Cellulose triacetate film

A technology of cellulose triacetate and ester film, which is applied to other household appliances, coatings, flat products, etc., and can solve the problems of high crystal points of triacetate cellulose film, long grinding time of matting agent, and shortened service life of filter elements, etc. problems, to achieve the effect of reducing the ills of the crystal point, reducing the stirring frequency and prolonging the life of the filter element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation of cellulose triacetate cotton glue solution mainly includes three processes of cotton glue solution preparation, cotton glue solution filtration and constant temperature static defoaming.

[0034] (1) Cotton Glue Preparation

[0035] First, add the mixed solvent and additives to the reaction kettle, turn on the stirring device of the reaction kettle and the temperature control device of the jacket water, effectively control the speed range, and mix evenly. Secondly, mix the cellulose triacetate and the broken film according to the formula ratio and add them to the reaction kettle containing the mixed solvent and additives; adjust the stirring speed, jacket water temperature and other dissolution process parameters to dissolve the cellulose triacetate , the dissolution time was 6h, and a uniform and transparent cellulose triacetate cotton glue solution was prepared.

[0036] (2) Filtration of cotton glue solution

[0037] Cotton glue liquid is usually ...

Embodiment 1

[0048]

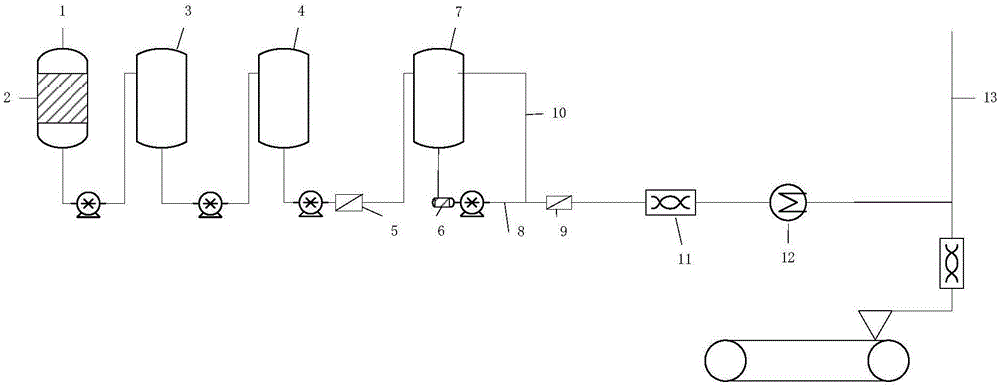

[0049] Take 10Kg of cellulose triacetate, 5Kg of cosolvent, and 0.5Kg of plasticizer, add them into 50Kg of mixed solvent and fully dissolve them to prepare a cotton glue solution for future use. Add 1.5Kg of matting agent into the dispersion tank containing dilute cotton gum 1, and use ultrasonic device 2 and mechanical agitation to disperse and process for 30 minutes to obtain a dispersion. Wherein, frequency of ultrasonic device 2: 40KHz, frequency of mechanical stirring: 35Hz. Put the dispersion liquid into the ball mill 3 for grinding treatment, the time is 100 min, the particle content of <10 μm: 99.8%, to obtain the grinding liquid. After being ultrasonicated by the pipeline of the second ultrasonic device 6, part of the grinding liquid returns to the storage tank 7 through the return pipeline 10 at a certain flow rate, and part of it enters the filter 9 through the ultrasonic pipeline 8 to be filtered. The frequency of the second ultrasonic device 6 is 10K...

Embodiment 2

[0051] The difference from Example 1 is that the dispersing time of the matting agent dispersion liquid is 25min, the frequency of the ultrasonic device 2 is 50KHz, and the mechanical stirring frequency is 20Hz. The processing time of the grinding liquid is 110 minutes, the particle content of <10 μm: 99.9%, the frequency of the second ultrasonic device 6: 20KHz, the flow rate of the ultrasonic pipeline 8: 15L / h, and the flow rate of the return pipeline 10: 10L / h. Put it in the storage room after being rolled into a shaft, and moisture absorption will appear after 17 days. The test data of the above-mentioned thin film products are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com