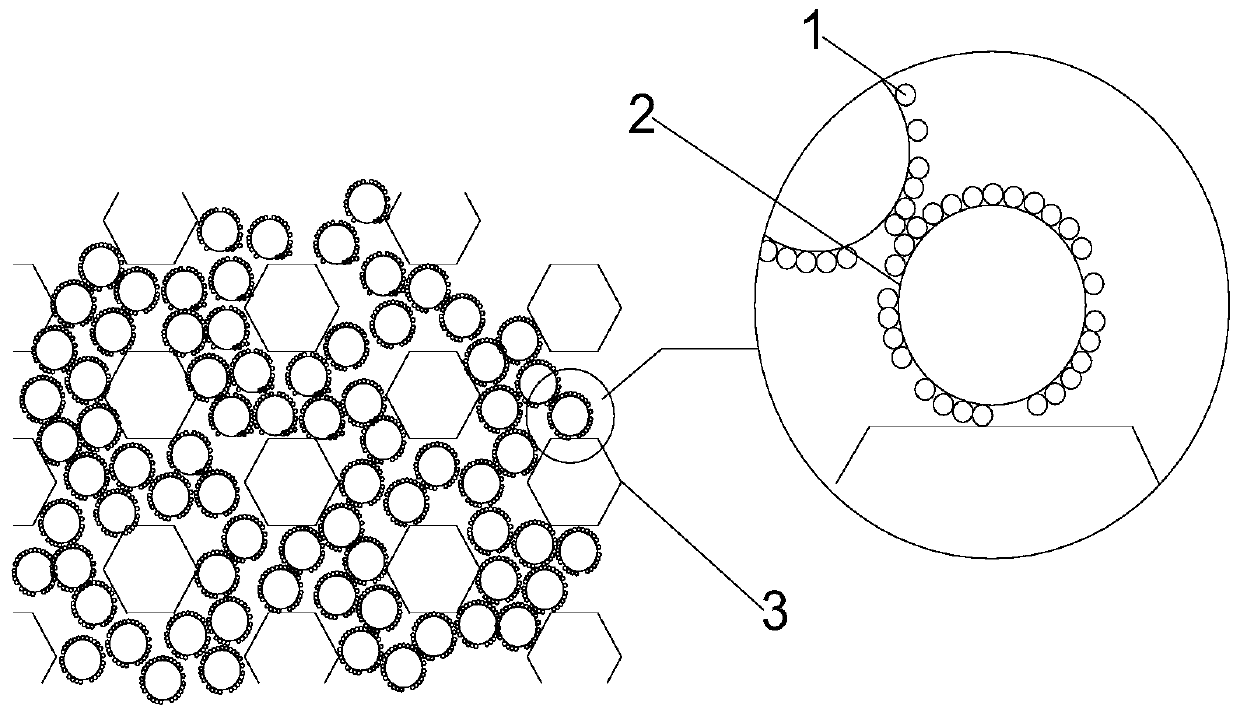

Nano-microbubble material for modifying pulverized coal in-situ consolidation and preparation method thereof

A nano-material, in-situ technology, applied in the field of coal consolidation materials and its preparation, can solve the problems of poor gas permeability of grouting materials, inability to solve problems such as borehole nozzle holes, difficult gas penetration, etc., so as to improve construction safety. performance, facilitate gas extraction, and improve compression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: First use the high-energy nano-impact mill equipment, add high-efficiency dispersant, utilize the existing dry grinding process to process the particles of Portland cement particles and speed control agents to nano-scale standby; Speed control agent Add a high-efficiency dispersant to the tank before grinding, with a mass of 0.2% of the mass of the material to be pulverized to prevent particle agglomeration during the pulverization process. Then in container A, add 0.5 parts of vegetable cement foaming agent in parts by weight, after mixing 30 parts of water and 0.2 part of polyurethane foam stabilizer, prepare the foaming liquid for future use. In the mixing vessel B, add 40 parts of nano-sized Portland cement particles and 0.8 parts of nano-sized speed control agent according to the parts by weight, and simultaneously add 60 parts of water, 1 part of water glass and 1 part of early strength agent; the stirring container B is sealed and the inside is un...

Embodiment 2

[0021] Embodiment 2: First use the high-energy nano-impact mill equipment, add high-efficiency dispersant, utilize the existing dry grinding process to process the particles of Portland cement particles and speed control agents to nano-scale standby; Speed control agent Add a high-efficiency dispersant to the tank before grinding, with a mass of 0.2% of the mass of the material to be pulverized to prevent particle agglomeration during the pulverization process. Then add 1 part of vegetable cement foaming agent in parts by weight, 60 parts of water and 0.2 part of polyurethane foam stabilizer in container A, and prepare the foaming liquid for future use. In the mixing vessel B, add 50 parts of nano-sized Portland cement particles and 0.9 parts of nano-sized speed control agent prepared according to parts by weight, and simultaneously add 90 parts of water, 1.5 parts of water glass and 1.3 parts of early strength agent; the stirring container B is sealed and the inside is unde...

Embodiment 3

[0022]Embodiment 3: First use the high-energy nano-impact mill equipment, add high-efficiency dispersant, utilize the existing dry grinding process to process the particles of Portland cement particles and speed control agents to nano-scale standby; Speed control agent Add a high-efficiency dispersant to the tank before grinding, with a mass of 0.2% of the mass of the material to be pulverized to prevent particle agglomeration during the pulverization process. Then add 1 part of vegetable cement foaming agent in parts by weight, 60 parts of water and 0.2 part of polyurethane foam stabilizer in container A, and prepare the foaming liquid for future use. In the mixing vessel B, add 60 parts of nano-sized Portland cement particles and 1.2 parts of nano-sized speed control agent according to parts by weight, and simultaneously add 120 parts of water, 2 parts of water glass and 1.4 parts of early strength agent; the stirring container B is sealed and the inside is under the condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com