Double-fluid nozzle

A dual-fluid nozzle and main body technology, applied in the direction of liquid injection devices, injection devices, chemical instruments and methods, etc., can solve the problems of poor micronization performance and narrow use, and achieve the effect of promoting micronization and reducing liquid deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings, but the present invention is not limited to the illustrated embodiments, and various design changes can be made without departing from the gist of the present invention.

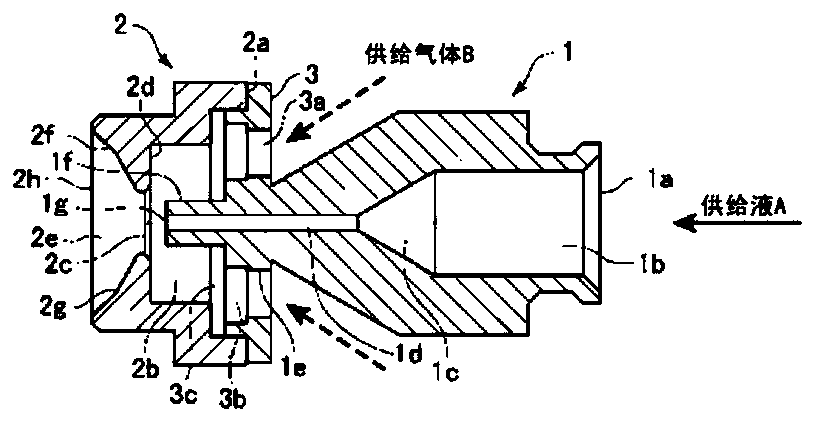

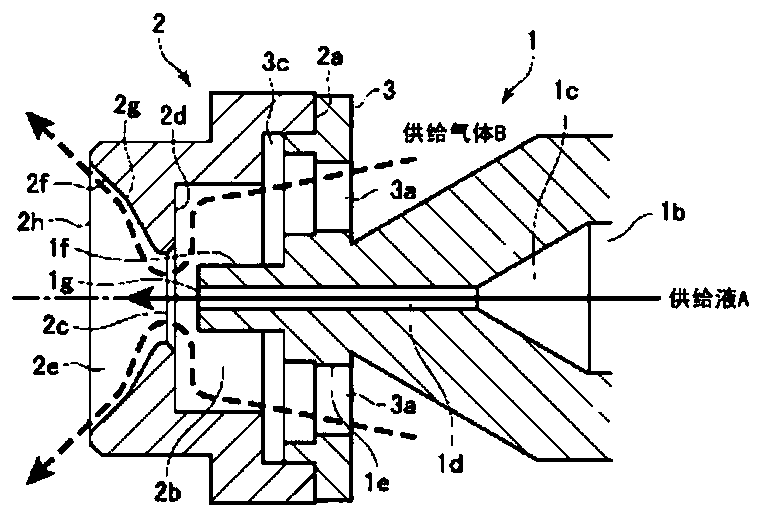

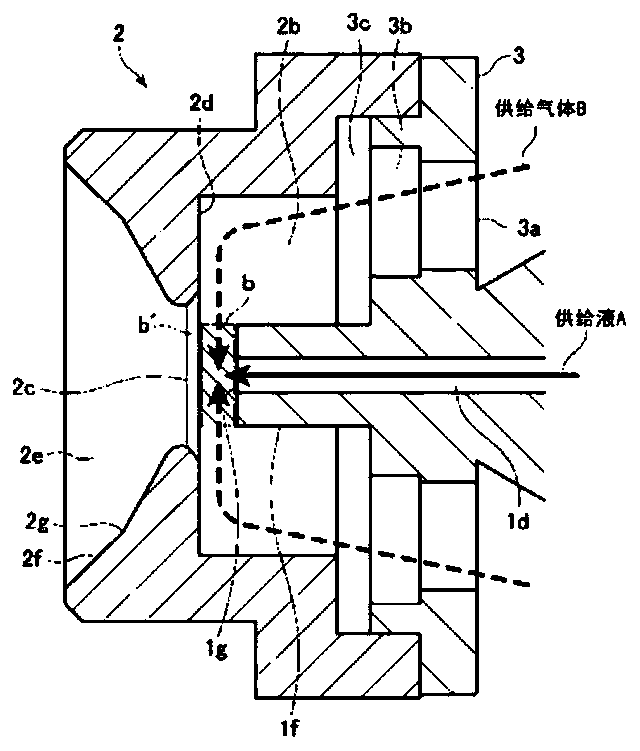

[0038] figure 1 An example of an internal mixing type two-fluid nozzle according to the present invention is shown. The two-fluid nozzle includes a liquid cap (Japanese: liquid cap) main body 1 and an air cap (Japanese: air cap) main body 2 provided on the downstream side tip of the liquid cap main body 1 .

[0039] The liquid cap main body 1 is hollow and opened on the right side in the figure, that is, the upstream side, and serves as a supply port 1a for supplying liquid A such as a mold release agent or an adhesive. Inside the liquid cap main body 1, a first fluid flow path 1b with a uniform inner diameter is formed linearly along the axial direction of the central portion, and a fluid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com