Power cable sheath tube with high insulativity

A power cable, high insulation technology, applied in the field of sheath tube production, can solve the problems of loss of efficacy, corrosion resistance, etc., to achieve the effect of enhancing oxidation resistance, increasing high insulation, high strength and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

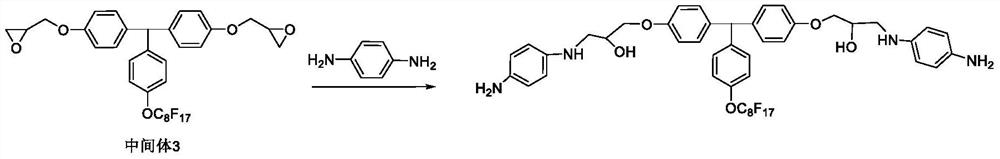

[0027] Anti-corrosion additives are made through the following steps:

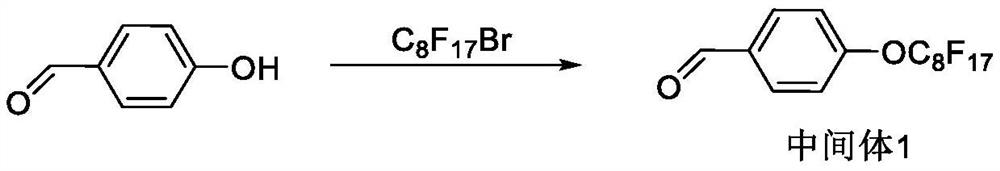

[0028] Step A. Dissolve 0.02mol 4-hydroxybenzaldehyde in 10mL dimethyl sulfoxide, then add 0.02mol potassium carbonate and 0.1g potassium iodide, raise the temperature to 112°C, add 0.02mol 1-bromoperfluoroheptane dropwise, drop The acceleration is 1 drop / second, react for 8 hours, cool down, pour the reaction mixture into a large amount of deionized water, and place it at 5°C for 30 minutes, a large amount of white precipitate is produced, filter, wash with deionized water repeatedly for 3 times, dry to constant weight, and obtain intermediate Body 1;

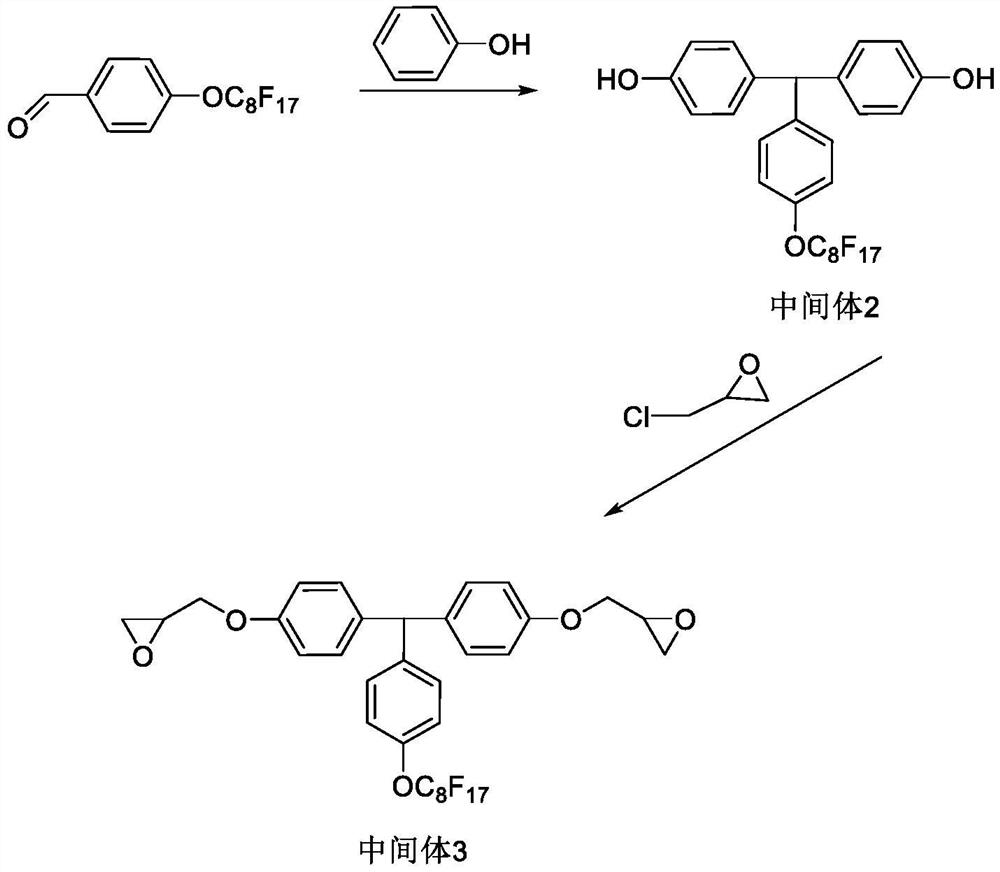

[0029] Step B. Add 0.03mol of intermediate 1, 0.06mol of phenol and 15mL of glacial acetic acid into a three-neck flask equipped with a condensing reflux tube and a stirring magnet, and add concentrated sulfuric acid and ice with a constant pressure dropping funnel under stirring at 0°C. Mixture of acetic acid was 40mL, the rate of addition was 1 drop / sec...

Embodiment 2

[0032] Anti-corrosion additives are made through the following steps:

[0033] Step A. Dissolve 0.02mol of 4-hydroxybenzaldehyde in 30mL of dimethyl sulfoxide, then add 0.02mol of potassium carbonate and 0.1-0.2g of potassium iodide, raise the temperature to 112°C, and add dropwise 0.022mol of 1-bromoperfluoroheptane , the dropping rate is 1 drop / second, react for 8 hours, cool the reaction mixture into a large amount of deionized water, place it at 5°C for 30 minutes, a large amount of white precipitate is produced, filter, wash with deionized water repeatedly for 3 times, dry to constant weight, Intermediate 1 is obtained;

[0034]Step B. Add 0.03mol of intermediate 1, 0.06mol of phenol and 30mL of glacial acetic acid into a three-neck flask equipped with a condensing reflux tube and a stirring magnet, and add concentrated sulfuric acid and ice with a constant pressure dropping funnel under stirring at 2°C. The mixed solution of acetic acid was 50mL, and the dropping rate w...

Embodiment 3

[0037] A power cable sheathing tube with high insulation, comprising the following raw materials in parts by weight: 90 parts of polypropylene, 8 parts of calcium carbonate, 3 parts of glass fiber, 5 parts of talcum powder, 1 part of carbon black, and 0.5 parts of coupling agent , 0.3 parts of antioxidant, 0.3 part of lubricant, 1.5 parts of anti-corrosion additive prepared in embodiment 1, wherein, the coupling agent is a titanate coupling agent; the antioxidant is antioxidant 1010, antioxidant The oxidizing agent 168 is mixed according to the mass ratio of 1:3, and the lubricant is stearic acid.

[0038] This kind of high insulation power cable sheath is made through the following steps:

[0039] Step 1, coupling agent and acetone are made into coupling agent solution, then coupling agent solution and calcium carbonate, glass fiber, talcum powder, carbon black are mixed and stirred for 10min, then transferred to a vacuum drying oven for drying, and solvent is removed to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com