Indigotin dyeing technique for warp yarn by using nano material and ultrasonic wave and device used therefor

A nano-material and ultrasonic technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of high dyeing cost, low dyeing rate, and long time consumption, and achieve the goal of increasing dyeing rate, reducing pollution, and eliminating agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

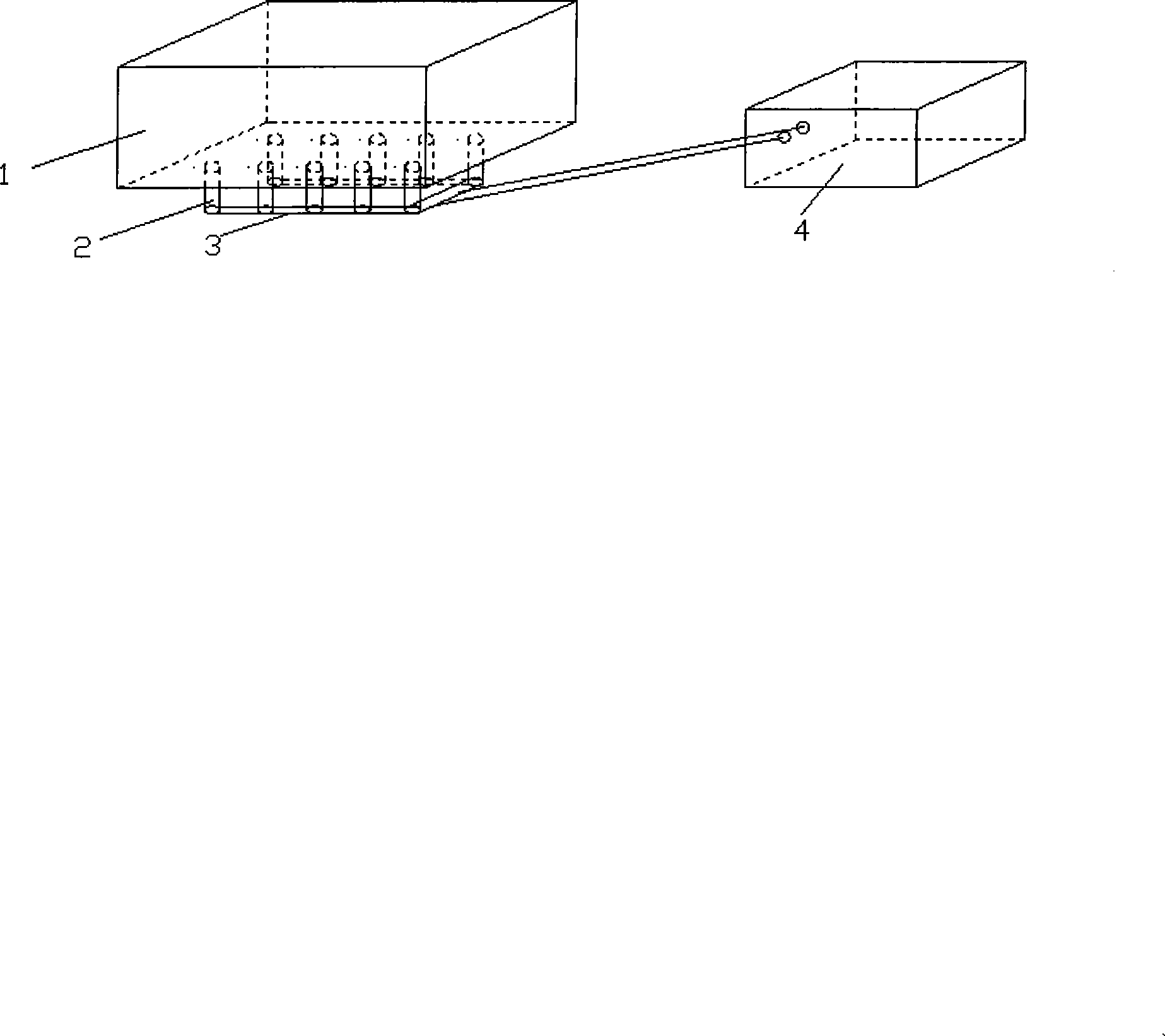

[0009] The device of the present invention has a stainless steel dye vat 1, 8-12 transducers 2 are arranged on the bottom surface in the stainless steel dye vat 1, all transducers 2 are connected in parallel by wires, and ultrasonic generator 4 is connected with the transducers 2 by wires 3.

[0010] Step 1: select the warp yarn with cotton content of 60%-70% and fineness of 80tex in the wetting solution with a temperature of 80°C, a concentration of caustic soda of 1.2g / L, and a concentration of penetrant of 1.8g / L Wetting treatment. Next, the wetted warp is washed in water at a temperature of 40°C to 45°C.

[0011] Step 2: first add 70% of its volume of water into the 1500L chemical tank, start the agitator, add caustic soda, penetrant, alcohol and indigo dye in turn, stir for 1 hour, wait for caustic soda, penetrant and indigo dye After fully melting, control the temperature to 40°C, then add sodium hydrosulfite while continuing to stir, and regularly heat to 50°C±1°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com