Battery core shaping mechanism and fully-automatic battery core liquid-extracting, packaging and shaping packing machine

The invention relates to a battery cell and sealing technology, which is applied in the field of an automatic battery cell suction, sealing, forming and packaging machine and its battery cell shaping mechanism. Achieve the effect of preventing breakage, high appearance consistency, and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

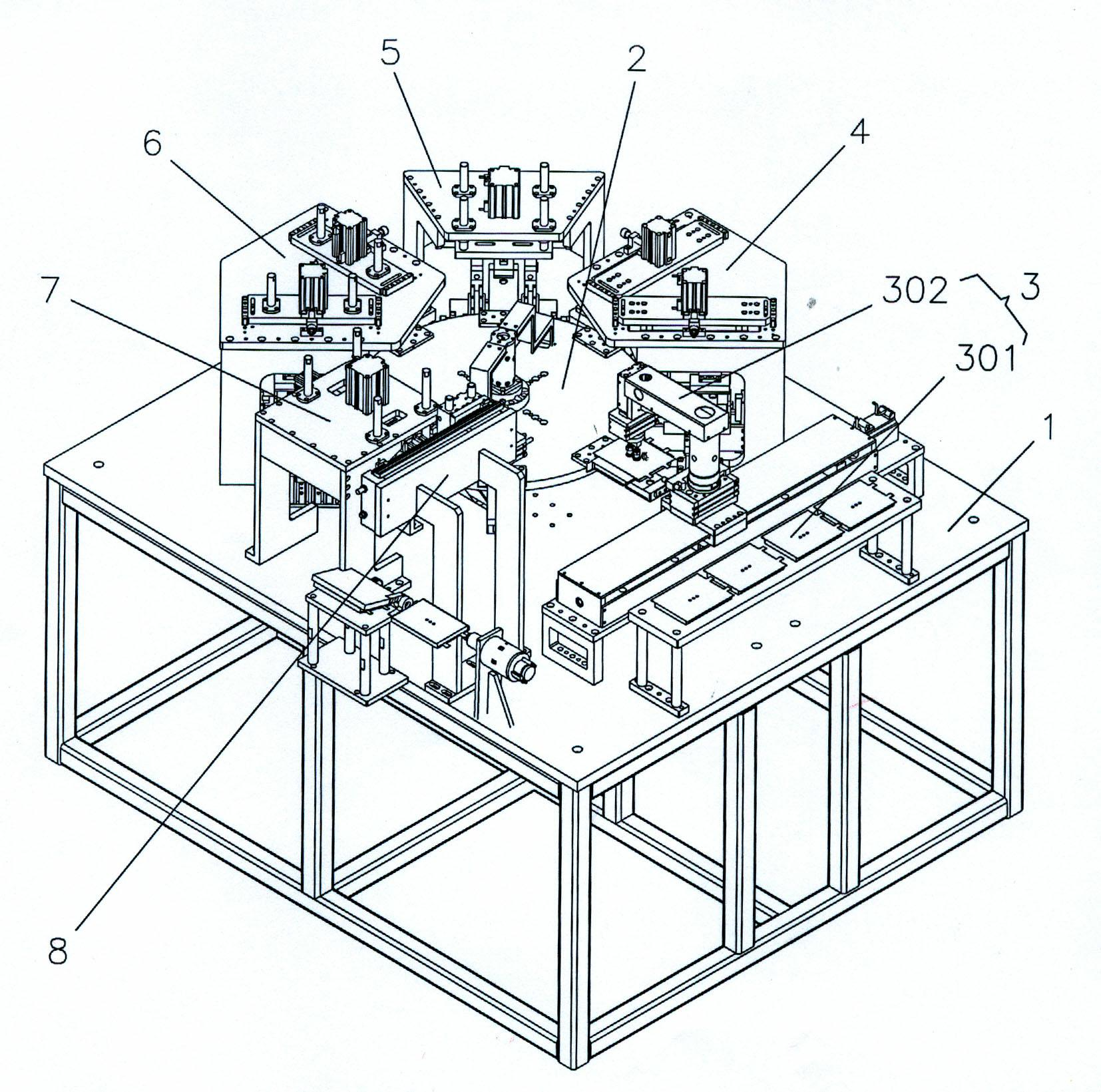

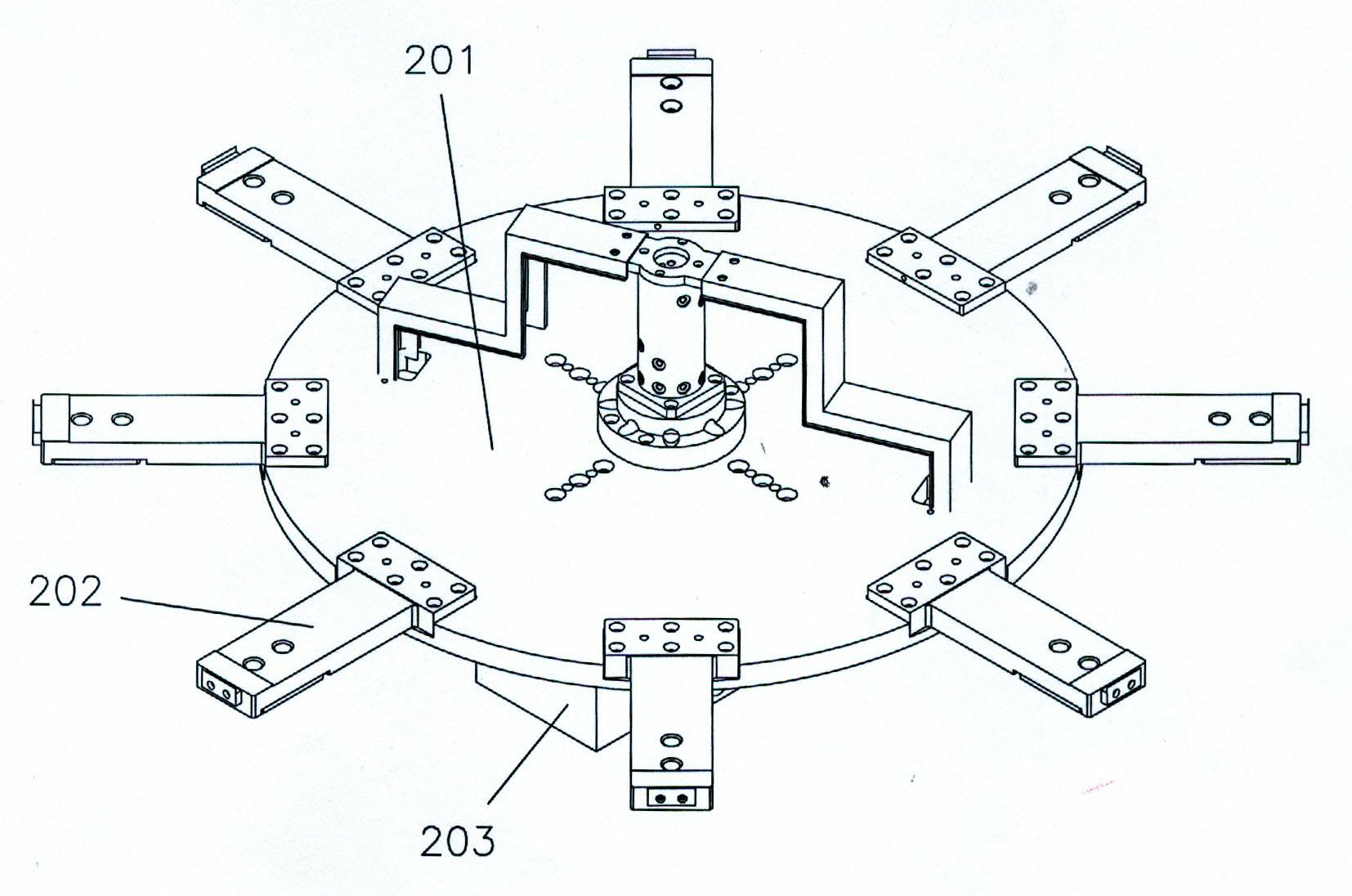

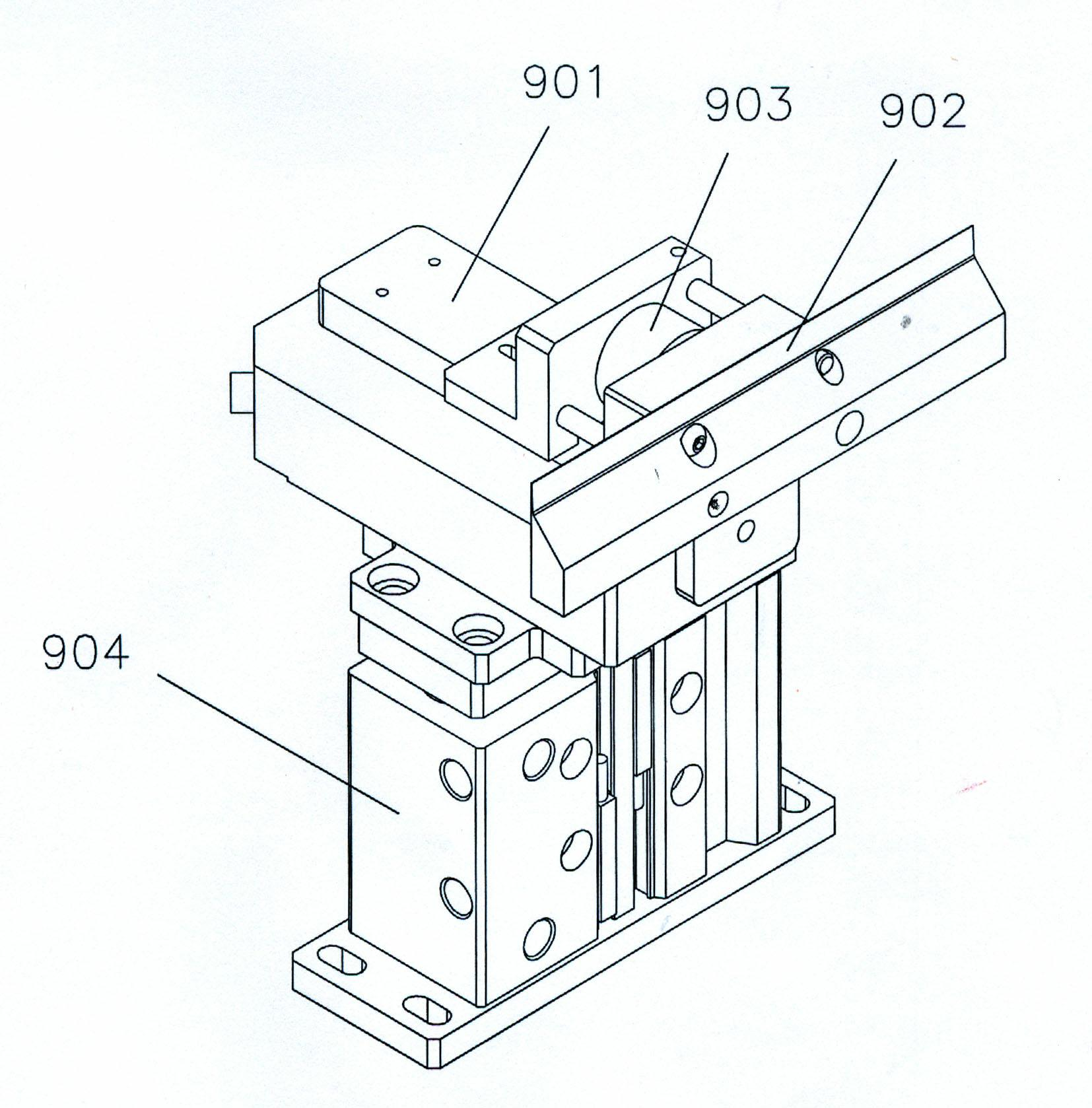

[0016] refer to figure 1 , a fully automatic battery pumping liquid sealing forming packaging machine, including a battery packaging mechanism and a battery shaping mechanism; the battery shaping mechanism includes a base 1, and a turntable device 2 for transmission is fixed on the base 1. 1. The outer edge of the upper edge of the turntable device 2 is sequentially fixed with a feeding device 3, an edge trimming device 4, a preheating device 5, an edge folding device 6, an edge ironing device 7 and a material unloading device 8; The core packaging mechanism completes the liquid pumping and packaging, and then is positioned by the feeding device 3 of the cell shaping mechanism and placed into the turntable device 2, driven by the turntable device 2 to enter the trimming device 4, preheating device 5, hemming device 6 and ironing device in sequence. The edge device 7 performs edge trimming, preheating before edge folding, edge folding and edge ironing, and then is sent out by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com