Ionic liquid grafted molecular sieve imidazole framework composite solid polymer electrolyte and preparation method thereof

A solid polymer, grafted molecule technology, applied in solid electrolytes, electrolytes, non-aqueous electrolytes, etc., can solve the problems of low ionic conductivity at room temperature, not meeting commercial requirements, etc., to improve ionic conductivity, improve mechanical properties, The effect of good electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

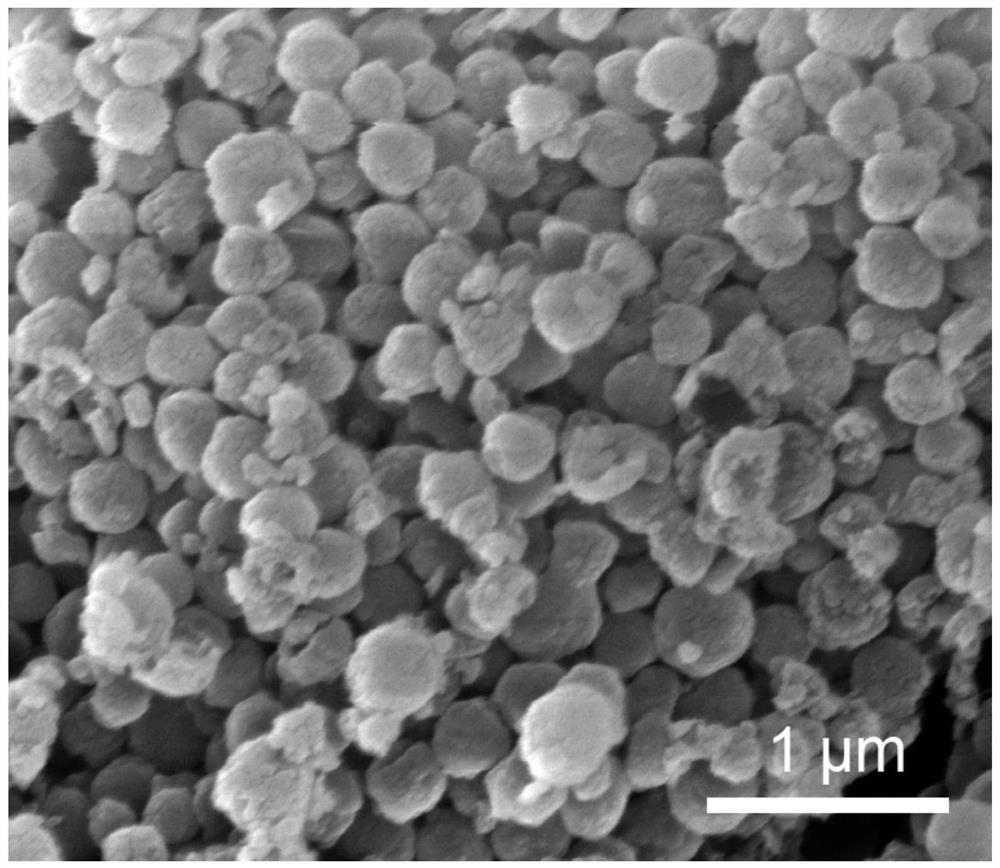

Image

Examples

preparation example Construction

[0038] A preparation method of ionic liquid grafted molecular sieve imidazole framework composite solid polymer electrolyte, comprising the following steps:

[0039] (1) Mix 3-chloropropyltrimethoxysilane and 1-methylimidazole, stir at 60-100°C for 48-96 hours, then add a certain amount of water, and stir evenly to obtain a solution of 0.05-0.5 g / mL; Dissolve a certain amount of lithium bistrifluoromethanesulfonylimide (LiTFSI) in water, stir well to obtain a solution of 0.05-0.5 g / mL; quickly mix the two solutions, stir for 6-18 hours, and extract the solution with dichloromethane After 3 to 5 times, the viscous liquid of siloxane-containing imidazolium quaternary ammonium salt ionic liquid (Si-IL) was obtained after rotary evaporation.

[0040] (2) Add 0.005g / mL ethylenediamine solution in methanol dropwise to the methanol dispersion of ZIF-90, stir evenly at 40-80°C for 12-36h, then centrifuge and wash with methanol three times; Vacuum drying at 40-80°C for 8-16 hours, gri...

Embodiment 1

[0050] The preparation method of imidazole quaternary ammonium salt grafted molecular sieve imidazole framework composite solid polymer electrolyte comprises the following steps:

[0051] (1) Take 2mL of 3-chloropropyltrimethoxysilane and 2mL of 1-methylimidazole and stir at 80°C for 72h, then add 10mL of water and stir evenly; dissolve 1g LiTFSI in water and stir evenly; mix the two The solution was quickly mixed and stirred for 12 h; the resulting solution was extracted 5 times with dichloromethane, and a viscous liquid of Si-IL was obtained after rotary evaporation.

[0052] (2) Add 50 μL of ethylenediamine into 10 mL of methanol and ultrasonically disperse evenly; add dropwise a solution containing 0.15 g of ZIF-90 dissolved in 30 mL of methanol, and stir at 60°C for 24 hours; centrifuge the product and wash it with methanol three times, Vacuum dried at 60°C for 12h and ground to obtain ZIF-90-NH 2 .

[0053] (3) Take 0.2g ZIF-90-NH 2 Add 30mL toluene and stir evenly; t...

Embodiment 2

[0058] The preparation method of imidazole quaternary ammonium salt grafted molecular sieve imidazole framework composite solid polymer electrolyte comprises the following steps:

[0059] (1) Take 2mL of 3-chloropropyltrimethoxysilane and 10mL of 1-methylimidazole and stir at 100°C for 48h, then add 10mL of water and stir evenly; dissolve 1g LiTFSI in water and stir evenly; mix the two The solution was quickly mixed and stirred for 12 h; the resulting solution was extracted 5 times with dichloromethane, and a viscous liquid of Si-IL was obtained after rotary evaporation.

[0060] (2) Take 50 μL of ethylenediamine and add it to 10 mL of methanol for ultrasonic dispersion; add dropwise a solution containing 0.15 g of ZIF-90 dissolved in 30 mL of methanol, and stir at 80°C for 24 hours; centrifuge the product and wash it with methanol three times, Vacuum dried at 80°C for 12h and ground to obtain ZIF-90-NH 2 .

[0061] (3) Take 0.2g from step (2) ZIF-90-NH 2 Add 30 mL of tolue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com