Efficient and refined medicinal material crushing machine

A refinement and pulverizer technology, applied in the field of high-efficiency and refined medicinal material pulverizers, can solve the problems of the deterioration of the quality of micro-pulverized products, the low pulverization efficiency of the pulverizer, and the low efficiency of material classification, so as to improve the pulverization effect, improve the quality, The effect of improving classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

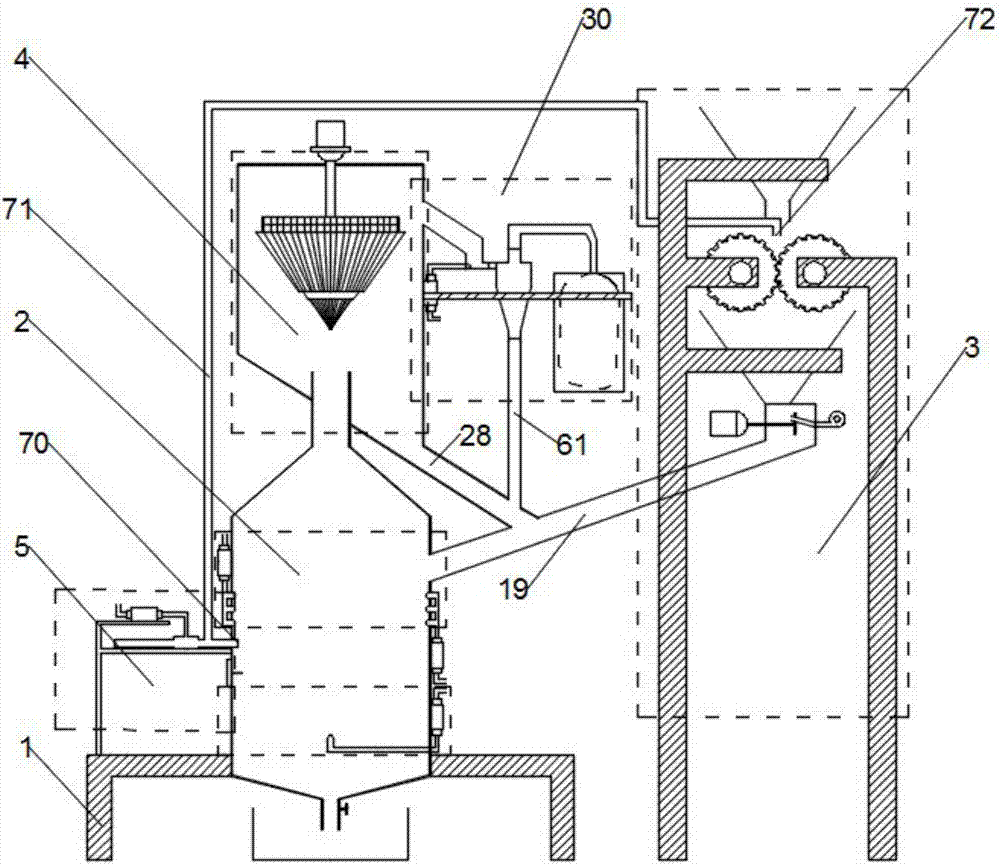

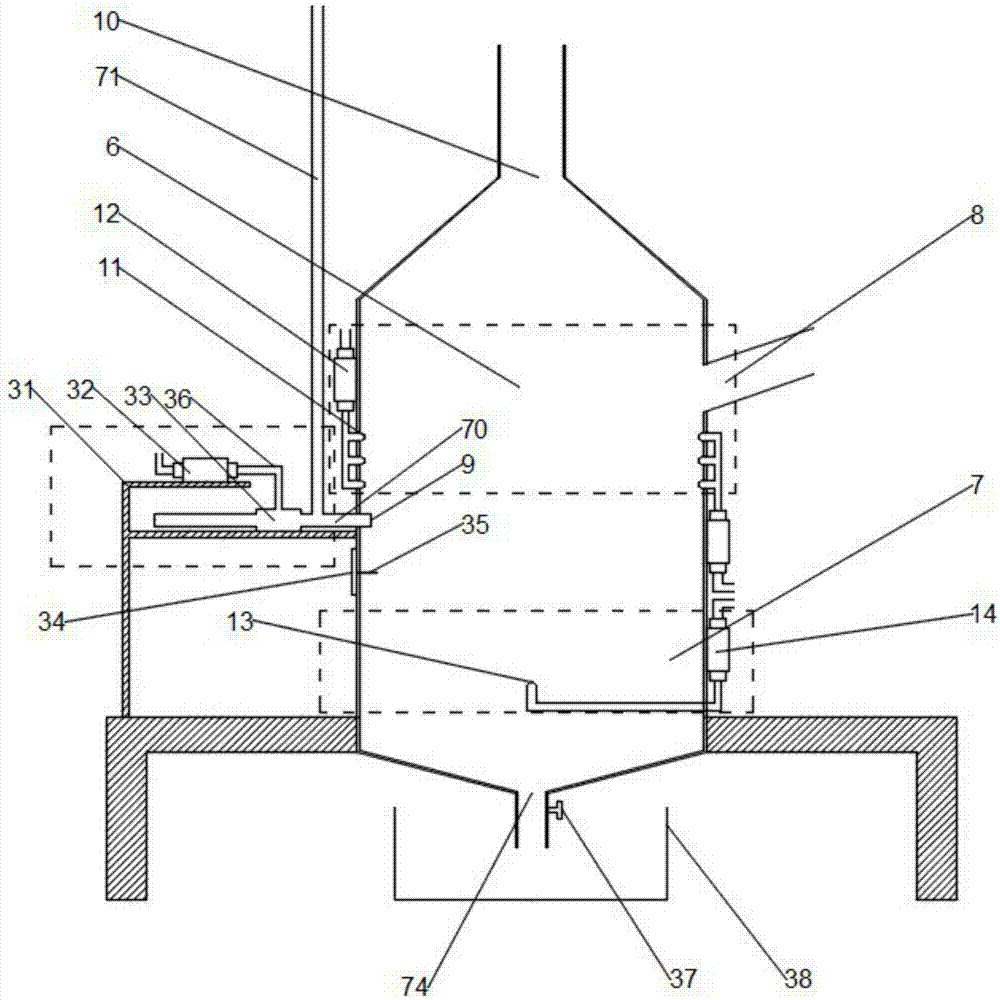

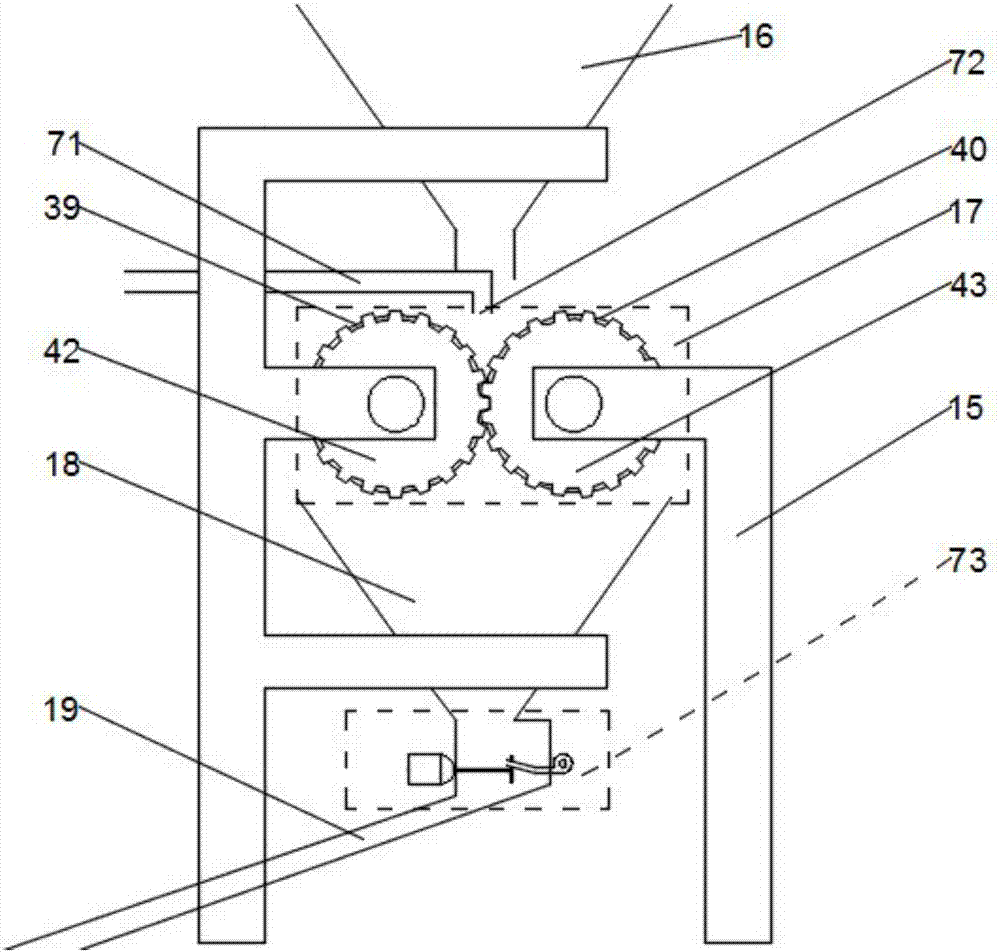

[0033] Such as Figure 1 to Figure 8 As shown, a high-efficiency and refined medicinal material pulverizer provided by the present invention includes a frame 1, a pulverization device 2 arranged on the frame 1, a feeding device 3 located on one side of the pulverization device 2, and a The classification device 4 and the cooling device 5 located on the other side of the crushing device 2.

[0034] Such as figure 1 with figure 2 As shown, the crushing device 2 includes a crushing chamber 6 arranged on the frame 1 and an air intake chamber 7 located below the crushing chamber 6. The crushing chamber 6 is a cylindrical structure with upper and lower openings. The crushing chamber 6 It is provided with a feed inlet 8, a cold air outlet 9, a discharge outlet 10 and a number of crushing nozzles 11. The crushing nozzles 11 are divided into two groups. The nozzle 11 is relatively arranged on the side wall of the crushing chamber 6, the feed inlet 8 and the cold air port 9 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com