Method for improving dispersibility of organic soil

A dispersive and organic soil technology, applied in the field of organic soil applications, can solve the problems of poor stability and poor dispersion performance of colloidal dispersion systems, and achieve the effects of wide application, improved dispersion and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, the organic soil dispersion system is first prepared, and an appropriate amount of oil-soluble nonionic surfactant is added to the organic soil dispersion system, and the dispersibility is obtained through appropriate shearing (weak shearing is used in the stirring methods in the examples). Better and more stable organic soil dispersion system, the specific process is as follows:

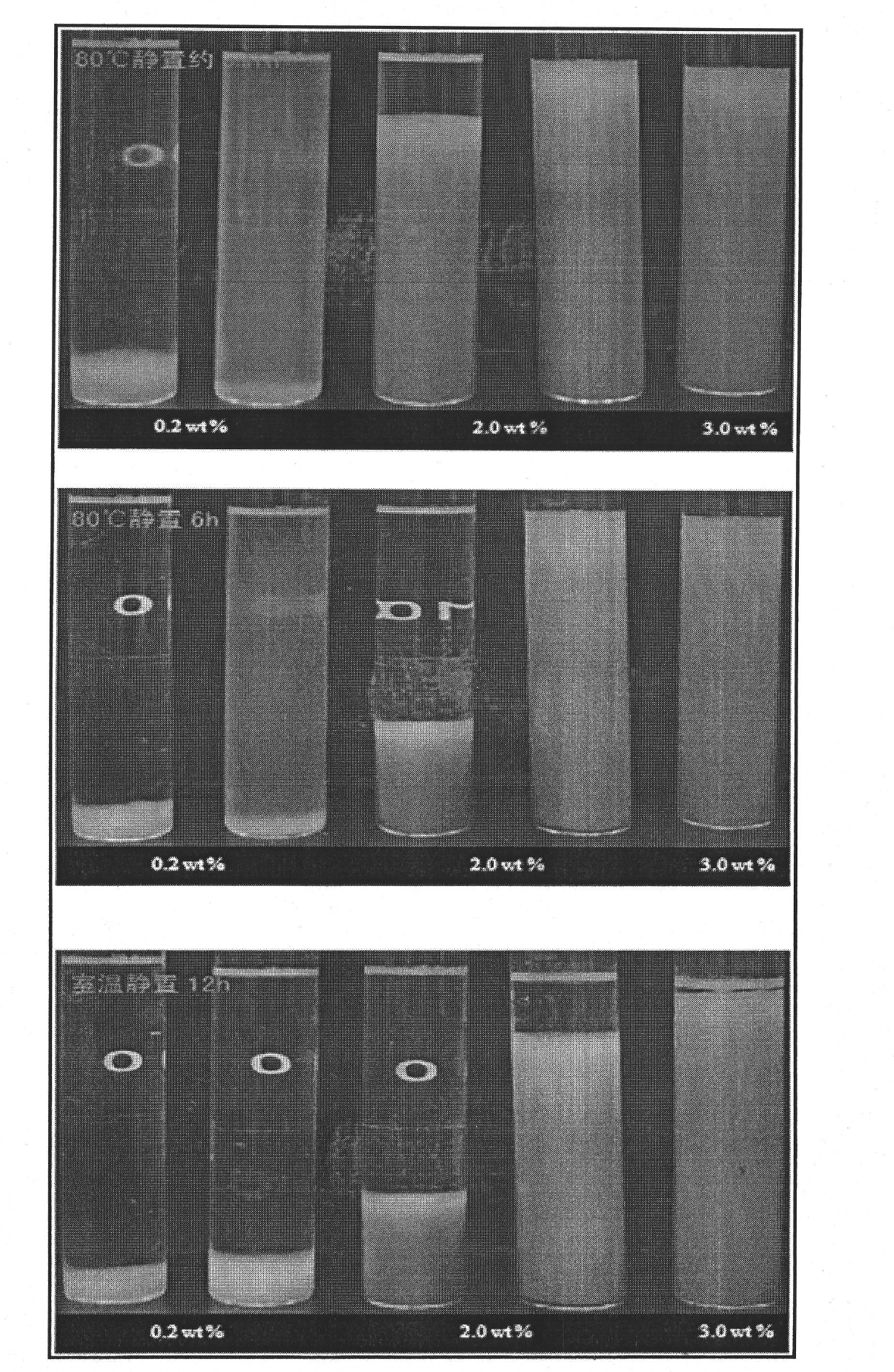

[0020] Disperse 0.3g of organic soil in a corresponding amount of gas-oil, and then add 0.09g of Span-80 (S80, accounting for 30% of the mass of organic soil) to the dispersion system to prepare organic soil with a mass fraction of organic soil of 2%. Earth gas oil dispersion system (2.0wt%), the mixture (total weight 15g) was electromagnetically stirred at room temperature at a speed of 300 revolutions per minute for 12 hours, then transferred to a 25ml colorimetric tube, left to stand, and the ratio was recorded for 90 minutes. The height of free oil precipitated from th...

Embodiment 2

[0026] The mass fraction of organic soil in embodiment 1 is changed from 2% to 5% (preparing organic soil mass fraction is 5% organic soil gas oil dispersion system), and Span-80 addition occupies 30% of organic soil quality by above Change to 10%, then electromagnetically stir at room temperature at a speed of 300 rpm for 30 minutes, while the rest of the conditions are the same, then transfer to a 25ml colorimetric tube, let it stand, and record for 90 minutes when free oil is precipitated from the upper part of the colorimetric tube height, and calculate the gelation rate of each system according to the method of Example 1, then the gelation rate comparison of the three organic soils without adding any additives and adding Span-80 is shown in the following table:

[0027] project

[0028] From the above data, it can be seen that under the conditions of small shearing force (small electromagnetic stirring force), short dispersion time, and a small amount of Span-80 ...

Embodiment 3

[0030] This example is an experiment on the colloidal stability of various organic soil dispersion systems.

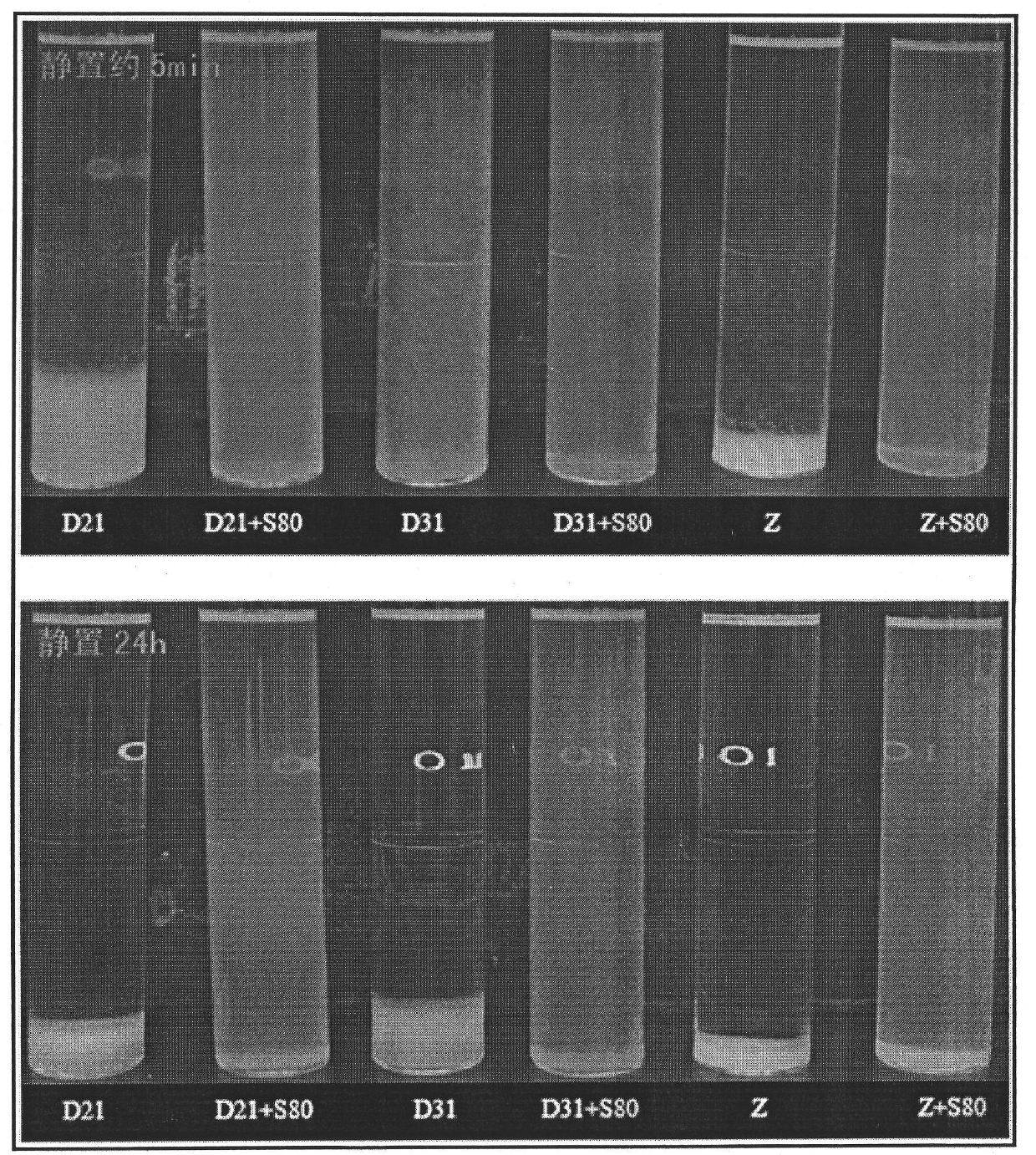

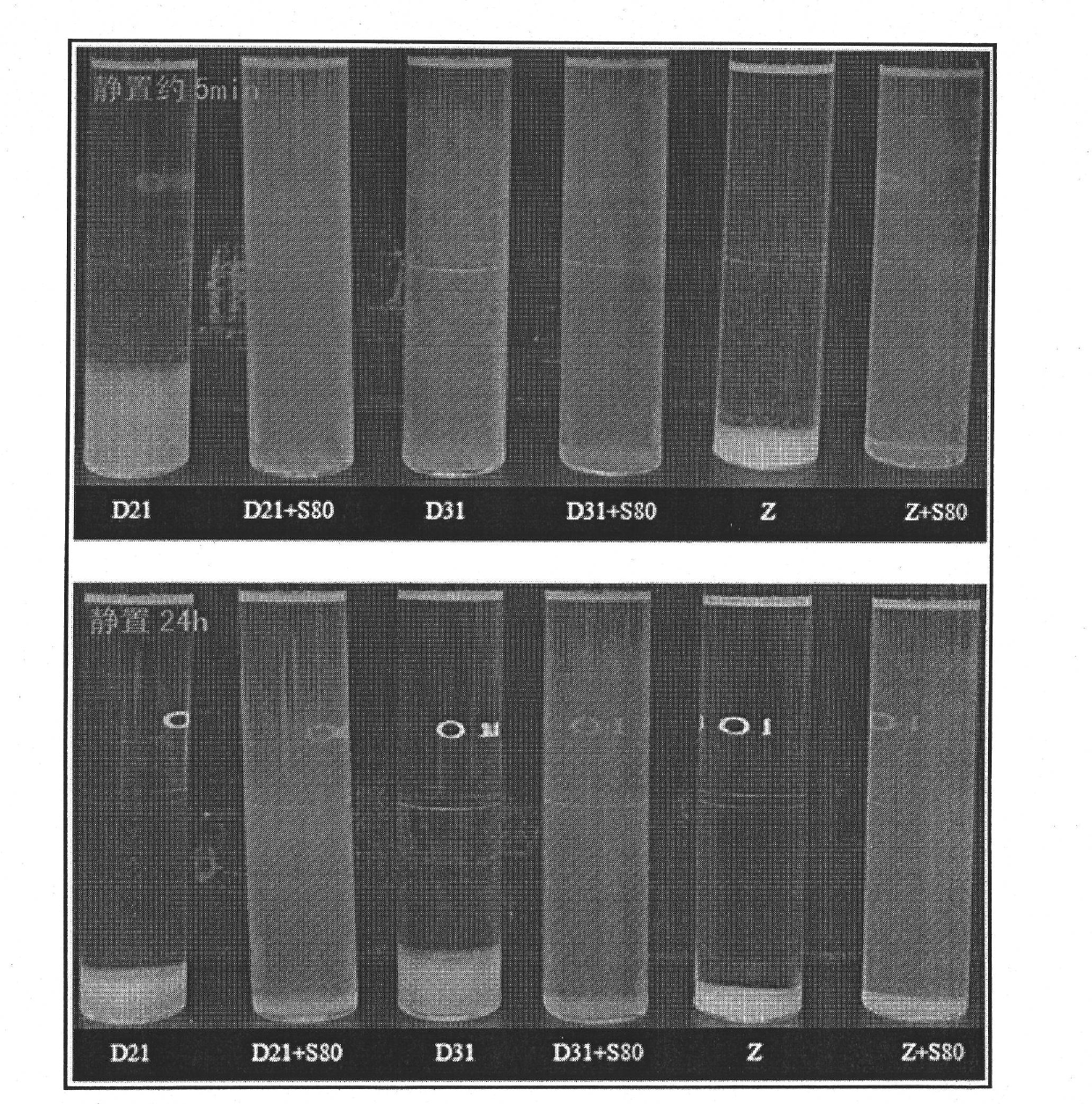

[0031] Disperse 0.03g organic soil in the corresponding amount of gas oil, add 0.06g Span-80 (200% of organic soil mass) to the dispersion system of the experimental group to form a mixture, while the control group does not add any additives to obtain the mass fraction It is a 0.2% organic soil gas oil dispersion system (0.2wt%), and then the mixture (total weight 15g) is placed on an electromagnetic stirrer, and is electromagnetically stirred at a speed of 300 revolutions per minute at room temperature for 12 hours, and then transferred to a 25ml colorimetric In the tube, stand still, take pictures after transferring and standing for 24 hours, the photos are as follows: figure 1 As shown, the upper part is the photo when the transfer is completed, and the lower part is the photo after standing for 24 hours. for figure 1 In the upper middle photo, the organic soil in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com