Nanometer hydroxyapatite dispersion body and preparation process thereof

A nano-hydroxyapatite and dispersion technology, applied in the field of nano-materials, can solve the problems of expensive surfactants, lower biological performance, and difficulty in complete removal, etc., achieve particle uniformity reduction, improve transparency, and save aging the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

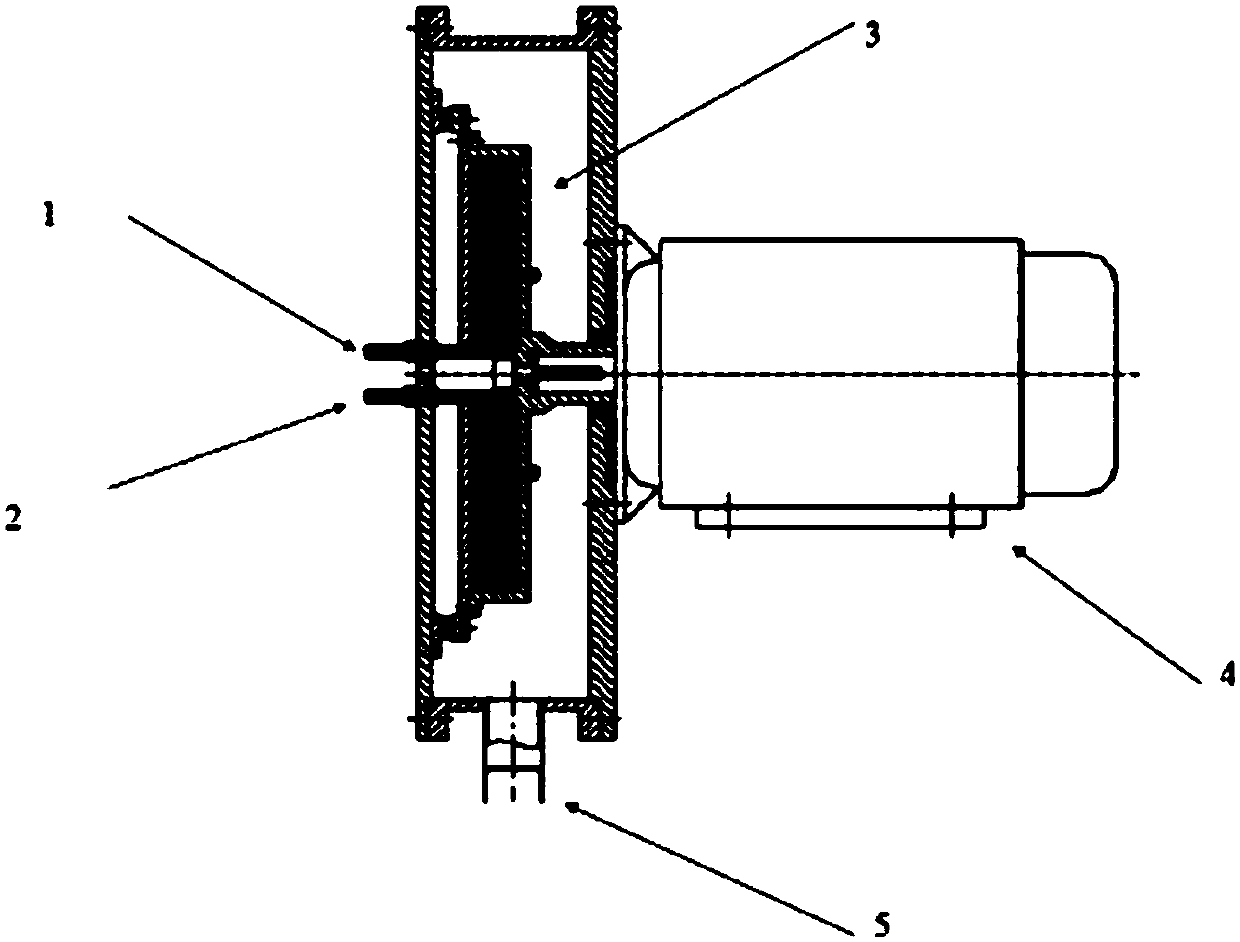

[0054] The high gravity rotary packed bed reactor used in the present invention is the prior art, and the schematic diagram of the high gravity rotary packed bed reactor is as follows figure 1 As shown, the meanings represented by the numbers in the figure are: 1-calcium salt solution inlet, 2-phosphate solution inlet, 3-filler, 4-motor, 5-suspension outlet.

[0055] A method for preparing a transparent nano-zirconia liquid phase dispersion by utilizing a high-gravity rotating packed bed reactor, comprising the following steps:

[0056] 1) Dissolve 4.72g of calcium nitrate tetrahydrate in 100ml of water to prepare an aqueous solution of calcium nitrate, add 1.176g of crystal form regulator sodium citrate, adjust the pH value to 11.5 with ammonia water, and use it as raw material A.

[0057] 2) Dissolve 1.584g of diammonium hydrogen phosphate in 60ml of water to prepare an aqueous solution of diammonium hydrogen phosphate, so that the ratio of calcium to phosphorus is 1.67, and...

Embodiment 2

[0067] 1) Dissolve 11.8g of calcium nitrate tetrahydrate in 100ml of water to prepare an aqueous solution of calcium chloride, add 3.0g of crystal form regulator sodium tripolyphosphate, adjust the pH value to 10.5 with ammonia water, and use it as raw material A.

[0068] 2) Dissolve 3.96 g of disodium hydrogen phosphate in 60 ml of water to prepare an aqueous solution of disodium hydrogen phosphate so that the ratio of calcium to phosphorus is 1.67, and add ammonia water to adjust the pH value to 10.5 as raw material B.

[0069] 3) Turn on the supergravity rotation device and adjust the rotation speed to 2000rpm;

[0070] 4) Turn on the peristaltic pump, control the flow rates to 1L / min and 0.6L / min respectively, and feed the two raw materials A and B into the high-gravity rotating bed using the peristaltic pump, and keep the calcium-phosphorus ratio at 1.67 at the two feeding rates. Control the temperature of the reaction system at 60° C. to carry out the reaction.

[0071...

Embodiment 3

[0076] 1) Dissolve 2.32g of calcium chloride tetrahydrate in 100ml of water to prepare an aqueous solution of calcium nitrate, add 0.5g of crystal form regulator water glass, and adjust the pH value to 10.5 with 1mol / L sodium hydroxide as raw material A.

[0077] 2) Dissolve 0.792 g of disodium hydrogen phosphate in 60 ml of water to prepare an aqueous solution of disodium hydrogen phosphate so that the ratio of calcium to phosphorus is 1.67. Add 1 mol / L sodium hydroxide to adjust the pH value to 10.5 as raw material B.

[0078] 3) Turn on the supergravity rotation device and adjust the rotation speed to 1500rpm;

[0079] 4) Turn on the peristaltic pump, control the flow rate to be 0.2L / min and 0.12L / min respectively, and feed the two raw materials A and B into the high-gravity rotating bed by using the peristaltic pump, and keep the calcium-phosphorus ratio at 1.67 at the two feeding rates. Control the temperature of the reaction system at 25° C. to carry out the reaction.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com