High-performance and low-cost titanium alloy

A titanium alloy, low-cost technology, applied in the field of titanium alloys, can solve the problems of limited quantity and types of titanium alloy residues, ineffective cost reduction effect, unfavorable performance of titanium alloys, etc., to achieve large-scale utilization and remelting Effect of mass consistency, resolution of compositional segregation and tissue inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

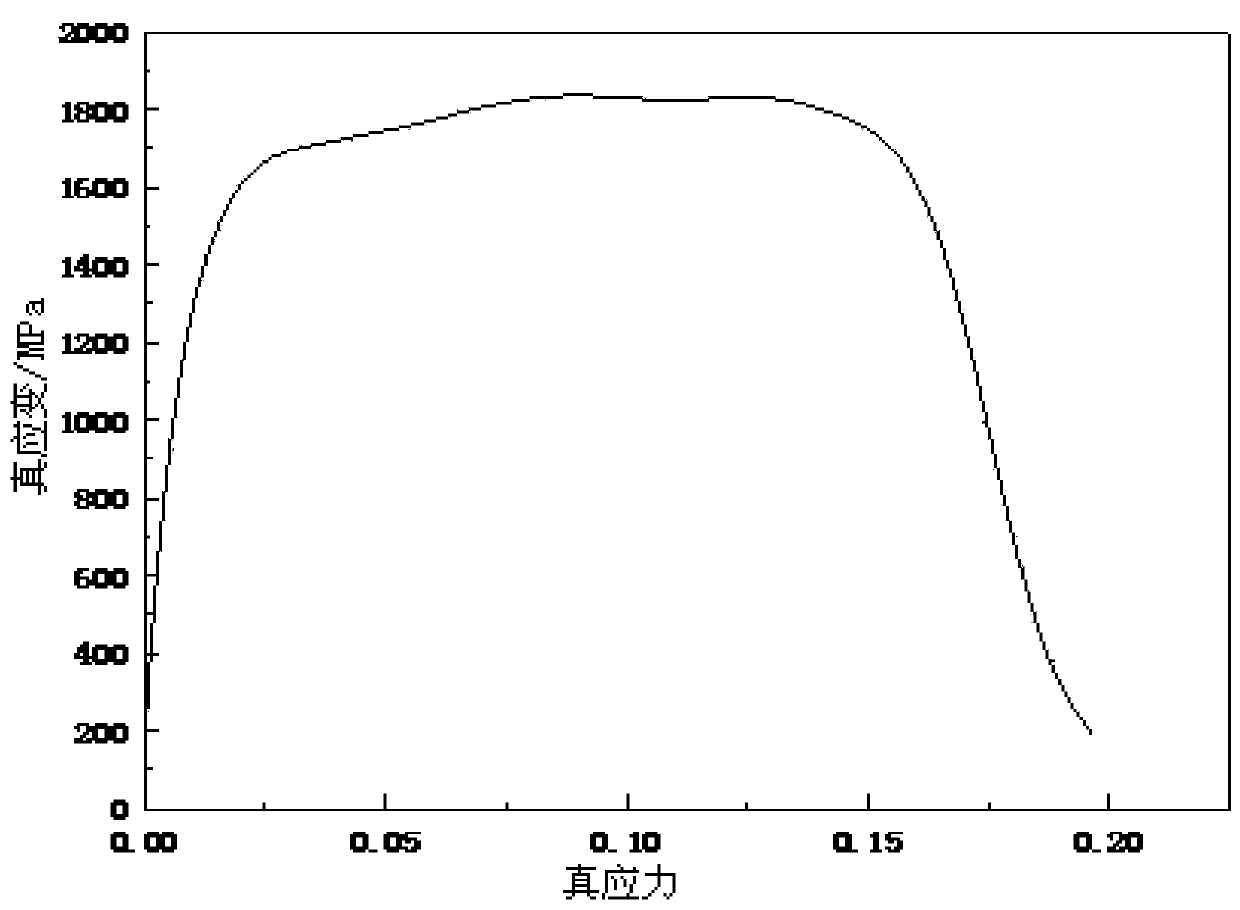

Image

Examples

Embodiment 1

[0021] The titanium alloy of the present embodiment is made up of the composition of following mass percentage content: Al 4.0%, V 3.0%, Mo2.6%, Fe 1.6%, the balance is Ti and unavoidable impurity, and the preparation method of this titanium alloy comprises The following steps:

[0022] Step 1. Select grade 1 sponge titanium, iron-molybdenum alloy (the mass content of molybdenum in the iron-molybdenum alloy is 61.9%), aluminum beans and TC4 recycled materials after degreasing and decontamination treatment as raw materials for preparation;

[0023] Step 2. Proportioning the raw materials selected in step 1 according to the design composition of the titanium alloy Ti-4.3Al-3.0V-2.6Mo-1.6Fe, and proportioning according to the quality of the titanium alloy flat ingot is 300kg. 224.5kg of TC4 reclaimed material after pollution treatment, 62.4kg of grade 1 sponge titanium, 12.6kg of iron-molybdenum alloy, and 0.5kg of aluminum beans, and then smelted once in an electron beam cooling...

Embodiment 2

[0029] The titanium alloy of this embodiment is made up of the composition of following mass percent: Al 6.6%, V 2.0%, Mo3.2%, Fe 2.1%, the balance is Ti and unavoidable impurity, and the preparation method of this titanium alloy comprises The following steps:

[0030] Step 1, select grade 1 sponge titanium, iron-molybdenum alloy (the mass content of molybdenum in the iron-molybdenum alloy is 60.4%), aluminum beans and TC4 recycled materials after degreasing and decontamination treatment as raw materials for preparation;

[0031] Step 2. Proportioning the raw materials selected in step 1 according to the design composition of the titanium alloy Ti-6.6Al-2.0V-3.2Mo-2.1Fe, and proportioning according to the quality of the titanium alloy flat ingot is 300kg. 150kg of TC4 reclaimed material after pollution treatment, 123.3kg of grade 1 sponge titanium, 11.4kg of aluminum beans, 15.9kg of iron-molybdenum alloy, and then smelted once in an electron beam cooling bed furnace to obtain...

Embodiment 3

[0036] The titanium alloy of the present embodiment is made up of the composition of following mass percent: Al 5.5%, V 2.5%, Mo3.0%, Fe 1.9%, the balance is Ti and unavoidable impurity, and the preparation method of this titanium alloy comprises The following steps:

[0037] Step 1. Select grade 1 sponge titanium, iron-molybdenum alloy (the mass content of molybdenum in the iron-molybdenum alloy is 61.2%), aluminum beans and TC4 reclaimed material after degreasing and decontamination treatment as raw materials for preparation;

[0038] Step 2. Proportioning the raw materials selected in step 1 according to the design composition of the titanium alloy Ti-5.5Al-2.5V-3.0Mo-3.5Fe, and proportioning according to the quality of the titanium alloy flat ingot is 300kg. 187.5kg of TC4 reclaimed material after pollution treatment, 92.55kg of grade 1 sponge titanium, 5.85kg of aluminum beans, 14.7kg of iron-molybdenum alloy, and then smelted once in an electron beam cooling bed furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com