Fruit peeling machine

A technology of peeling machine and fruit, which is applied in the fields of dehydration preservation of fruits/vegetables, food preparation, food science, etc. It can solve the problems of high operation requirements for workers, uneven peeling thickness, poor appearance consistency, etc., and achieve peeling thickness The effect of uniformity, good appearance consistency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

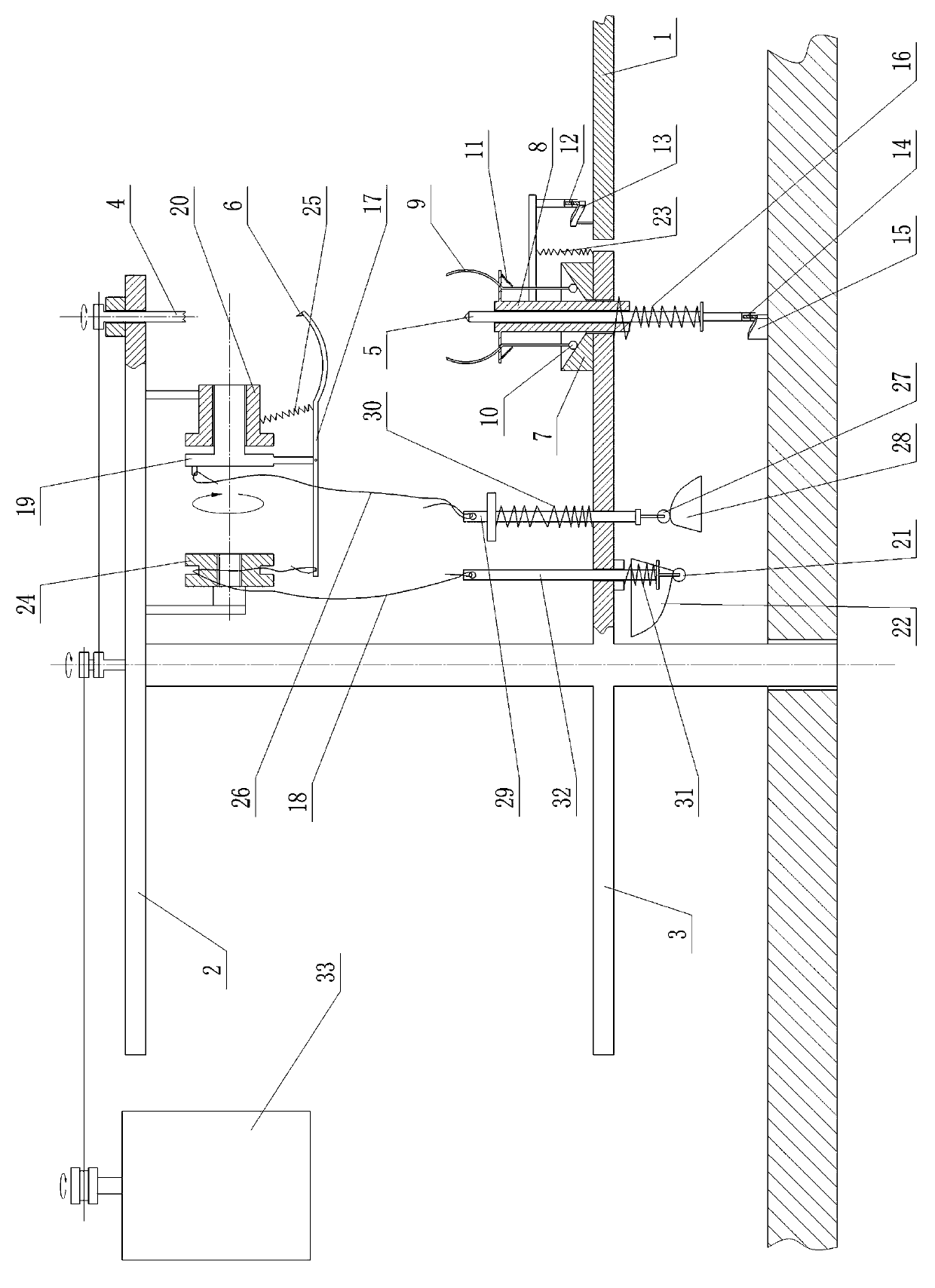

[0022] refer to figure 1 , a fruit peeler comprising

[0023] On the upper turntable 2, rotatable upper thimbles 4 are evenly arranged on the upper turntable 2, and each upper thimble 4 is respectively connected with the power mechanism;

[0024] The lower turntable 3, the lower turntable 3 is set under the upper turntable 2, the lower turntable 3 is provided with a grabber corresponding to each upper thimble 4, and the middle part of the grabber is provided with a corresponding upper thimble 4 that can move up and down. The lower thimble 5;

[0025] Next to the lower end of the upper thimble 4, there is a blade 6 that can move according to an arc trajectory;

[0026] The upper turntable 2 and the lower turntable 3 are connected with the power mechanism, and the upper turntable 2 and the lower turntable 3 rotate synchronously.

[0027] The upper thimble 4 is connected with the rotating shaft of the upper rotating disk 2 through a transmission belt, and the rotating shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com