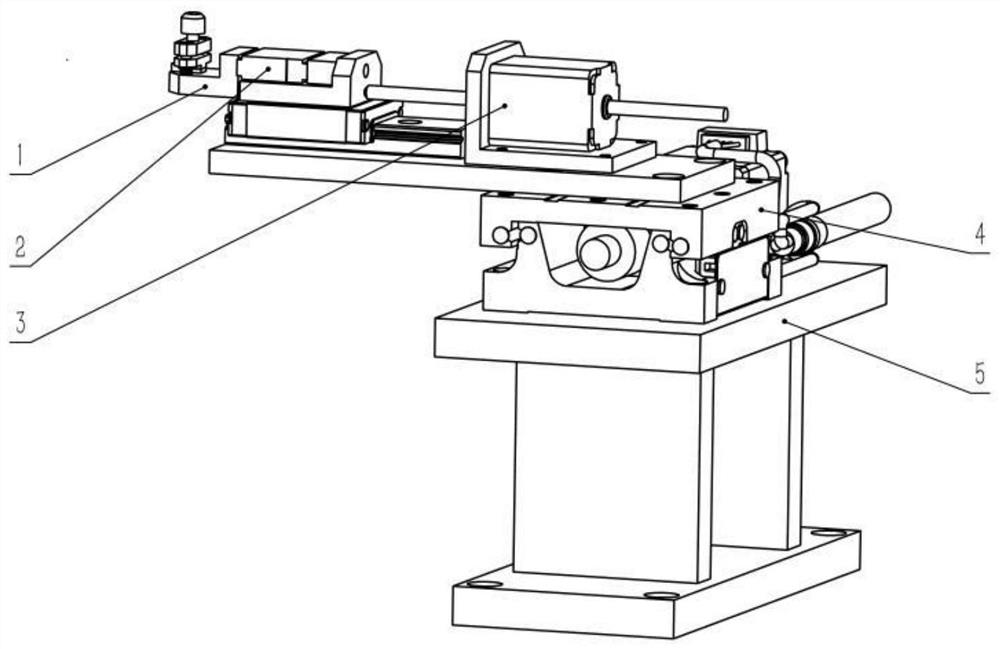

[0024] Such as figure 1 In the shown glass tube clamp 6, two glass tubes 13 are installed on the glass tube clamp 6 before threading. Such as Figure 2a , Figure 2b , Figure 2c , Figure 2d with Figure 2e As shown in the structural diagram of the device, the glass tube fixture 6 is vertically installed on the glass tube fixture mounting platform 15, and then the glass tube fixture mounting platform 15 is clamped on the fixture mounting platform support 7 by screws. Through the rotation adjustment of the precision turntable 8 and the movement adjustment of the right precision displacement platform 4, the clamp mouth of the right suspension wire clamp 1 is aligned with the suspension wire guide groove of the glass tube clamp 6 (the suspension wire guide groove is a bell mouth) Accurately, install one end of the suspension wire 14 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com