Two-dimensional joint layout design method of packaging shell leads

A technology of encapsulation and design method, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of poor product consistency, difficulty in meeting the needs of mass production of products, low production efficiency, etc. The effect of appearance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

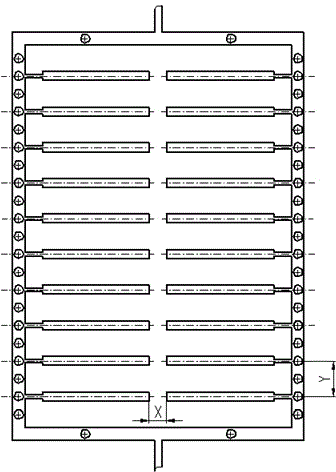

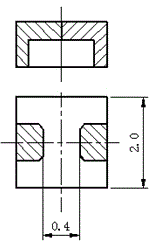

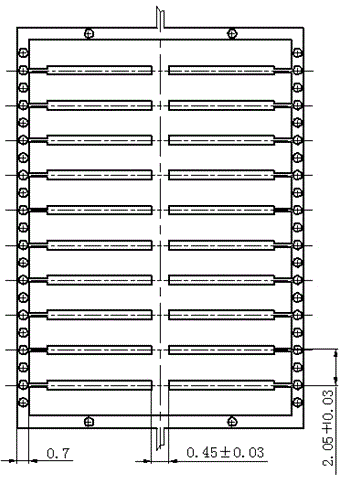

[0015] A certain ceramic component product A, its shape structure and size are as follows figure 2 As shown, its external dimensions include the spacing between the leads X1, the width of the porcelain part Y1,

[0016] (1) The spacing X1 of the metallization pattern corresponding to the lead assembly area of ceramic component product A is 0.4mm, the matching tolerance x' is ±0.03mm, and the spacing X=0.37mm~0.43mm is designed for the top of a single set of leads;

[0017] (2) The length dimension of ceramic component product A perpendicular to the lead wire direction is Y1=2.0mm, the fit tolerance y' is ±0.03mm, and the interval between each group of lead wires in the design row lead wire is Y=1.97mm~2.03mm;

[0018] (3) At the end of the lead, set a connecting rib with a width, through which the lead is connected in a matrix form, according to the spacing X=0.37mm~0.43mm at the top of a single group of leads and the interval between each group of leads Y= 1.97mm~2.03mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com