Method for preparing high performance nickel powder using shearing and breaking process

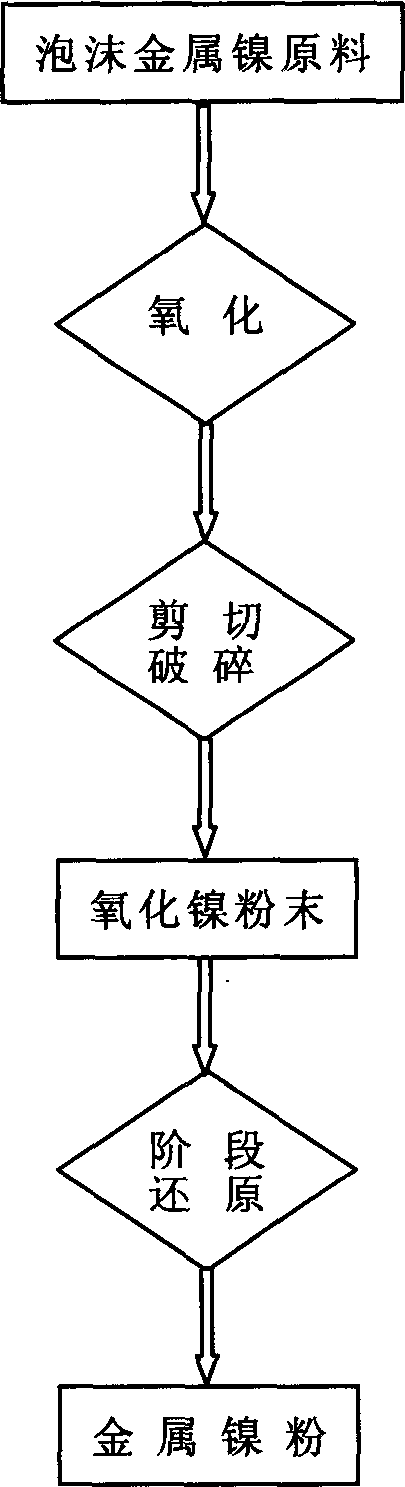

A high-performance nickel powder technology is applied in the field of low-cost and non-polluting refinement technology to prepare nickel powder. It can solve the problems of coarse powder particles, coarse particles, and difficulty in meeting market demand. It achieves fine particles, eliminates powder particle agglomeration, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

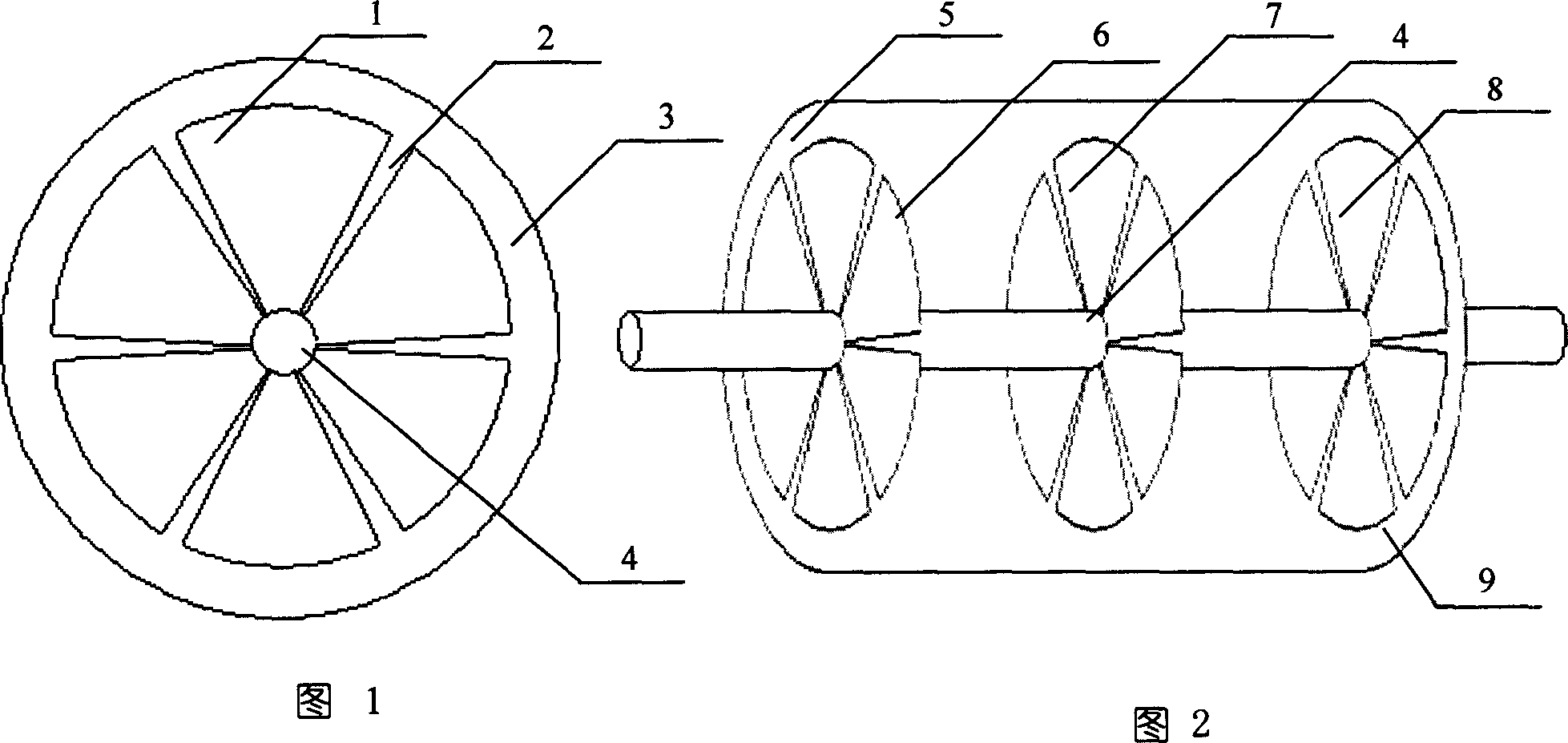

Embodiment 1

[0016] A dynamic rotary oxidation furnace is used to continuously oxidize the nickel foam raw material. The oxidation temperature is 860°C, the oxidation time is 15 minutes, and the rotation speed of the oxidation furnace is 25rpm. After the initial oxidation, the oxidation product is crushed by a multi-stage shear crusher, and the deformed martensitic strengthened steel Mn13 is used as the material for shearing and crushing blades in the shear crusher. The crushing time is 20 minutes, and the number of crushing stages is 2. Subsequently, the sheared and crushed product was subjected to secondary oxidation. The equipment used was a dynamic rotary oxidation furnace, the oxidation temperature was 860°C, the oxidation time was 10 minutes, and the rotation rate of the oxidation furnace was 35 rpm. The secondary oxidized nickel oxide powder is subjected to a three-stage reduction treatment using a horizontal continuous reduction furnace. The three-stage reduction temperatures are 4...

Embodiment 2

[0018] A dynamic rotary oxidation furnace is used to continuously oxidize the nickel foam raw material, the oxidation temperature is 900°C, the oxidation time is 20min, and the rotation speed of the oxidation furnace is 45rpm. After the initial oxidation, the oxidation product is crushed by a multi-stage shearing crusher, and the material used for the shearing and crushing blades in the shearing crusher is the deformed martensitic strengthened steel Mn13. The crushing time is 30 minutes, and the number of crushing stages is 3. Subsequently, the sheared and crushed product was subjected to secondary oxidation. The equipment used was a dynamic rotary oxidation furnace, the oxidation temperature was 870°C, the oxidation time was 15 minutes, and the rotation rate of the oxidation furnace was 55 rpm. The secondary oxidized nickel oxide powder is subjected to a three-stage reduction treatment using a horizontal continuous reduction furnace. The three-stage reduction temperatures are...

Embodiment 3

[0020] A dynamic rotary oxidation furnace is used to continuously oxidize the nickel foam raw material, the oxidation temperature is 950°C, the oxidation time is 30min, and the rotation speed of the oxidation furnace is 65rpm. After the initial oxidation, the oxidation product is crushed by a multi-stage shearing crusher, and the material used for the shearing and crushing blades in the shearing crusher is the deformed martensitic strengthened steel Mn13. The crushing time is 40min, and the crushing series is 4 grades. Subsequently, the sheared and crushed product was subjected to secondary oxidation. The equipment used was a dynamic rotary oxidation furnace, the oxidation temperature was 880°C, the oxidation time was 20 minutes, and the rotation rate of the oxidation furnace was 70 rpm. The secondary oxidized nickel oxide powder is subjected to a three-stage reduction treatment using a horizontal continuous reduction furnace. The three-stage reduction temperatures are 480°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com