Honeycomb structure

A honeycomb structure and honeycomb technology, applied in gas chambers, gas channels, gas treatment, etc., can solve problems such as reduction, crack bonding strength, and joint damage, and achieve the effect of not being easily damaged and maintaining bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

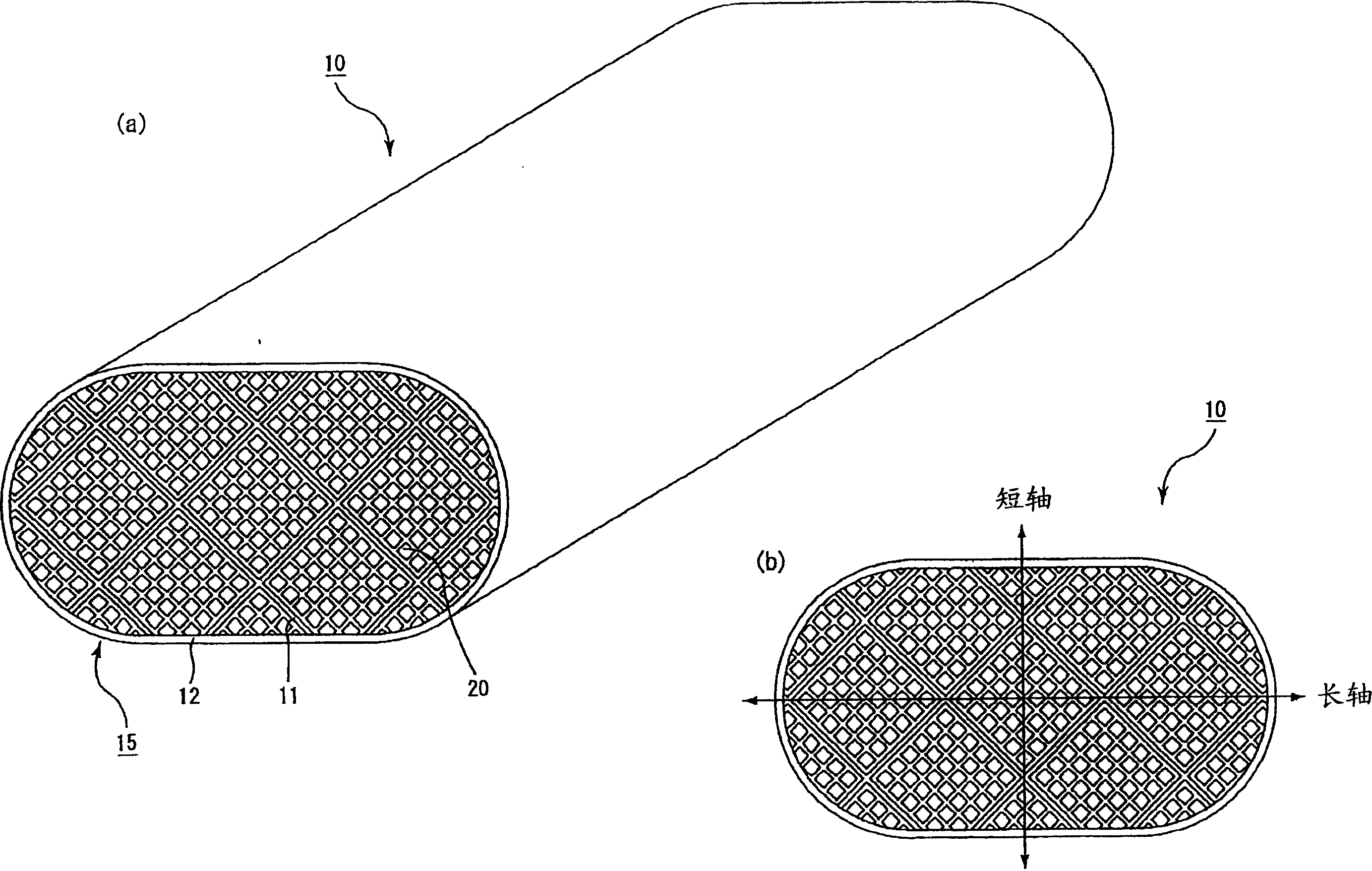

Embodiment 1

[0138] Mix 40% by weight of γ-alumina particles (average particle diameter 2 μm), 10% by weight of silica-alumina fibers (average fiber diameter 10 μm, average fiber length 100 μm, aspect ratio 10) and 50% by weight of silica sol (solid concentration: 30% by weight), with respect to 100 parts by weight of the obtained mixture, after adding 6 parts by weight of methylcellulose, a small amount of plasticizer and a small amount of lubricant as an organic binder, they were mixed and kneaded to obtain a mixed composition .

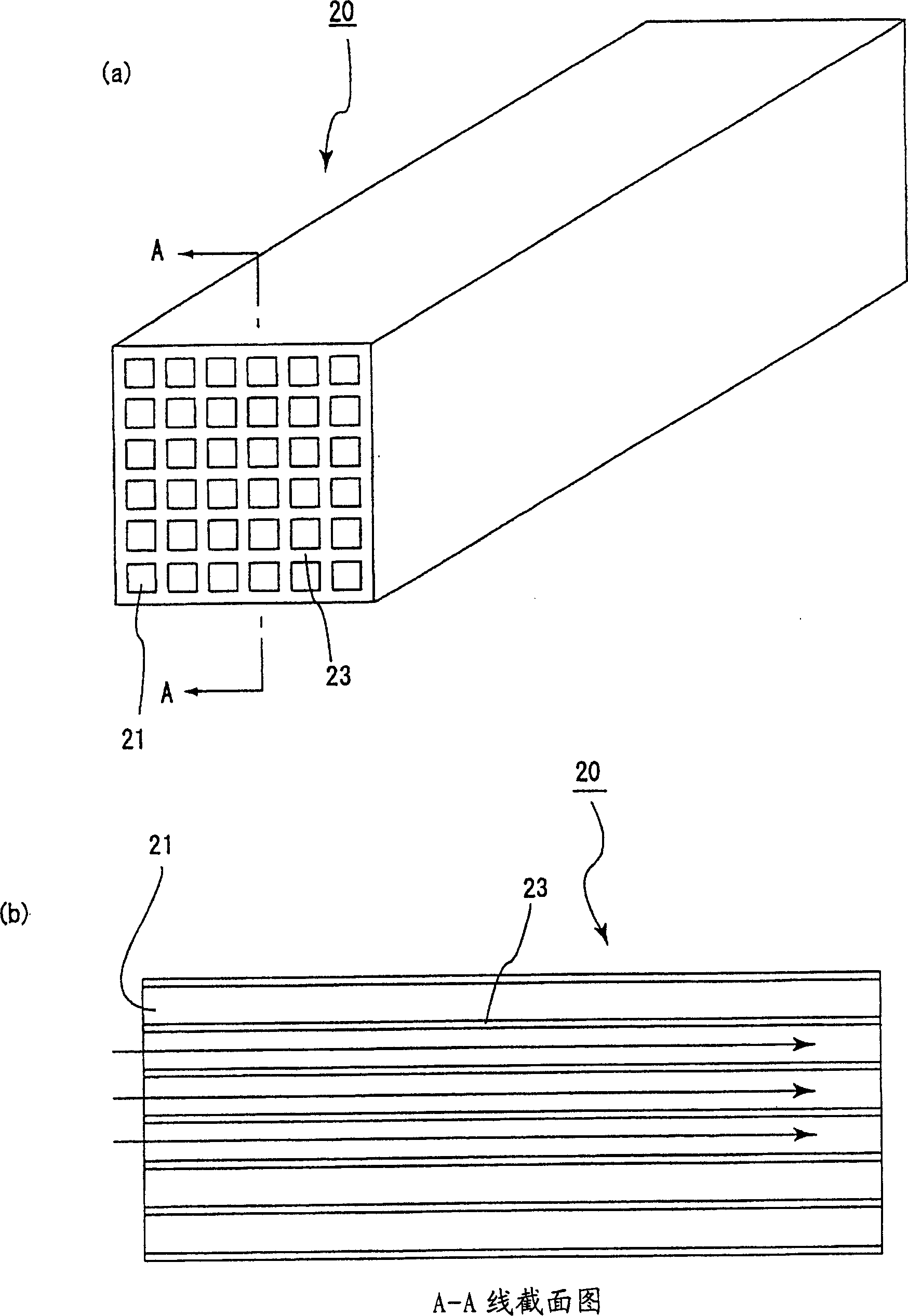

[0139] Then use the mixed composition to carry out extrusion molding to make the shape of the end face and figure 2 (a) A rough molded body having substantially the same end surface shape.

[0140] Next, dry the rough molded body with a microwave dryer to make a ceramic dry body, then degrease at 400°C for 2 hours, and then fire at 800°C for 2 hours to manufacture the honeycomb unit 20. The specific surface area is 42000m 2 / L, the size is 34.3mm×34.3mm×150...

Embodiment 2~7

[0150] (Examples 2-7, Comparative Examples 1-3)

[0151] On the section perpendicular to the length direction, the angle formed by the sealing material layer (adhesive layer) between the honeycomb units and the major axis of the shape that constitutes the cross-sectional profile, and the value of the maximum cross-sectional area of the honeycomb unit perpendicular to the length direction is as follows: Except as shown in Table 1, the honeycomb structure 10 was produced in the same manner as in Example 1.

Embodiment 8~14、 comparative example 4~6

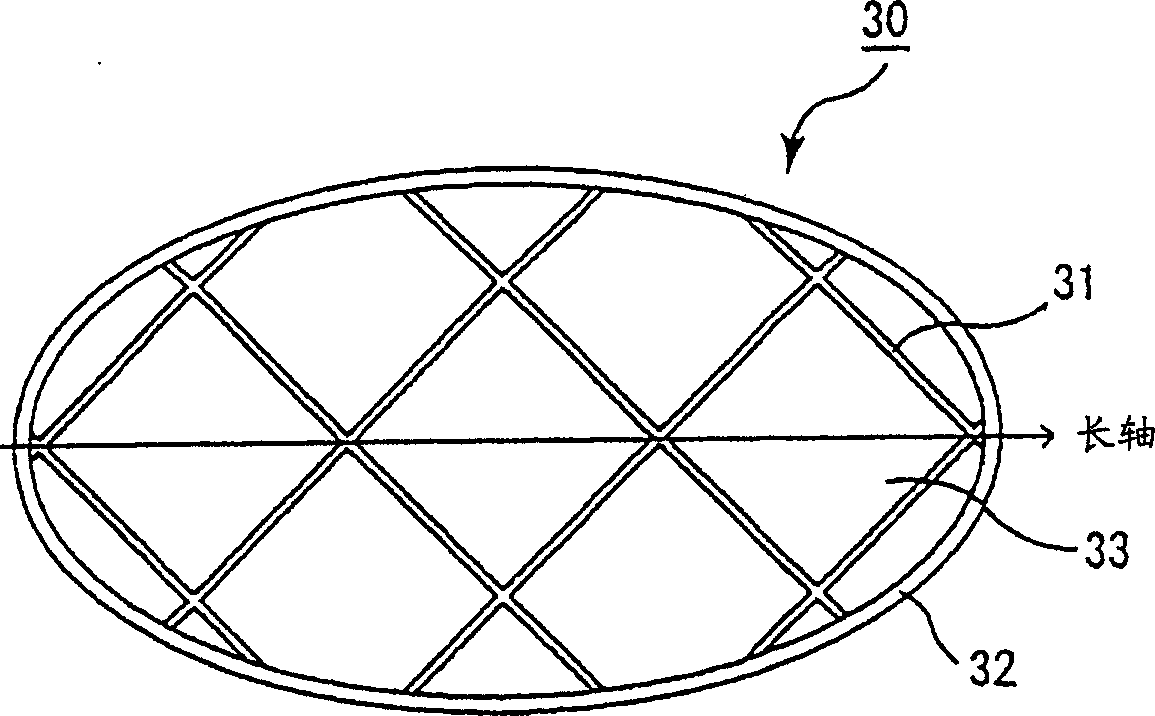

[0153] Set the end face profile to image 3 The ellipse shown, and the angle formed by the sealing material layer (adhesive layer) between the honeycomb units and the major axis of the shape constituting the cross-sectional profile on a section perpendicular to the length direction, and the honeycomb unit perpendicular to the length direction The value of the maximum cross-sectional area is shown in Table 1, and the honeycomb structure 30 was produced in the same manner as in Example 1 except that.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com