Special PP protecting membrane formula for ITO

A protective film and formulation technology, applied in the field of polymer film formulation, can solve the problems of insufficient self-adhesive force, poor weather resistance, poor temperature resistance, etc., to improve temperature resistance, scratch resistance and corrosion resistance, resistance The effect of increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

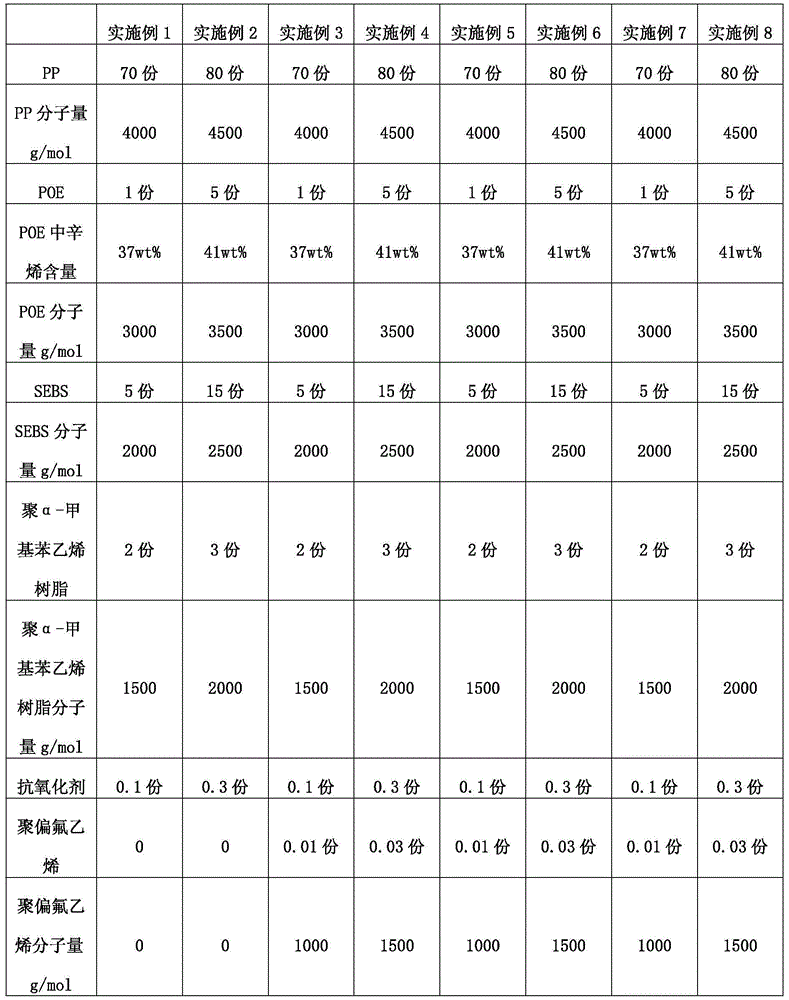

[0025] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

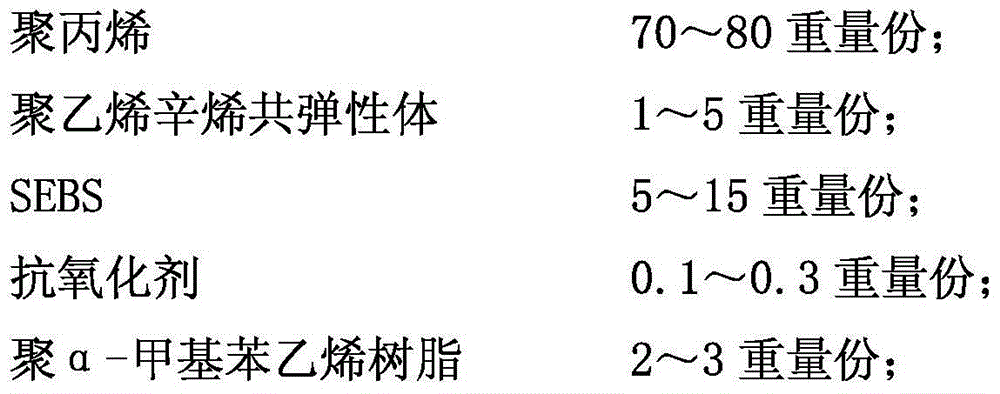

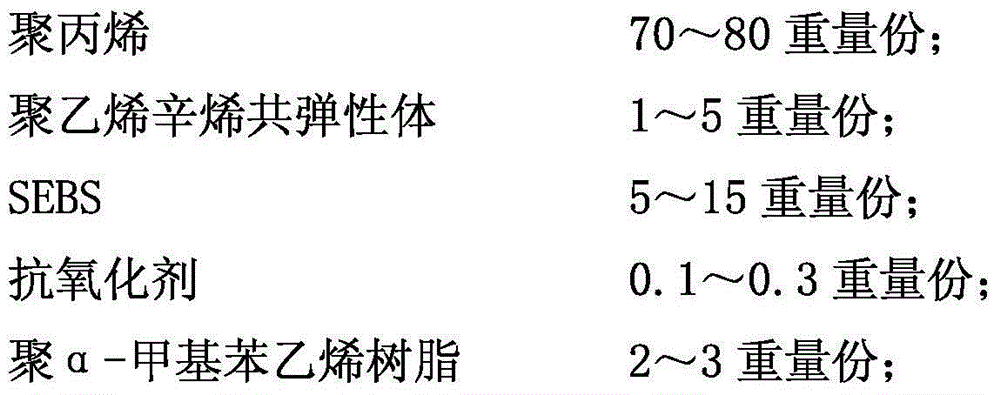

[0026] This case proposes an ITO-specific PP protective film formulation of an embodiment, including the following materials by weight:

[0027]

[0028] Wherein, in the polyethylene octene co-elastomer (POE), the content of octene is 37wt%-41wt%. In the POE used in this case, it is only necessary to limit the content of octene, and there is no need to specifically limit the type and composition of its block distribution. All commercially available products with an octene content within the set range can meet the requirements of this case. The coiled structure of soft chains in octene can not only improve the temperature resistance of the film but also adjust the viscosity of SEBS. However, the content of octene in POE should be limited, otherwise it will seriously affect its own ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com