Hydrolysis hydrogen-production aluminum alloy and preparation method thereof

A technology for producing hydrogen and aluminum alloys by hydrolysis, which is applied in the field of metal materials, can solve the problems of low hydrogen production rate and hydrogen production rate of alloys, difficulty in meeting the requirements of hydrogen fuel cell vehicles, etc., and achieve reduced consumption, low cost and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a method for preparing an aluminum alloy for hydrogen production by hydrolysis, which uses components including the following mass contents as raw materials: 60-95wt% of Al, 0.5-10wt% of Ga, 0.5-10wt% of In, 0.5-10wt% of Sr, Bi 2 o 3 1~10wt%, SnCl 2 1 to 10 wt%, ball milling to obtain the hydrolyzed hydrogen-producing aluminum alloy.

[0019] In the present invention, the raw material includes Al with a mass content of 60-95 wt%, preferably 70-93 wt%, more preferably 85-90 wt%. In the present invention, the purity of the Al is preferably not lower than 99%. In the present invention, the Al is preferably Al powder; the size of the Al powder is preferably 100-200 mesh, more preferably 140-160 mesh. In the present invention, the activated Al reacts with water to generate hydrogen.

[0020] In the present invention, the raw material includes Ga with a mass content of 0.5-10 wt%, preferably 1-8 wt%, more preferably 1.5-5 wt%. In the present inv...

Embodiment 1

[0033] With 90wt% 100 mesh purity of 99% or more Al powder, 4.5wt% of 99.9% or more liquid Ga, 2.5wt% of 100 mesh purity of 99.9% or more In powder, 1wt% of 100 mesh purity is 99.99% or more of Sr powder, 0.5 wt% of Bi with a particle size of 200 mesh and a purity of 99.9% or more 2 o 3 and 1.5wt% of SnCl with a particle size of 50 mesh and a purity of 99% or more 2 As the raw material, the raw material and the grinding balls are placed in the ball milling tank and sealed in a glove box filled with argon gas. The ball-to-material ratio is 20:1. Ball milling in a ball mill at a speed of 500 r / min for 24 hours to obtain hydrolyzed hydrogen-producing aluminum alloy powder with a particle size of 200 μm.

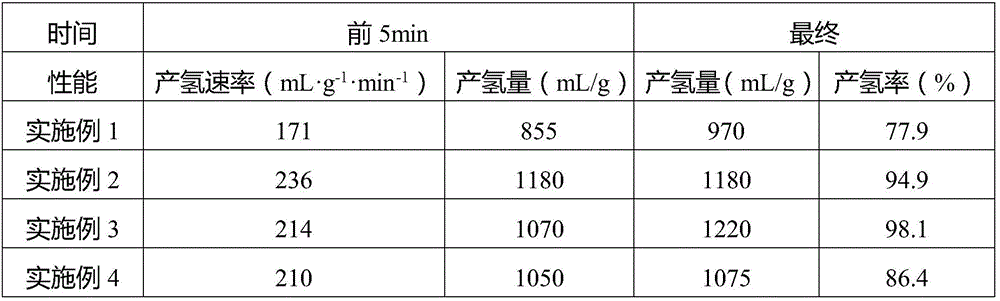

[0034] Mix the obtained aluminum alloy powder for hydrogen production by hydrolysis with water at 25°C for hydrolysis reaction, and test the hydrogen production performance by hydrolysis. The hydrolysis hydrogen production aluminum alloy powder reacts violently immediately af...

Embodiment 2

[0036] With 88.5wt% 150 mesh purity of 99% or more Al powder, 2.5wt% purity of 99.9% or more liquid Ga, 2wt% 150 mesh purity of 99.9% or more In powder, 1wt% 150 mesh purity of 99.99% or more of Sr powder, 1.5 wt% of Bi with a particle size of 300 mesh and a purity of 99.9% or more 2 o 3 and 4.5 wt% of SnCl with a particle size of 100 mesh and a purity of 99% or more 2 As the raw material, the raw material and the balls are placed in the ball mill pot and sealed in a glove box filled with argon gas. The ball-to-material ratio is 15:1. Ball milling in a ball mill at a speed of 400 r / min for 20 h to obtain hydrolyzed hydrogen-producing aluminum alloy powder with a particle size of 100 μm.

[0037] Mix the obtained aluminum alloy powder for hydrogen production by hydrolysis with water at 25°C for hydrolysis reaction, and test the hydrogen production performance by hydrolysis. The hydrolysis hydrogen production aluminum alloy powder reacts violently immediately after contacting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com