Filling method of damping layers of wheel noise reduction block, positioning structure and wheel noise reduction block

A technology of filling method and positioning structure, which is applied to the direction of wheels, wheels characterized by rail running parts, vehicle parts, etc., which can solve the problems of easy deformation of constraining layer and mounting plate, uneven rubber thickness, etc., and avoid welding deformation. , Reduce process difficulty and manufacturing cost, and ensure the effect of manufacturing quality and dimensional deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

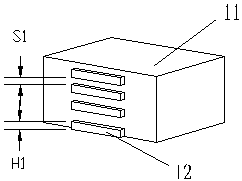

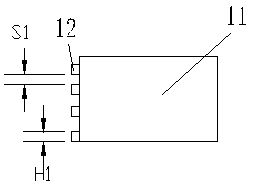

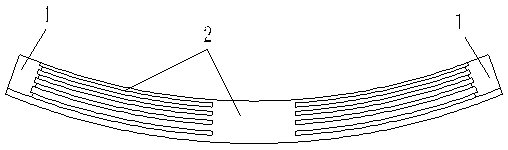

[0059] Such as Figure 3-Figure 6 As shown, the wheel noise reduction block includes a sandwich structure 2 and a damping layer 3. The sandwich structure 2 includes a strip-shaped constraining layer 22, an intermediate body 24 and a mounting plate 21. The sandwich structure 2 is an integrally cast rigid layer, and the constraining layer 22 and the mounting plate 21 are connected as a whole through the intermediate body 24 in the middle, there is a gap layer 23 at both ends of each two layers of the sandwich structure 2, and the damping layer 3 is arranged in the gap layer 23 of the sandwich structure 2, and the sandwich structure 2 vulcanization bonding and fixing, the end face and / or side of the damping layer 3 has a positioning groove 31.

[0060] In order to solve the problem of metal deformation during the welding process of the constraining layer 22 and the mounting plate 21, and the manufacturing process of the sandwich structure 2 is complex, difficult, poor in consiste...

Embodiment 2

[0068] The basic method and principle of this embodiment are the same as those of the above embodiment, the difference is that: Figure 7As shown, the intermediate of the sandwich structure 2 is a gasket 27, the constraining layer 22 and the gasket 27 are one piece or a plurality of equal numbers, the mounting plate 21 is located at the lowest end, and the gasket 27 and the constraining layer 22 are alternately arranged on the mounting plate Above, the gasket 27 of the lowest layer is in contact with the mounting plate 21, the length of the gasket 27 is less than the length of the constraining layer 22, the mounting plate 21, the constraining layer 22 and the gasket 27 are integrally connected by rigidity, the constraining layer 22 and the mounting plate 21 or between the constraining layer 22 and the mounting plate 21 and between the constraining layer 22 and the constraining layer 22, there is a gap layer 23 with an equal distance, and in the middle of the integrally formed m...

Embodiment 3

[0071] The basic method and principle of this embodiment are the same as those of the above embodiment, the difference is that: Figure 8 As shown, the sandwich structure 2 includes a mounting plate 21 and a first outer constraining layer 221, the intermediate body is a mandrel 28, a suspended inner constraining layer 222 arranged between the mounting plate 21 and the first outer constraining layer 221, and a hollow core The shaft 28 passes through the suspended inner constrained layer 222 and one end of the mandrel 28 is in contact with the mounting plate 21, the other end of the mandrel 28 is in contact with the first outer constrained layer 221, and the suspended inner constrained layer 222 is vulcanized and glued by the damping layer 3. Connected between the mounting plate 21 and the first outer constraining layer 221, wherein the mandrel 28 is one, the middle position of the sandwich structure 2 is set, the middle position of the sandwich structure 2 has a mounting hole 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com