Method for improving comprehensive performance of carbon nanomaterial reinforced nickel-based superalloy

A technology of nickel-based superalloy and carbon nanomaterials, which is applied in the direction of nanotechnology, nanotechnology, metal material coating technology, etc., can solve the problems of poor mechanical properties and high-temperature oxidation resistance, reduced high-temperature oxidation resistance, and poor bonding of the substrate interface and other issues to achieve the effect of improving oxidation resistance, mechanical properties, and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

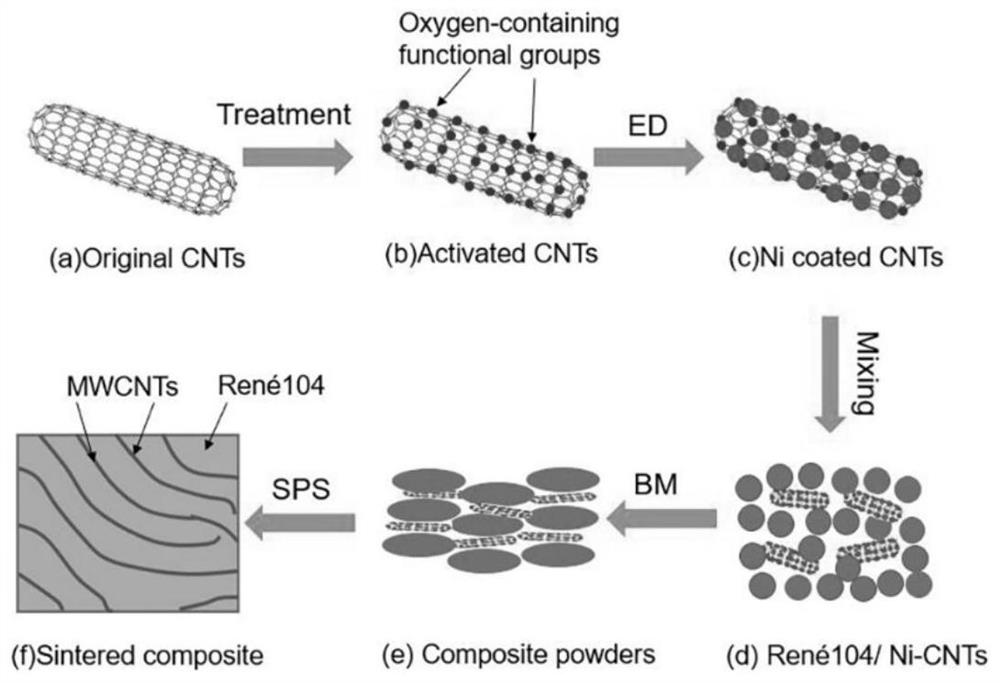

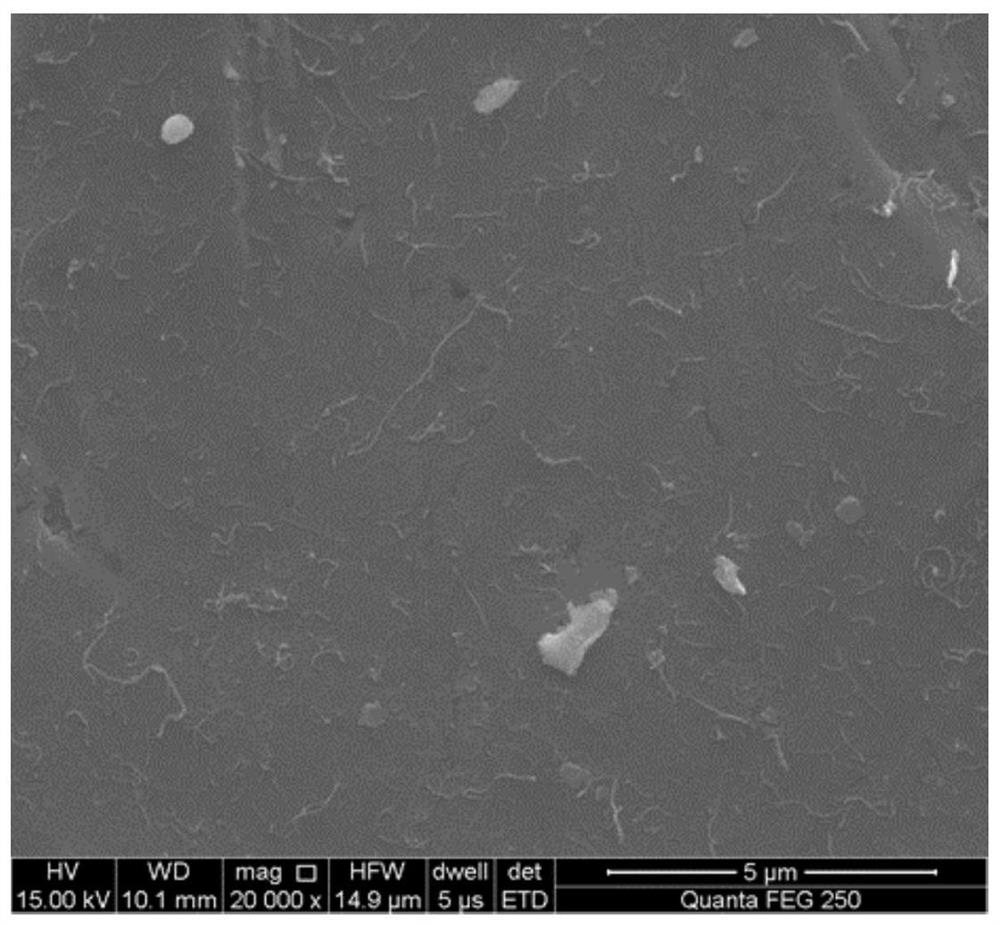

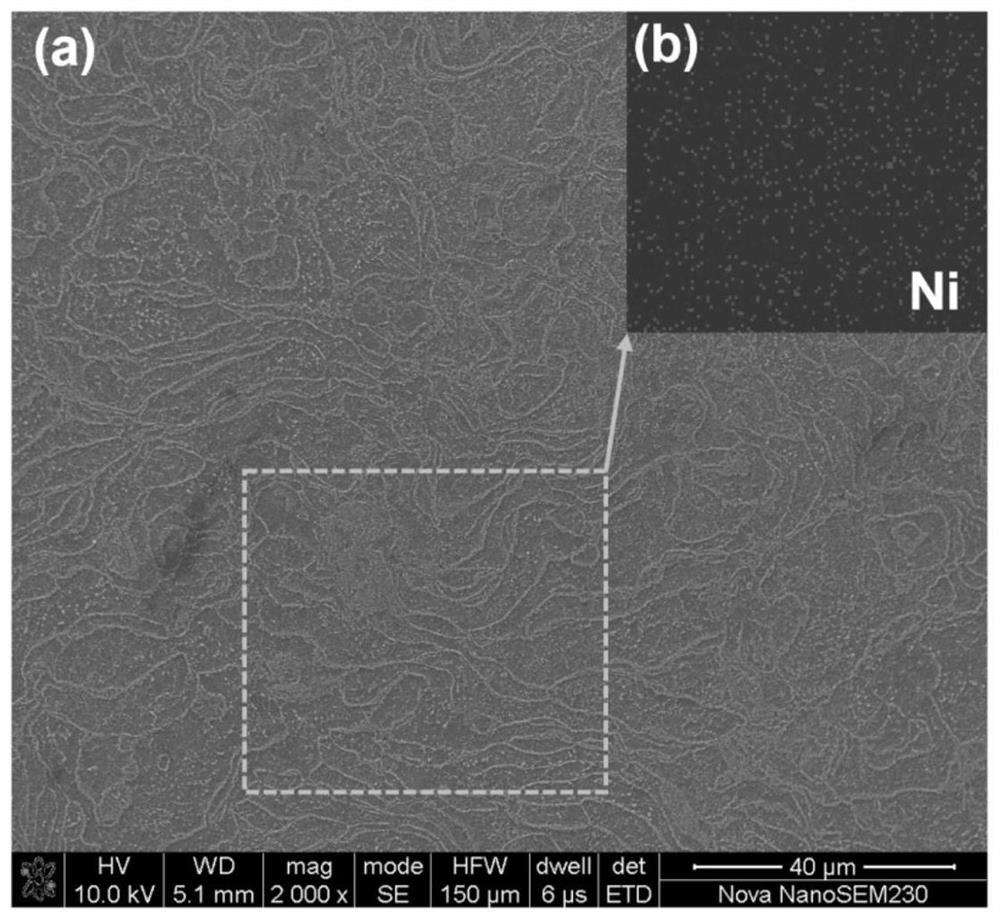

[0060] Schematic diagram of the formation of carbon nanotubes (CNTs) reinforced René 104 nickel-based superalloy composites. figure 1 shown. First, the original multi-walled carbon nanotubes were modified by electroless plating, and then formed by ball milling and SPS.

[0061] The specific steps of CNTs electroless nickel plating: the multi-walled carbon nanotubes are soaked in concentrated nitric acid for 24 hours, filtered and washed with deionized water until neutral. The purified multi-walled carbon nanotubes were magnetically stirred in an aqueous solution (0.1M tin chloride / 0.1M hydrochloric acid) at 30° C. for 35 minutes, and then ultrasonically oscillated for 10 minutes for sensitization. After washing with deionized water, the sensitized MWCNTs were immersed in an aqueous solution (0.0014 M PdCl and 0.25 M hydrochloric acid) and activated at 30 °C for 24 h. After washing, the activated multi-walled carbon nanotubes were placed in an electroless plating solution.

...

Embodiment 2

[0070] First, the original multi-walled carbon nanotubes were modified by electroless plating, and then 1.0wt.% Ni-CNTs and René104 powder were ball-milled together to prepare carbon nanotube-reinforced René104 composite samples by SLM.

[0071] The specific steps of CNTs electroless nickel plating: the multi-walled carbon nanotubes are soaked in concentrated nitric acid for 24 hours, filtered and washed with deionized water until neutral. The purified multi-walled carbon nanotubes were magnetically stirred in an aqueous solution (0.1M tin chloride / 0.1M hydrochloric acid) at 30° C. for 35 minutes, and then ultrasonically oscillated for 10 minutes for sensitization. After washing with deionized water, the sensitized MWCNTs were immersed in an aqueous solution (0.0014 M PdCl and 0.25 M hydrochloric acid) and activated at 30 °C for 24 h. After washing, the activated multi-walled carbon nanotubes were placed in an electroless plating solution.

[0072] Electroless plating was per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com