Technology for preparing nanometer rare-earth oxide

A nano-rare earth and oxide technology, applied in the direction of rare earth metal compounds, chemical instruments and methods, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of high equipment requirements, uneven particles, uneven particle size, etc. Achieve the effect of eliminating agglomeration, small and uniform particles, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

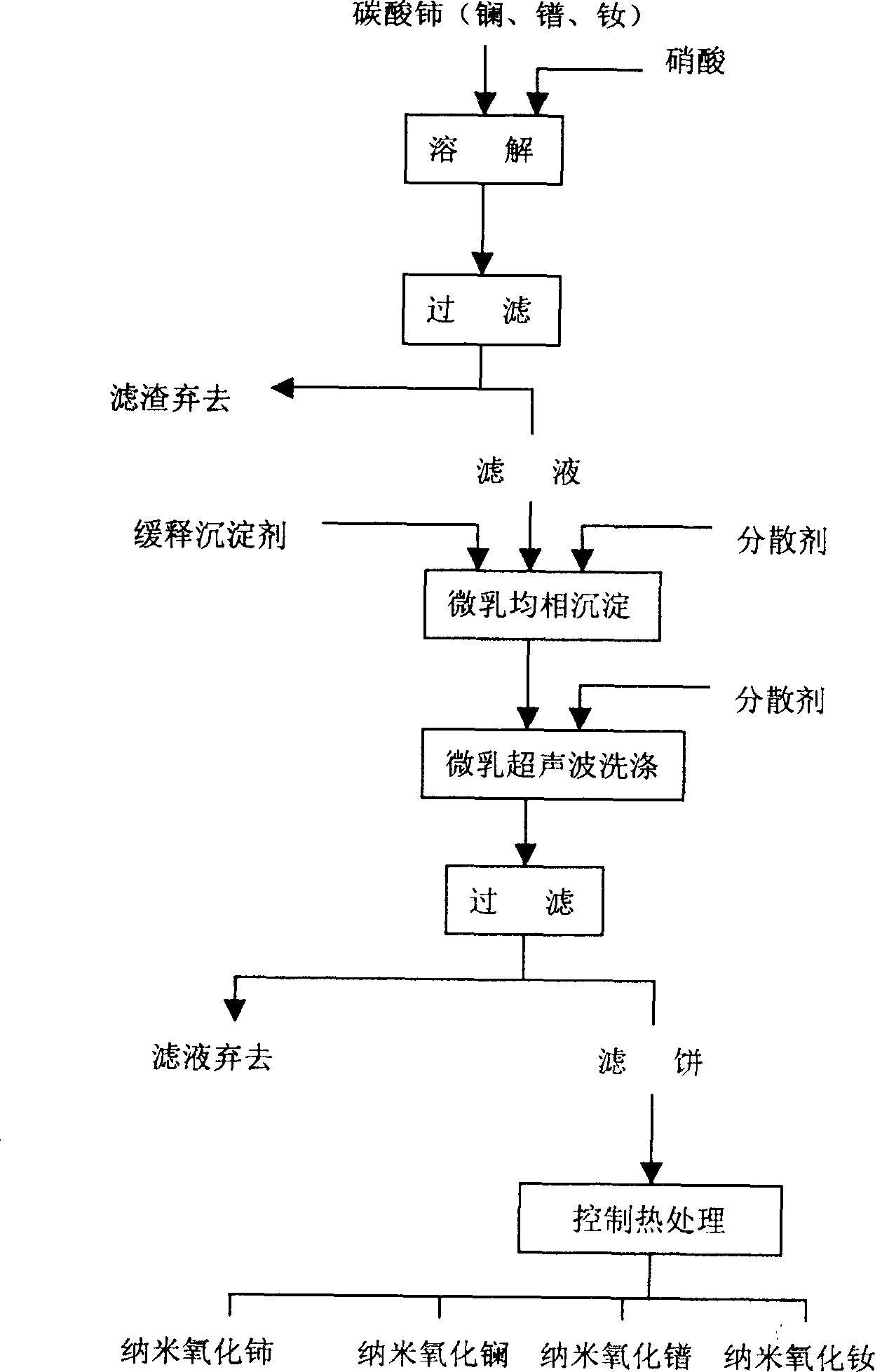

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: get 44 grams of cerium carbonate (CeO 2 45%), dissolved with 1:1 nitric acid, adjusted to PH 4, filtered, added 330 grams of urea to the solution, diluted to 1 liter with deionized water, added 5% (V / V) n-amyl alcohol, mixed, adjusted To pH 7, keep at 82±2°C for 2 hours, settle for 4 hours, take out the supernatant, add 1% (V / V) n-amyl alcohol to the precipitate, connect an ultrasonic generator, and wash at a temperature of 50±5°C. Time is 2 hours, filter, the filter cake is dried at 80°C for 2 hours, and then calcined at 500°C for 2 hours to obtain nano-cerium oxide with a central particle size of D 50 30nm..

Embodiment 2

[0011] Embodiment 2: get 88 grams of cerium carbonate (CeO 2 45%), dissolved with 1:1 nitric acid, adjusted to PH 4, filtered, added 660 grams of urea in the solution, diluted to 2 liters with deionized water, added 10% (V / V) n-amyl alcohol, mixed, adjusted to PH 7, keep at 85±2°C for 1.5 hours, settle for 4 hours, take out the supernatant, add 2% (V / V) n-amyl alcohol to the precipitate, connect the ultrasonic generator, wash, the temperature is 40±5°C, time Filter for 1 hour, dry the filter cake at 80°C for 2 hours, and then calcinate at 500°C for 2 hours to obtain nano-cerium oxide with a central particle size of D 50 29nm..

Embodiment 3

[0012] Embodiment 3: get 44 grams of lanthanum carbonate (La 2 o 3 43%), dissolved with 1:1 nitric acid, adjusted to PH 4, filtered, added 330 grams of urea to the solution, diluted to 1 liter with deionized water, added 5% (V / V) n-amyl alcohol, mixed, adjusted To pH 7, keep at 82±2°C for 2 hours, settle for 4 hours, take out the supernatant, add 1% (V / V) n-amyl alcohol to the precipitate, connect an ultrasonic generator, and wash at a temperature of 50±5°C. After 2 hours, filter, and dry the filter cake at 80°C for 2 hours, then calcinate at 500°C for 2 hours to obtain nano-lanthanum oxide with a central particle size of D 50 28nm..

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com