Sintered NdFeB powder orienting method

A technology of NdFeB and powder, which is applied in the field of orientation of sintered NdFeB powder, which can solve problems such as uneven density of blanks, reduction of magnetic properties consistency of sintered NdFeB blanks, unequal arrangement position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

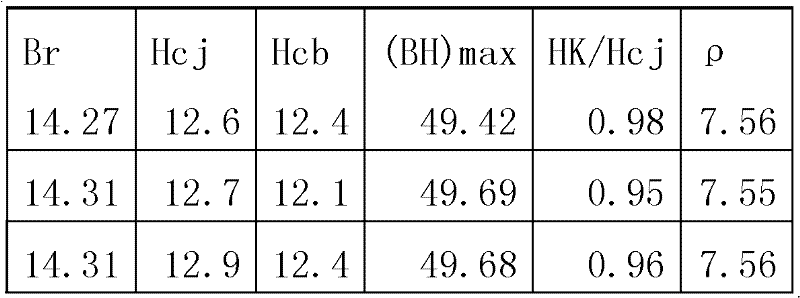

Examples

Embodiment Construction

[0012] A method for the orientation of sintered NdFeB powder includes the following steps:

[0013] a. Put the neodymium iron boron blank powder into the mold cavity;

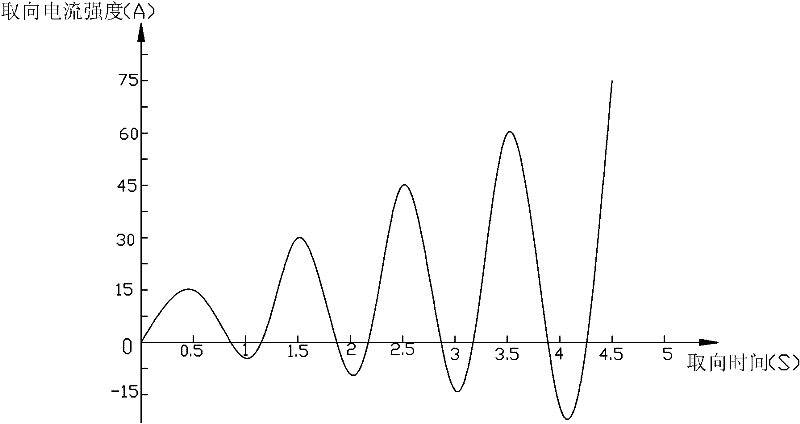

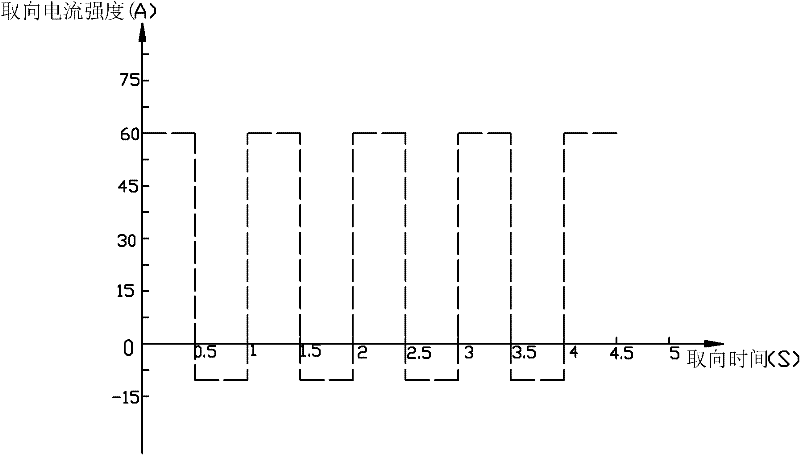

[0014] b. The poles on both sides of the press are fed with vibration or alternating current to form a vibrating magnetic field;

[0015] c. Mold pressing;

[0016] d. After the pressing is completed, apply a small reverse current to the poles on both sides to demagnetize and obtain the blank.

[0017] The poles on both sides of the press pass current in the same direction with the interval increased to the saturation magnetic field strength or add positive and reverse currents to form a vibrating magnetic field. The neodymium iron boron powder produces jitter in the mold cavity, which greatly eliminates the neodymium iron boron The agglomeration of powder increases the degree of orientation, and the consistency of the magnetic properties of each part of the blank is better. During the shaking process, the powder is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com