Cloth wrinkle removing treatment device for garment making

A processing device and cloth technology, which are applied in the direction of fabric elongation, textile and papermaking, fabric surface trimming, etc., can solve the problem of difficulty in controlling the stretching force of the cloth, improve the efficiency of flattening and wrinkle removal, easy to control the tension, and save time. and energy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

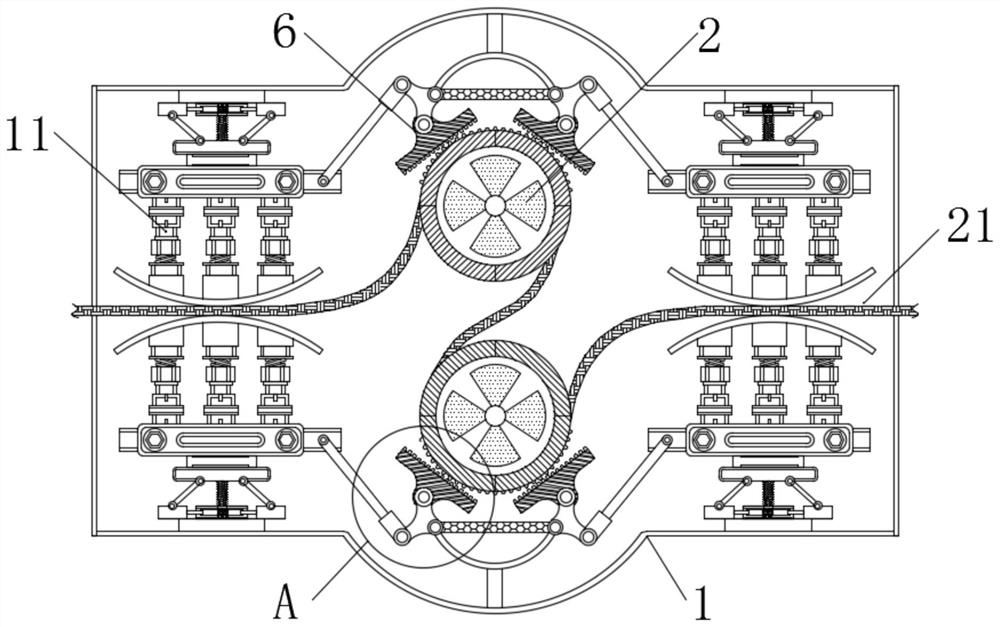

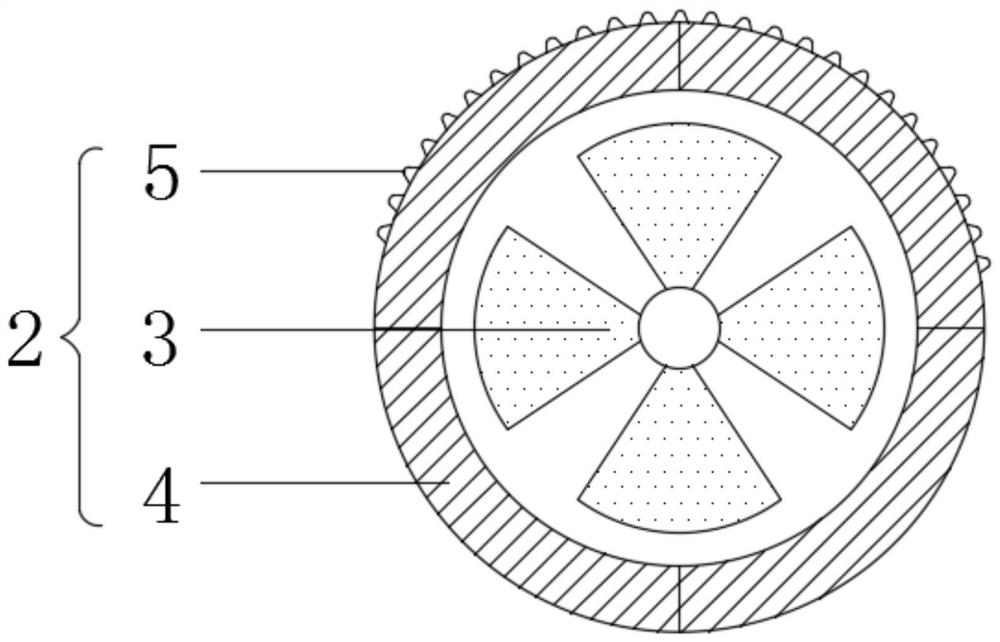

[0025] see figure 1 and figure 2 , a cloth wrinkle-removing treatment device for clothing production, comprising a casing 1, the inside of the casing 1 is movably connected with a cloth cloth mechanism 2, the cloth cloth mechanism 2 includes a turning hand 3, and the outer surface of the turning hand 3 is fixedly connected with a roller shaft 4. A rack plate 5 is fixedly connected to one side of the outer surface of the roller shaft 4, and a pressure mechanism 6 is engaged with the outer surface of the rack plate 5 and located on both sides of the roller shaft 4, and the cloth 21 is wound around the roller shaft 4 in a zigzag manner. The outer surface of the can increase the length of the fabric flattened in a single pass,

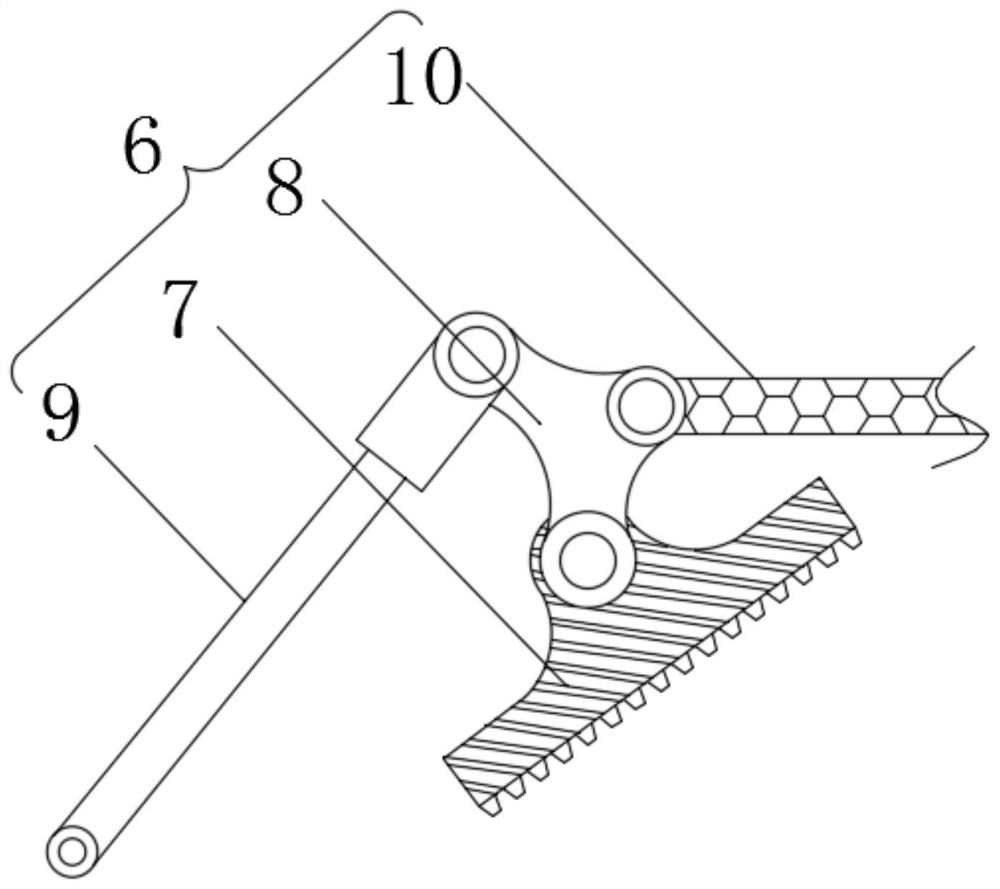

[0026] Further, the pressure mechanism 6 includes a toothed plate 7, the toothed plate 7 and the outer surface of the rack plate 5 are engaged with each other, the outer surface of the toothed plate 7 is fixedly connected with a triangular plate 8, and o...

Embodiment 2

[0029] see figure 1 and Figure 4 and Figure 5 , a cloth wrinkle-removing treatment device for clothing production, comprising a casing 1, the inside of the casing 1 is movably connected with a cloth cloth mechanism 2, the cloth cloth mechanism 2 includes a turning hand 3, and the outer surface of the turning hand 3 is fixedly connected with a roller shaft 4. A rack plate 5 is fixedly connected to one side of the outer surface of the roller shaft 4, and a pressure mechanism 6 is engaged with the outer surface of the rack plate 5 and located on both sides of the roller shaft 4, and the cloth 21 is wound around the roller shaft 4 in a zigzag manner. The outer surface of the can increase the length of the fabric flattened in a single pass.

[0030] Further, the clamping mechanism 11 includes a pressure plate 12, one end of the pressure rod 9 is fixedly connected with the outer surface of the pressure plate 12, and a first pressure block 13 is fixedly connected to one side of t...

Embodiment 3

[0033] see Figure 1-5, a cloth wrinkle-removing treatment device for clothing production, comprising a casing 1, the inside of the casing 1 is movably connected with a cloth cloth mechanism 2, the cloth cloth mechanism 2 includes a turning hand 3, and the outer surface of the turning hand 3 is fixedly connected with a roller shaft 4. A rack plate 5 is fixedly connected to one side of the outer surface of the roller shaft 4, and a pressure mechanism 6 is engaged with the outer surface of the rack plate 5 and located on both sides of the roller shaft 4, and the cloth 21 is wound around the roller shaft 4 in a zigzag manner. The outer surface of the toothed plate 7 can increase the length of the cloth flattened at a time. The pressure mechanism 6 includes a toothed plate 7. The toothed plate 7 and the outer surface of the rack plate 5 are engaged with each other. The outer surface of the toothed plate 7 is fixedly connected with a triangular plate 8. The triangular plate One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com