Preparation method and device of special membrane material for mining air drum

A film material and air duct technology is applied in the field of preparation of special film materials for mining air ducts, which can solve the problems of non-compliance with energy saving and emission reduction, consuming a large amount of heat energy, wasting time, etc., to save heat and labor, save energy and save time cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

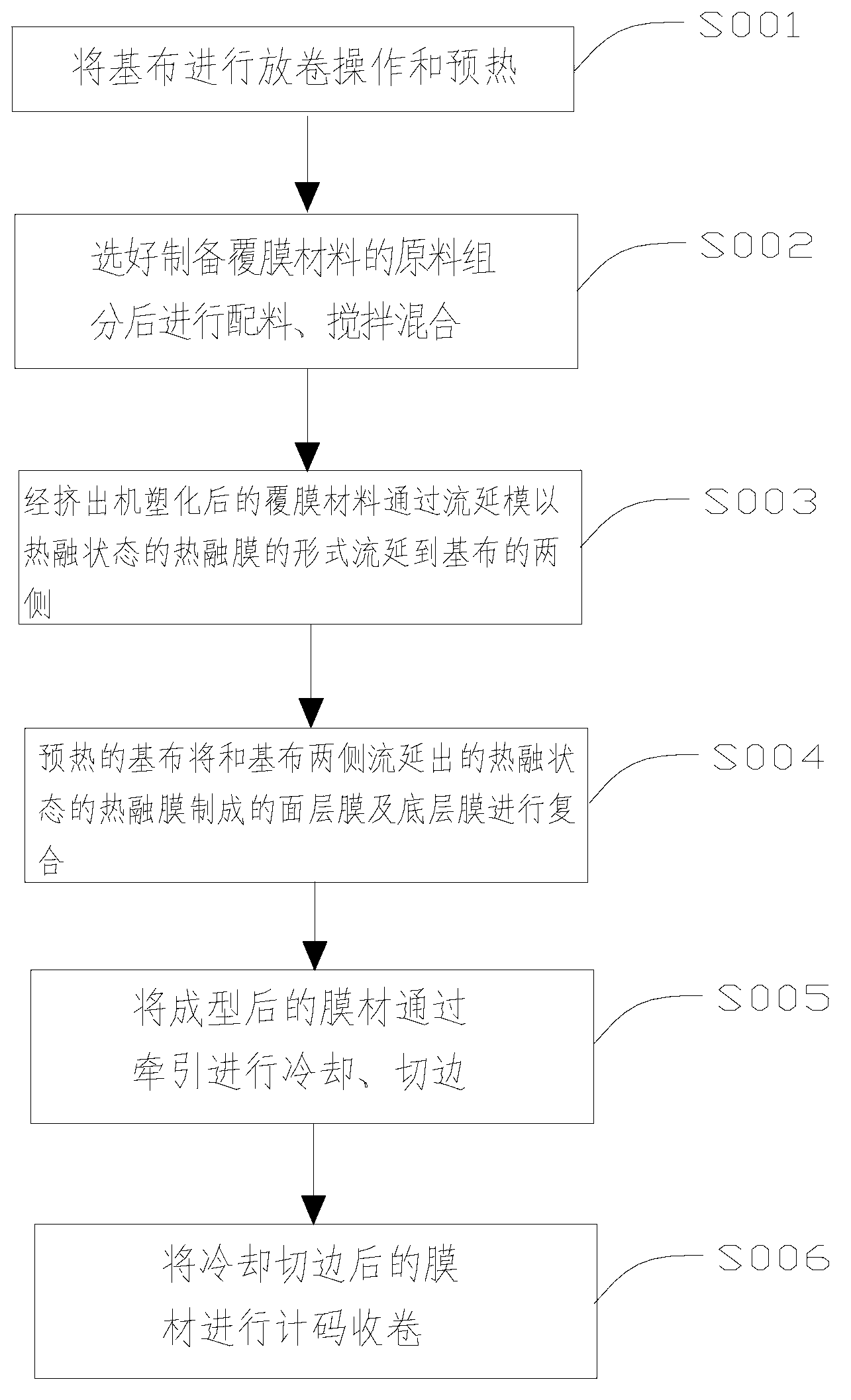

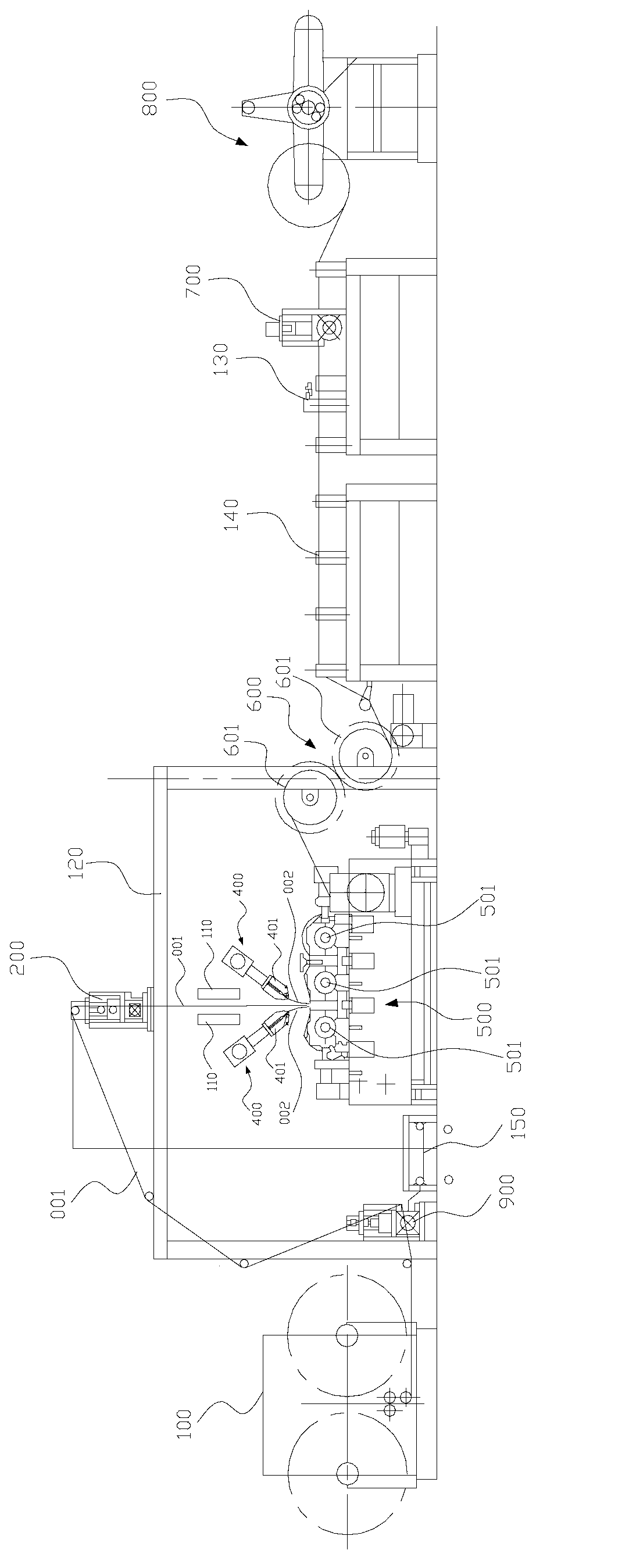

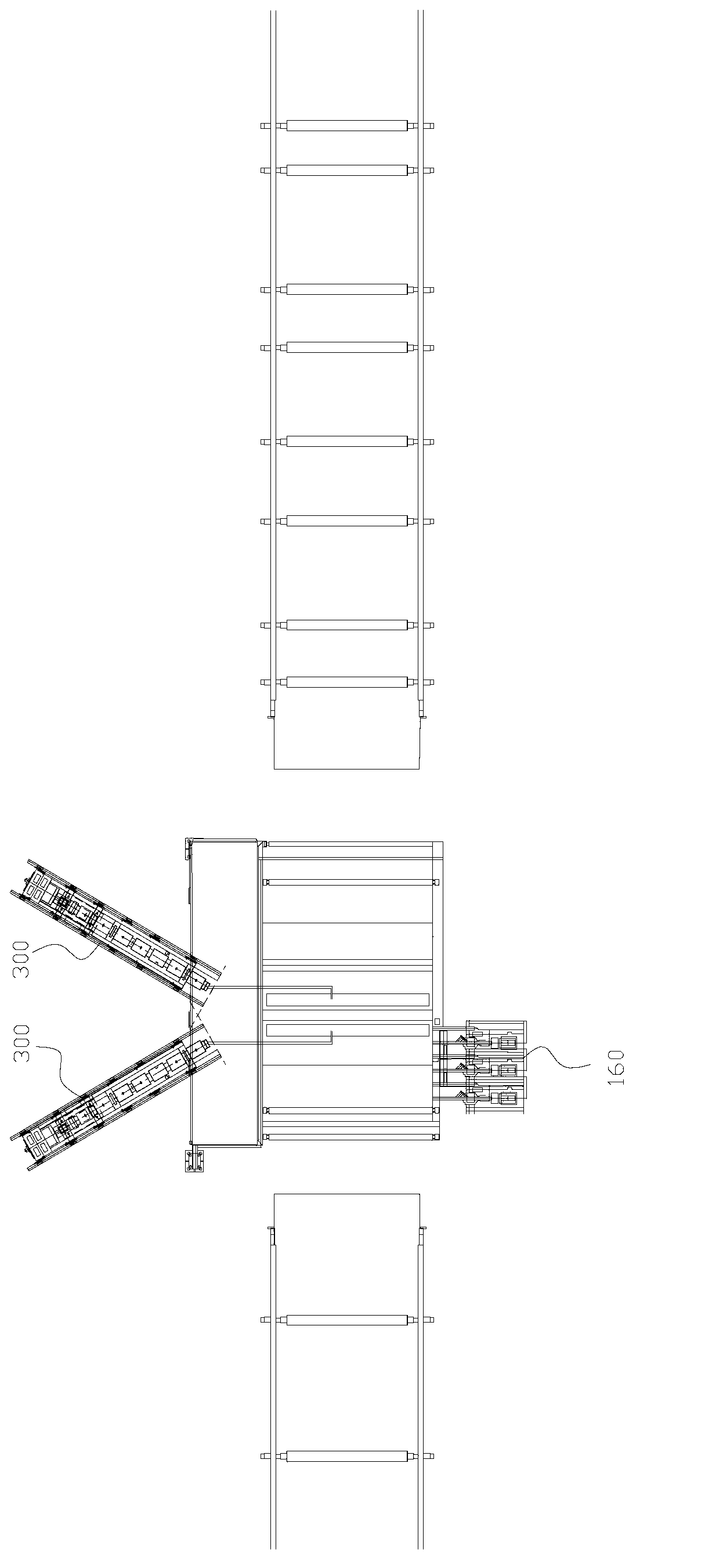

[0042] Below in conjunction with accompanying drawing, invention is described in further detail.

[0043] Such as figure 1 As shown, this embodiment provides a method for preparing a special membrane material for mine air ducts. The method includes the following steps: unwinding and preheating the base cloth (step S001). In this embodiment, the base cloth is selected from 1100 ×1100 dtex, 20×20 / inch, L1:1 woven base fabric, when unwinding, care should be taken to control the longitudinal and transverse tension of the base fabric to be uniform, stable and flat. The base fabric can be made of polyester fiber fabric, and it is best to preheat the base fabric during the process of unwinding the base fabric, and the temperature range of the base fabric preheating is 105-115 degrees Celsius.

[0044] After selecting the raw material components of the coating material, carry out batching, stirring and mixing (step S002), wherein the raw material components of the coating material in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com