Spandex-free elastic denim fabric manufacturing method and denim fabric

A technology of denim fabrics and production methods, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, textiles, etc., can solve the problems of denim clothing such as slippery, elastic, and affecting wearing comfort, and achieve easy tension Effects of control, enhanced water absorption, and easier quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

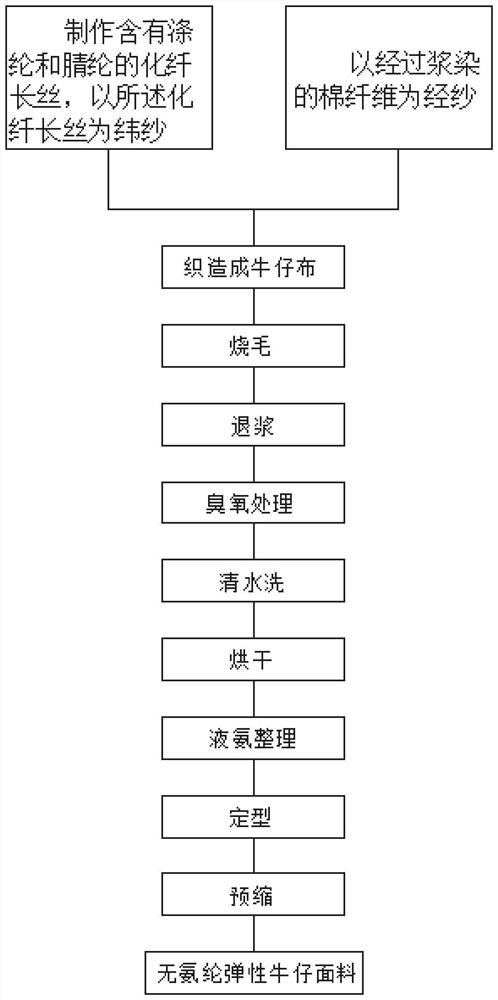

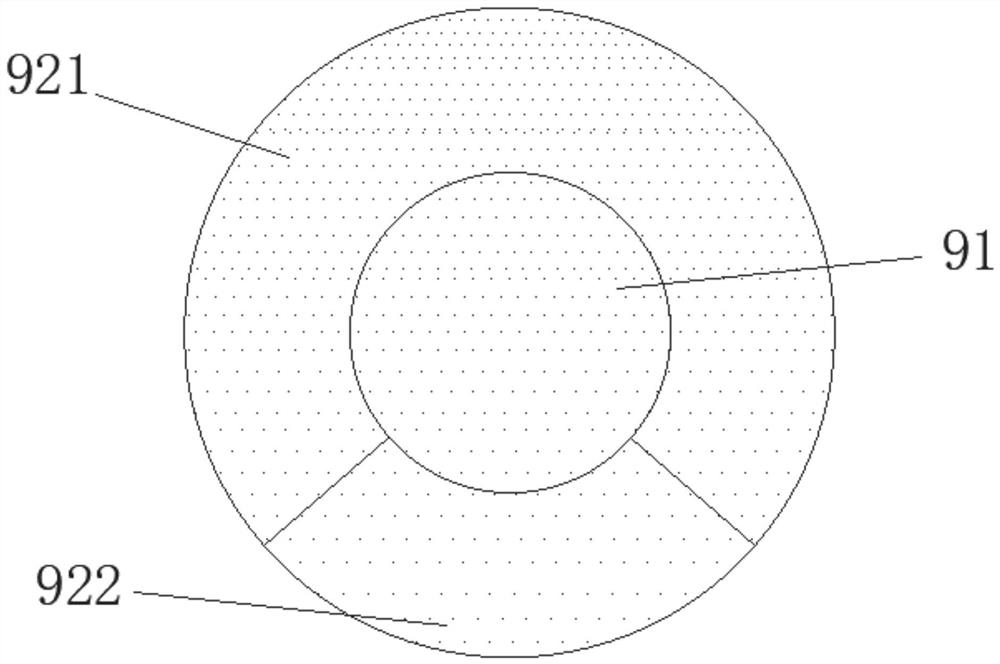

[0043] use as figure 2 The spinneret shown is used to produce chemical fiber filaments containing polyester and acrylic fibers, and the spinneret holes in the center ring 91 extrude acrylic fibers; the spinneret holes in the inferior arc section 922 are used to extrude PET melt, which is mixed with 0.5% of oxalic acid; the spinneret hole in the superior arc section 921 is used to extrude an equal mixture of PET melt and PTT melt, which is mixed with 1% oxalic acid. The chemical fiber filament was introduced into a hot-roll FDY spinning machine, the cooling temperature was 25°C, the speed of the first roller was 2100m / min, the temperature of the first roller was 70°C, the speed of the second roller was 2960m / min, the temperature of the second roller was 125°C, and the winding speed was 2910m / min; the temperature of the relaxation heat treatment is 104° C. and the time is 30 minutes, and the chemical fiber filament after the relaxation heat treatment is obtained.

[0044] The...

Embodiment 2

[0046] Polyester is extruded from PET melt and PTT melt in a side-by-side composite spinning process. The ratio of the number of spinnerets for extruding the PET melt in the spinneret to the number of spinnerets for extruding the PTT melt is 1:2. 1% oxalic acid and 1% malonic acid were added to the PET melt, and 0.5% oxalic acid and 0.5% malonic acid were added to the PTT melt. The chemical fiber filament was introduced into a hot-roll FDY spinning machine, the cooling temperature was 25°C, the speed of the first roller was 2100m / min, the temperature of the first roller was 70°C, the speed of the second roller was 2960m / min, the temperature of the second roller was 125°C, and the winding speed was 2910m / min; the temperature of the relaxation heat treatment is 104° C. and the time is 30 minutes, and the chemical fiber filament after the relaxation heat treatment is obtained.

[0047] The sizing and dyed cotton fibers are taken as warp yarns, and the chemical fiber filaments a...

Embodiment 3

[0049] use as figure 2 The spinneret shown is used to produce chemical fiber filaments containing polyester and acrylic fibers, and the spinneret holes in the center ring 91 extrude acrylic fibers; the spinneret holes in the inferior arc section 922 are used to extrude PET melt, which is mixed with 1% of oxalic acid; the spinneret hole in the superior arc section 921 is used to extrude an equal mixture of PET melt and PTT melt, which is mixed with 2% oxalic acid. The chemical fiber filament was introduced into a hot-roll FDY spinning machine, the cooling temperature was 25°C, the speed of the first roller was 2100m / min, the temperature of the first roller was 70°C, the speed of the second roller was 2960m / min, the temperature of the second roller was 125°C, and the winding speed was 2910m / min; the temperature of the relaxation heat treatment is 104° C. and the time is 30 minutes, and the chemical fiber filament after the relaxation heat treatment is obtained.

[0050] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com