Carboxylate polymer dispersant with deforming function

A technology of dispersant and carboxylate, which is applied in the field of deep processing of petroleum downstream products, can solve the problems of toxicity of quaternary ammonium salt, influence of application range, high reaction temperature, etc., to avoid uneven mixing, strong adaptability, and eliminate microporous structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

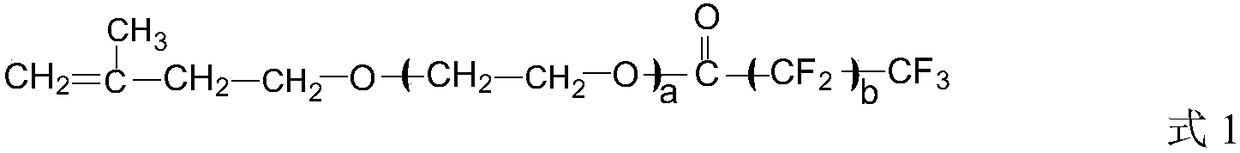

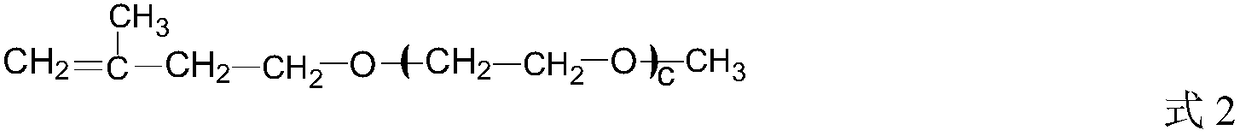

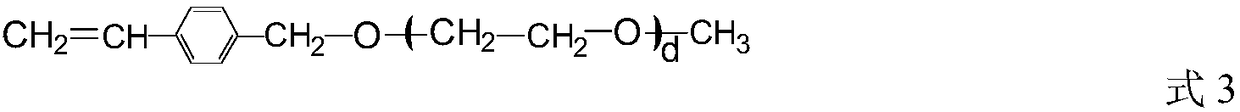

[0028] The molecular structural formulas of monomer A, isopentenyl unsaturated polyoxyethylene monomer B, and styrene-based polyoxyethylene monomer C with defoaming function are selected as follows:

[0029]

[0030]

[0031]

[0032] Among them, a=9, b=1, c=50, d=25.

[0033] The molar ratio of A:B:C:D reaction is: 1.0:2.5:1.0:16.0, wherein D is selected from acrylic acid. The polymerization preparation steps are as follows:

[0034] Put the isopentenyl polyoxyethylene macromonomer with a polyoxyethylene polymerization degree of 9 in a four-necked flask, select toluene as a solvent and hydroquinone as a polymerization inhibitor, heat the above mixture to 110°C, and add three Fluoroacetic acid, and after 10 minutes the catalyst p-toluenesulfonic acid was added. The reaction time was 8.0 hours. During the reaction, the esterification reaction water in the water separator was removed from the reaction system, and the reaction was terminated when the water yield was 10...

Embodiment 2

[0037] The molecular structural formulas of monomer A, isopentenyl unsaturated polyoxyethylene monomer B, and styrene-based polyoxyethylene monomer C with defoaming function are selected as follows:

[0038]

[0039]

[0040]

[0041] Among them, a=29, b=6, c=110, d=17.

[0042] The molar ratio of A:B:C:D reaction is: 1.0:5.0:0.7:35.0, wherein D selects itaconic acid. The polymerization preparation steps are as follows:

[0043] Put the isopentenyl polyoxyethylene macromonomer with a polyoxyethylene polymerization degree of 29 in a four-necked flask, select toluene as the solvent and hydroquinone as the polymerization inhibitor, heat the above mixture to 110°C, and add fluorine Caprylic acid, after 10 minutes, the catalyst concentrated sulfuric acid was added. The reaction time was 7.0 hours. During the reaction, the esterification reaction water in the water separator was removed from the reaction system, and the reaction was terminated when the water yield was 105% ...

Embodiment 3

[0046] The molecular structural formulas of monomer A, isopentenyl unsaturated polyoxyethylene monomer B, and styrene-based polyoxyethylene monomer C with defoaming function are selected as follows:

[0047]

[0048]

[0049]

[0050] Among them, a=60, b=5, c=9, d=6.

[0051] The molar ratio of A:B:C:D reaction is: 1.0:0.3:1.0:3.0, wherein D selects maleic anhydride. The polymerization preparation steps are as follows:

[0052] Put the isopentenyl polyoxyethylene macromonomer with a polyoxyethylene polymerization degree of 60 in a four-necked flask, select toluene as a solvent and hydroquinone as a polymerization inhibitor, heat the above mixture to 110°C, and add all Fluorohexanoic acid, after 10 minutes, the catalyst concentrated sulfuric acid was added. The reaction time was 9.0 hours. During the reaction, the effluent of the esterification reaction in the water separator was removed from the reaction system, and the reaction was terminated when the water yield w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com