Cap sealing pipe automatic forming device and forming method

A technology of automatic forming and forming methods, which is applied in the direction of tubular objects, metal processing, and other household appliances, etc., which can solve the problems of affecting appearance, low efficiency, inconsistent product appearance, etc., and achieve the effect of high appearance consistency and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

[0028] see Figure 1 to Figure 3 , the embodiment of the present invention provides a capping tube forming method, the method specifically includes the following steps:

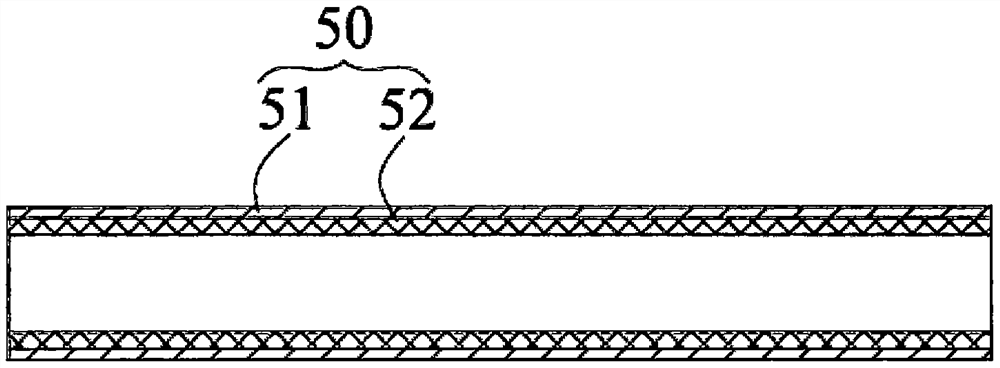

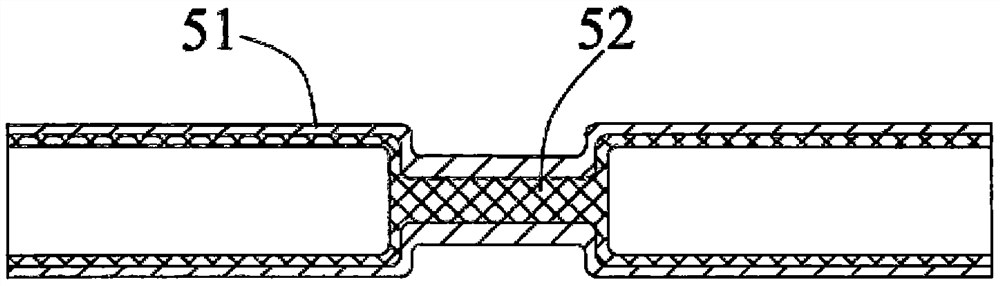

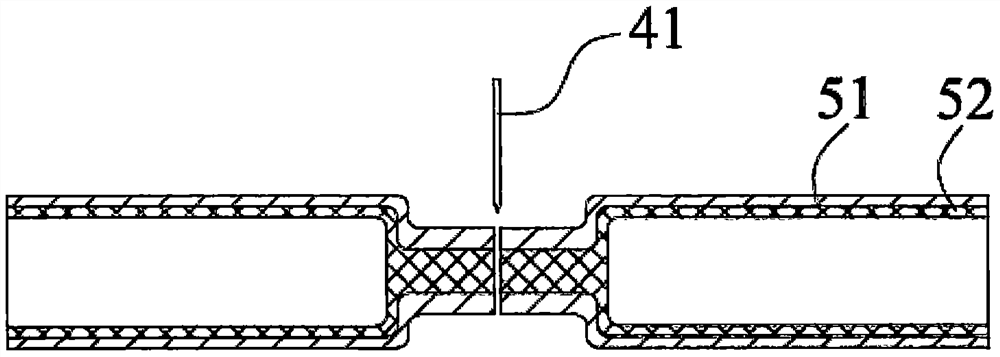

[0029] In the heating step, at least one heat-shrinkable double-walled tube 50 is taken, and the non-end position of the heat-shrinkable double-walled tube 50 is heated, the outer layer of the heat-shrinkable double-walled tube 50 shrinks and the inner layer of the hot melt adhesive layer 52 are melt-bonded together to form a closed section;

[0030] In the cutting step, the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com