Low-cost short-process manufacture technique for high-strength rare earth magnesium alloy plate

An alloy sheet, short process technology, applied in the field of metal material processing, can solve the problems of high alloy cost, complex and time-consuming preparation process, shortened preparation process, etc., and achieve the effects of reducing rare earth content, shortening process flow, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

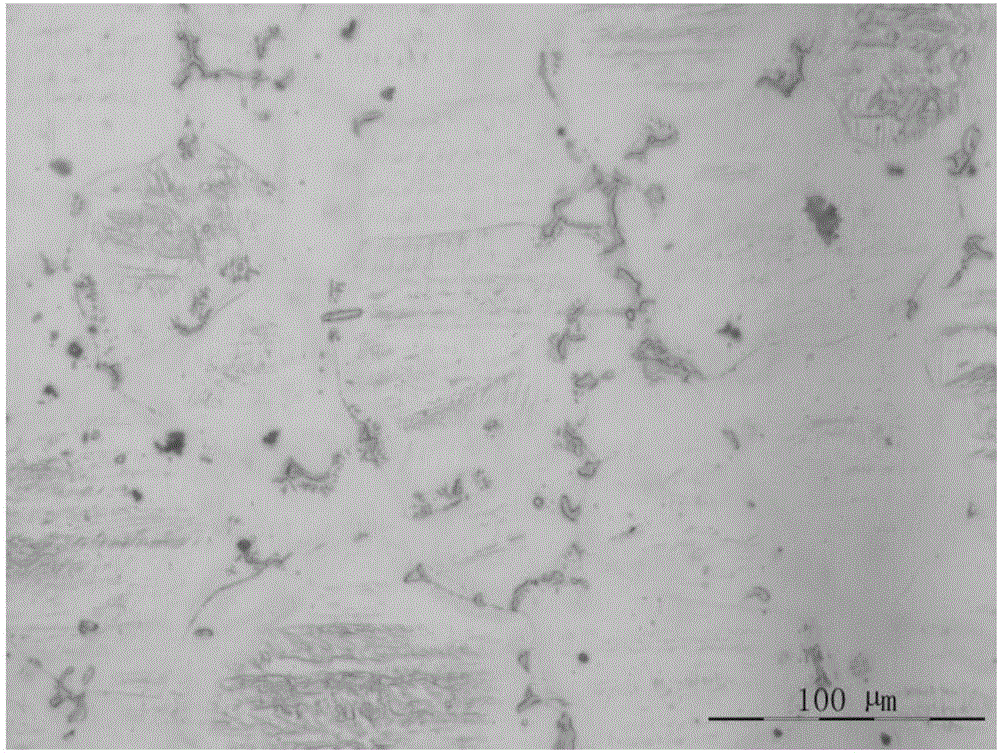

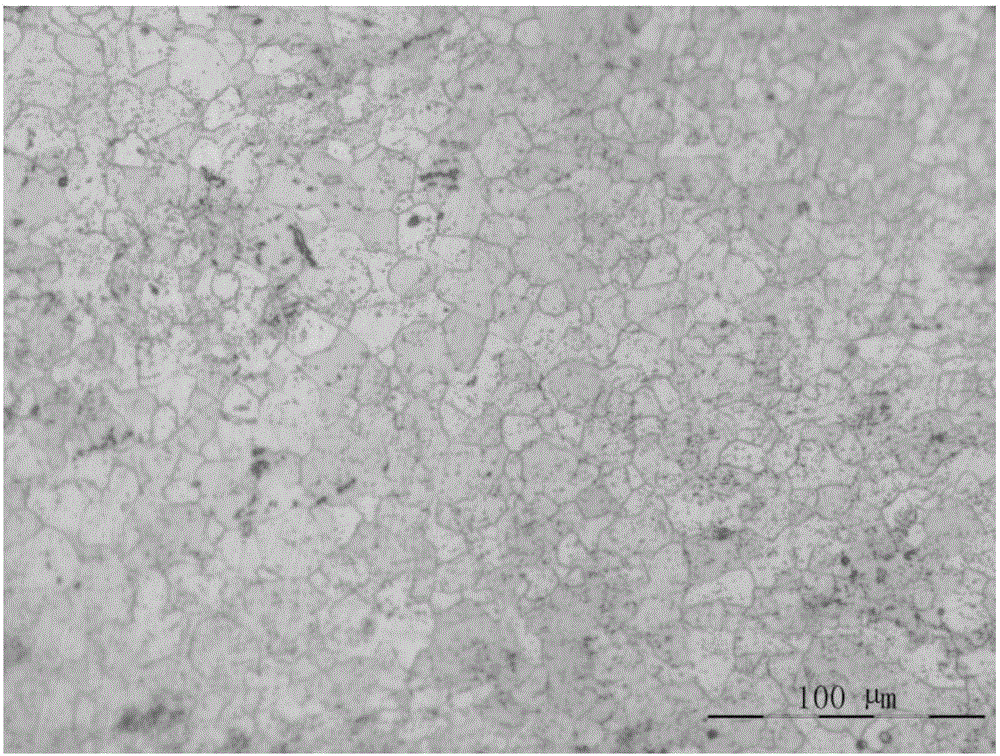

[0017] Example 1: Put the as-cast alloy into a heat treatment furnace at 300°C for 15 minutes, the alloy composition is Gd: 2.0wt.%, Er: 0.1wt.%, Zr: 0.5wt.%, and Mg is the balance balance; Take out and place on twin-roll rolling equipment for rolling, the thickness of the alloy billet is 5mm, and the thickness after rolling is 0.25mm to obtain a total deformation of 95%, Mg 5 (Gd, Er) strengthening phase size is 200nm, Mg 5 A high-strength magnesium alloy plate with a volume fraction of (Gd, Er) strengthening phase of 1.8%, a grain size of 9 μm, a yield strength of 280 MPa, and a tensile strength of 310 MPa.

Embodiment 2

[0018] Example 2: Put the as-cast alloy into a heat treatment furnace at 550°C for 15 minutes, and the alloy composition is Gd: 6.2wt.%, Er: 0.15wt.%, Zr: 0.5wt.%, and Mg is the balance balance; Take out and place on twin-roll rolling equipment for rolling, the thickness of the alloy billet is 5mm, and the thickness after rolling is 0.75mm to obtain a total deformation of 85%, Mg 5 (Gd, Er) strengthening phase size is 260nm, Mg 5 A high-strength magnesium alloy plate with a volume fraction of (Gd, Er) strengthening phase of 5.6%, a grain size of 9 μm, a yield strength of 290 MPa, and a tensile strength of 322 MPa.

Embodiment 3

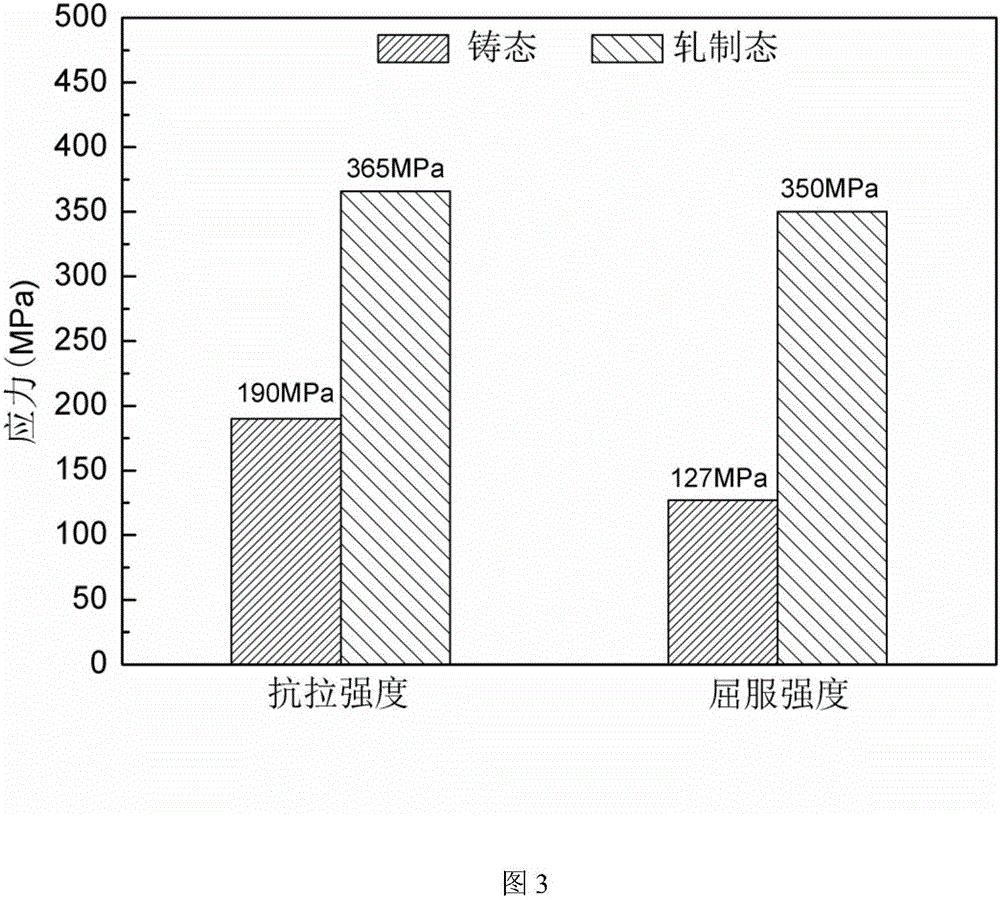

[0019] Example 3: Put the as-cast alloy into a heat treatment furnace at 400°C for 15 minutes, the alloy composition is Gd: 8.0wt.%, Er: 1.0wt.%, Zr: 0.5wt.%, and Mg is the balance balance; Take out and place on twin-roll rolling equipment for rolling, the thickness of the alloy billet is 5mm, and the thickness after rolling is 0.15mm to obtain a total deformation of 97%, Mg 5 (Gd, Er) strengthening phase size is 300nm, Mg 5 A high-strength magnesium alloy plate with a volume fraction of (Gd, Er) strengthening phase of 7.8%, a grain size of 7.5 μm, a yield strength of 350 MPa, and a tensile strength of 365 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com