Lithium ion battery core package, lithium ion battery and preparation method of lithium ion battery

A technology of lithium-ion batteries and core packs, applied in the manufacture of electrolyte batteries, batteries, secondary batteries, etc., can solve the problem that high-temperature tape 2 is difficult to protect, and achieve the effect of improving the appearance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

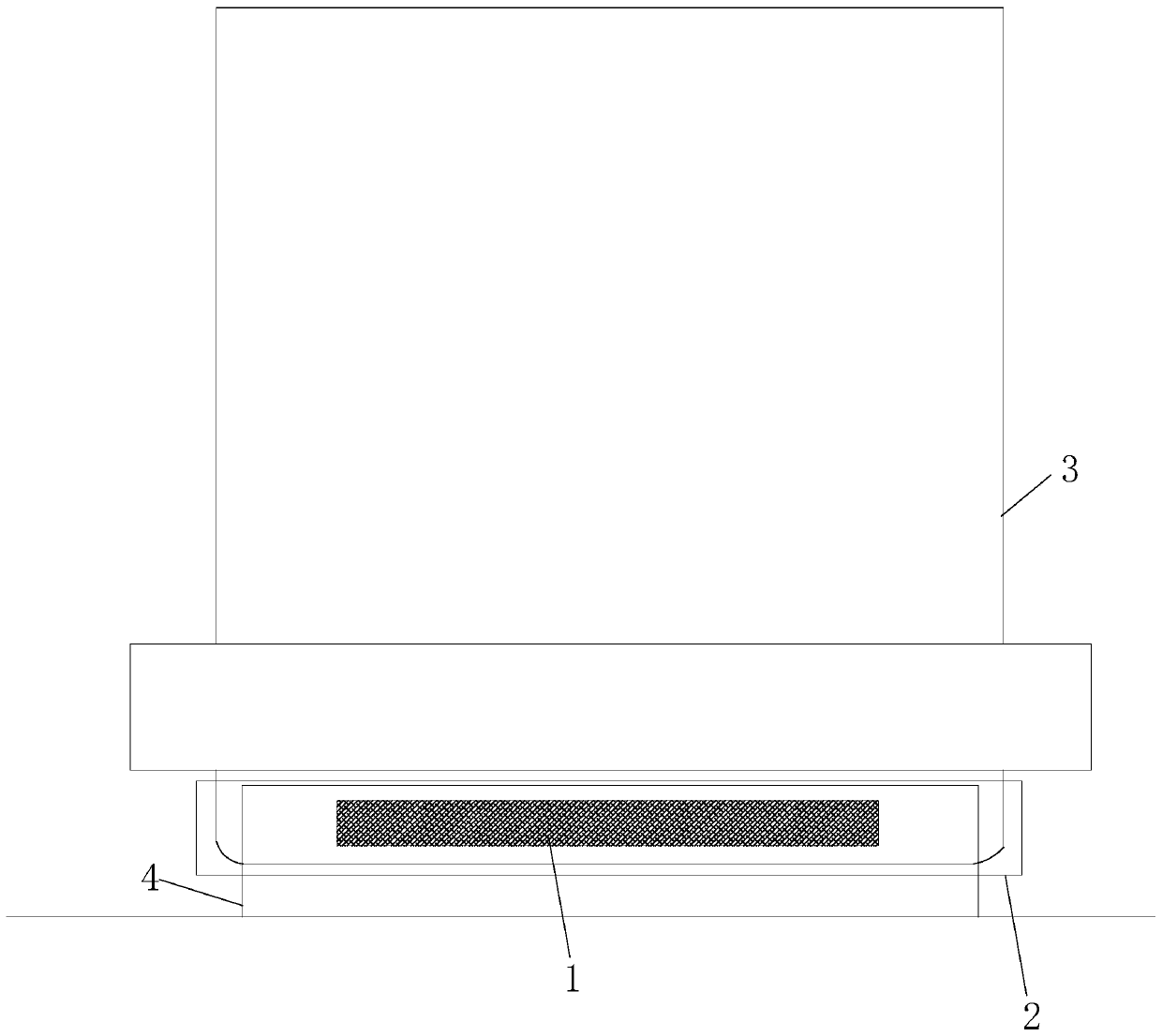

[0045]The lithium-ion battery pack provided in this embodiment mainly includes a laminated body, and the laminated body is mainly composed of a positive electrode sheet, a negative electrode sheet, and a diaphragm spaced between adjacent positive electrode sheets and negative electrode sheets, wherein the diaphragm can be an independent diaphragm layer, It is also possible to use a long sheet-shaped diaphragm to be spaced in a zigzag shape between each adjacent positive electrode sheet and negative electrode sheet, wherein the width of the negative electrode sheet is slightly wider than that of the positive electrode sheet, and the separator is equal to or slightly larger than the width of the negative electrode sheet.

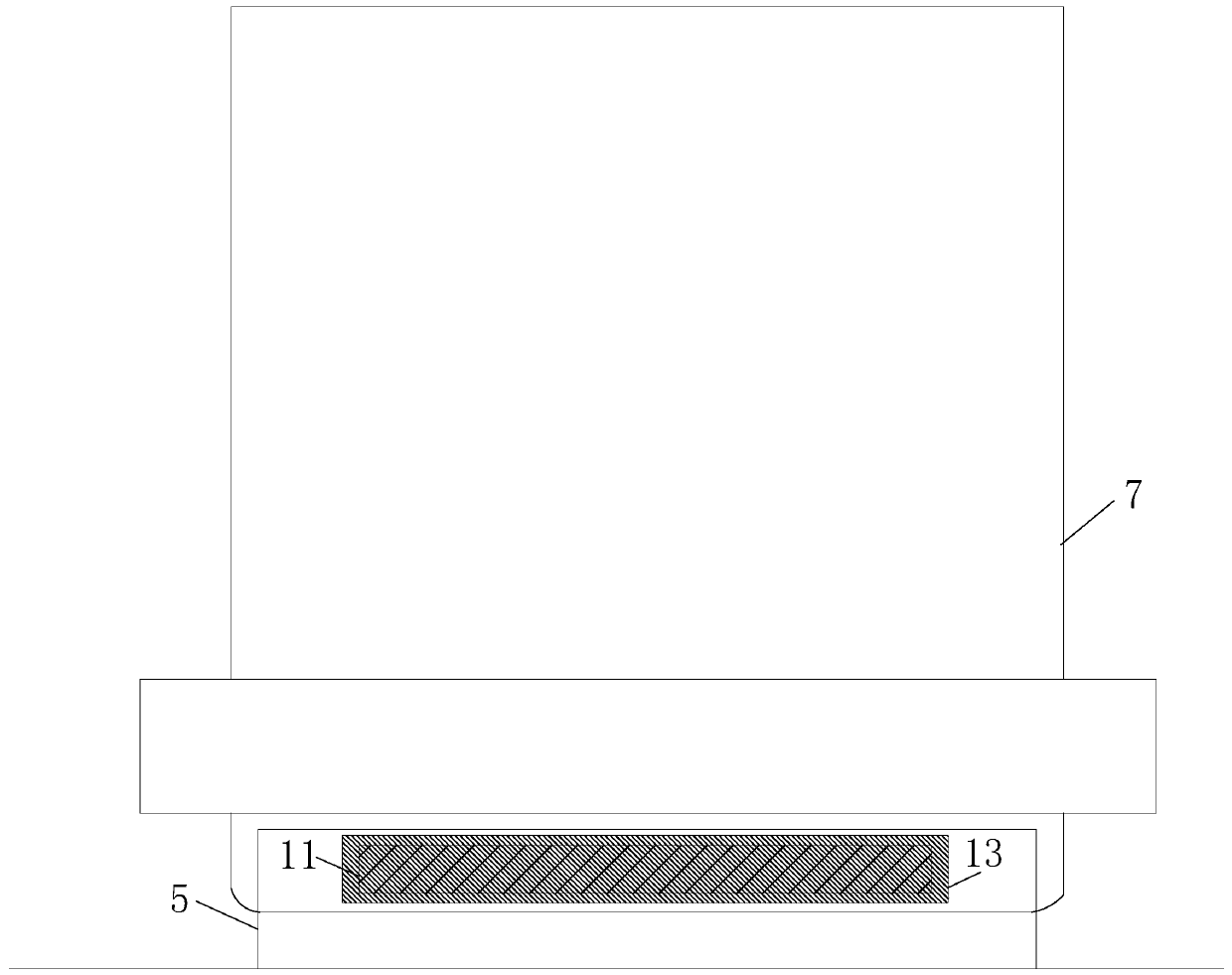

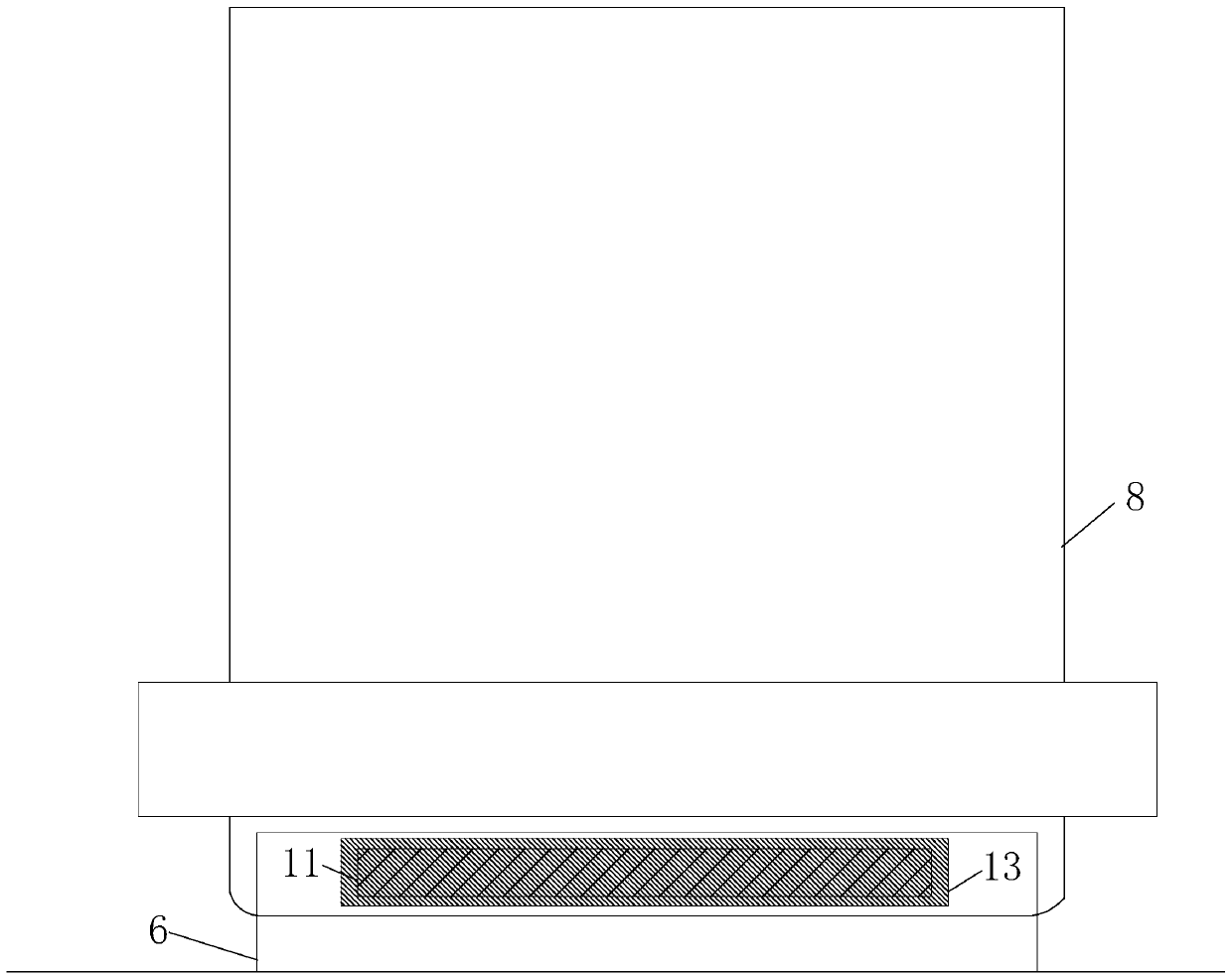

[0046] see figure 2 As shown, outside the active material coating area of each positive electrode sheet, there is also reserved a positive electrode ear welding part 5 protruding from the laminated body and integrated with the current collector of the positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com