Glaze spraying process of robot glaze spraying circulation line and ceramic closestool prepared by glaze spraying process

A robot and circulation line technology, applied in the field of ceramic processing, can solve the problems of slow drying speed of glaze slurry, low utilization rate of glaze slurry, laminar flow glaze of green body glaze, etc., and achieve high production efficiency, low production labor cost, and defects low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

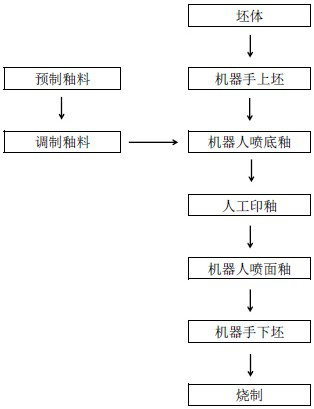

[0091] A glaze spraying process of a robot glaze spray circulation line, the robot spray glaze circulation line includes a robot spray glaze line; the robot spray glaze line is provided with a plurality of robots, and is also equipped with a ball mill and a disperser; the robot spray glaze The glaze spraying process of the glaze circulation line includes a prefabricated glaze step, a glaze modulation step and a robotic glaze spraying step; the specific gravity of the glaze modulated by the glaze modulation step is ≤1.800g / cm3, and the fluidity index is ≤200. Afterwards, the unglazed slurry flows from the green body;

[0092] Described prefabricated glaze step, comprises the following steps:

[0093] S1) Dispensing ingredients according to the set raw material composition;

[0094] S2) Put it into the ball mill, add water-reducing agent and grind to make glaze slurry;

[0095] S3) Detecting that the specific gravity, fluidity and fineness of the glaze slurry are all qualified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidity index | aaaaa | aaaaa |

| liquidity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com