Novel waterborne zinc stearate emulsion, and preparation method thereof

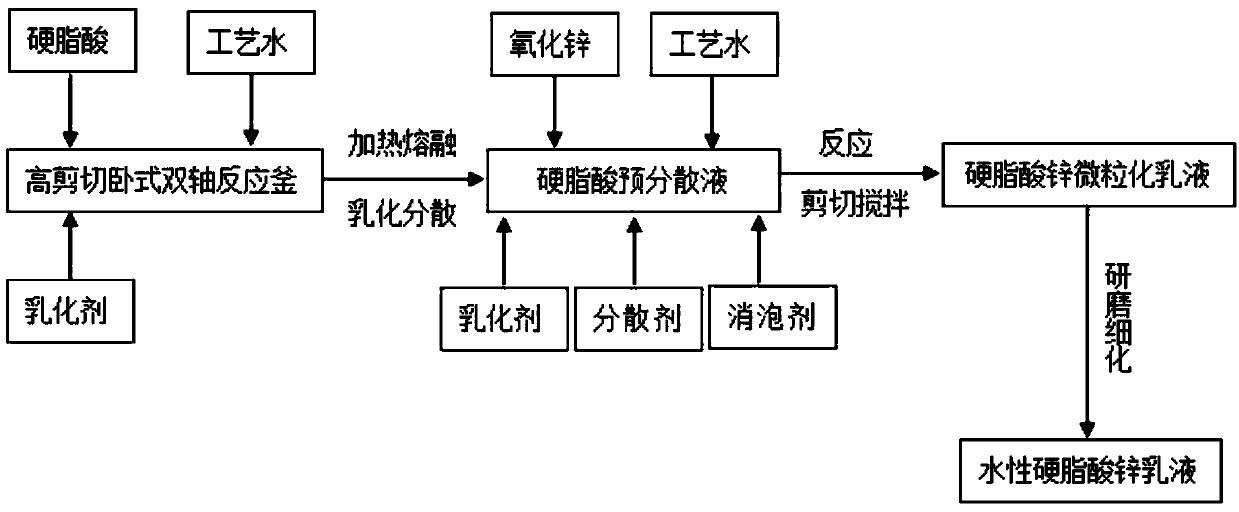

A technology of zinc stearate and stearic acid, which is applied in textiles and papermaking, fiber raw material processing, and paper forming additives addition, can solve the problems of high process cost, large product particle size, unfriendly environment, etc., and achieve increased The effect of contact area, no dust pollution, and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

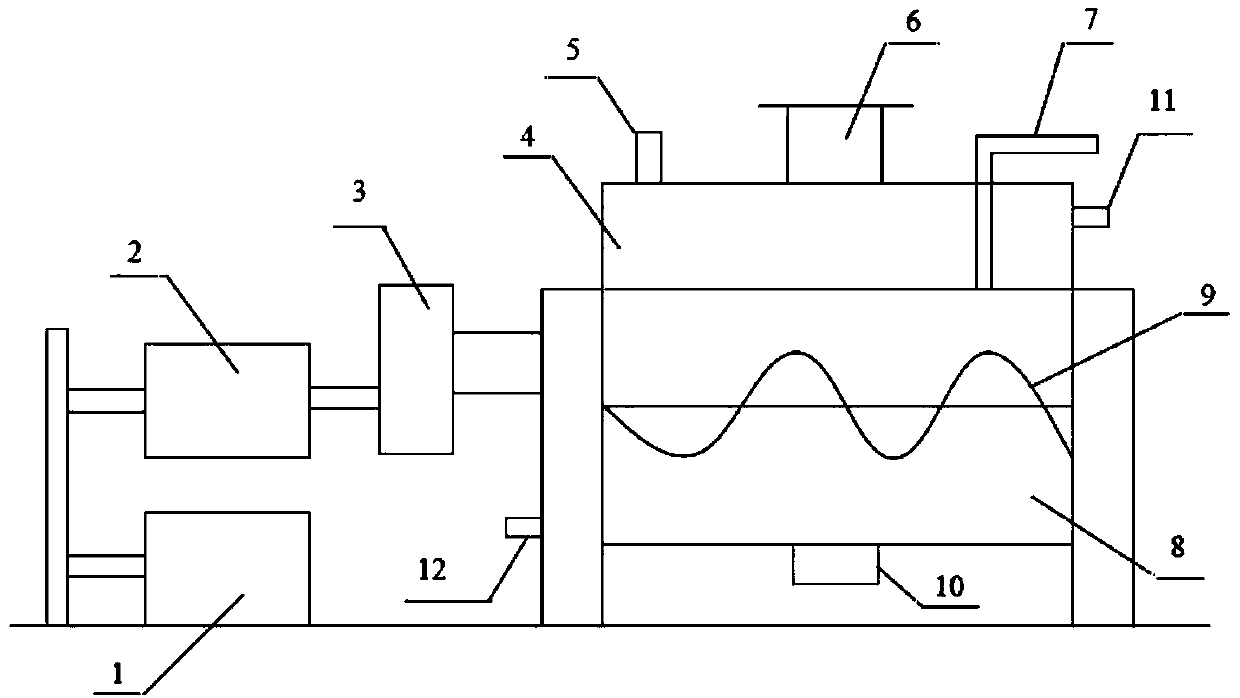

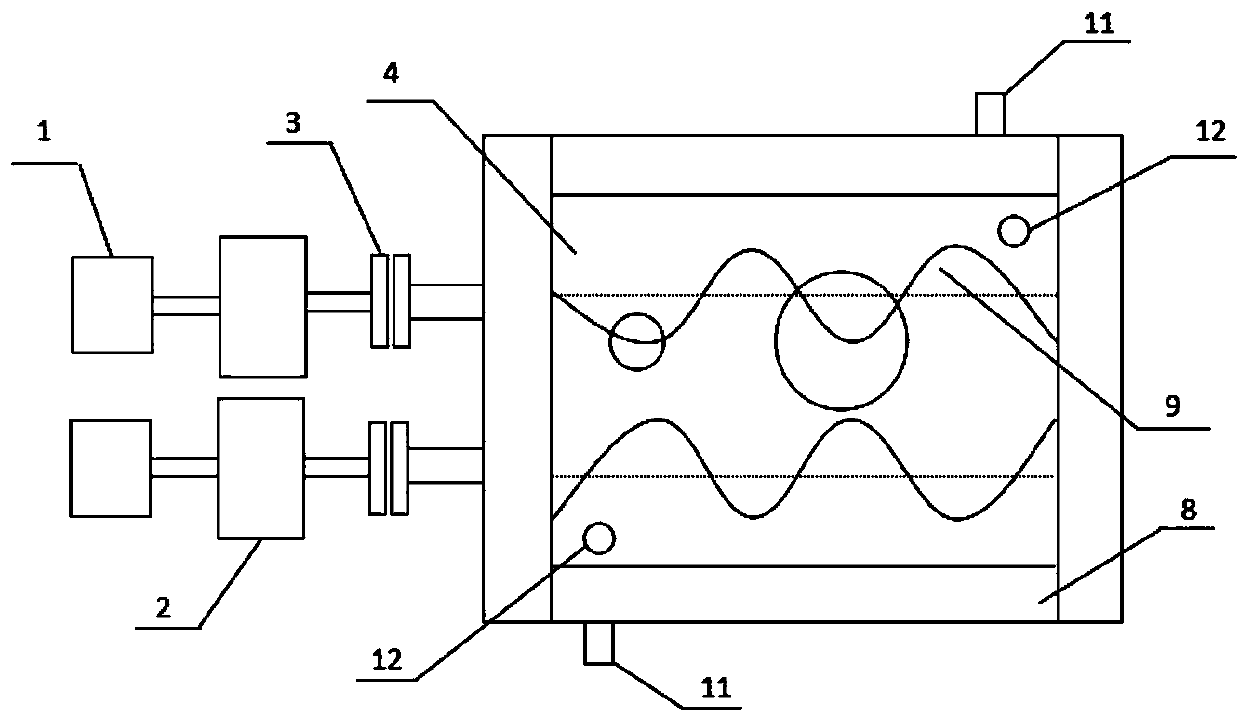

Method used

Image

Examples

Embodiment 1

[0039] Preparation of dispersion 1: Add 300kg of stearic acid, 450kg of deionized water, and 4kg of emulsifier hexadecyldimethylammonium bromide into a high-shear reaction kettle, stir and heat to 60°C for 10 minutes for pre-dispersion. Preparation of dispersion 2: Add 45.5 kg of zinc oxide, 250 kg of deionized water, 2 kg of emulsifier, and 5.2 kg of dispersant into a glass-lined reactor, and stir and mix to obtain a zinc oxide dispersion. Add the dispersion liquid 2 to the dispersion liquid 1, and fully react for 2 hours under high-shear stirring at a temperature of 60-80°C. Stop heating, quickly cool down to room temperature, add 5.5 kg of defoamer, and finally grind and refine for 2 hours to obtain the target product. The resulting product has a viscosity of 37.5mPa.S, a solid content of 32.3%, and an average particle size of 4.1μm. The product is uniform and stable without delamination. It can be used for metal cold extrusion, replacing the phosphating-saponification pro...

Embodiment 2

[0041] Preparation of dispersion 1: Add 350kg of stearic acid, 500kg of deionized water, and 8kg of emulsifier into a high-shear reaction kettle, stir and heat to 60°C for 10 minutes for pre-dispersion. Preparation of dispersion 2: Add 68 kg of zinc hydroxide, 100 kg of deionized water, 4 kg of emulsifier, and 5.5 kg of dispersant into a glass-lined reactor, and stir and mix to obtain a zinc hydroxide dispersion. Add the dispersion liquid 2 to the dispersion liquid 1, and fully react for 2 hours under high-shear stirring at a temperature of 60-80°C. Stop heating, quickly cool down to room temperature, add 5.5 kg of defoamer, and finally grind and refine for 3 hours to obtain the target product. The resulting product has a viscosity of 52.4mPa.S, a solid content of 37.8%, and an average particle size of 3.5μm. The product is uniform and stable without delamination. It can be used for thermal paper and special paper surface coating to improve printability and reduce the frictio...

Embodiment 3

[0043] Preparation of dispersion 1: Add 380kg of stearic acid, 500kg of deionized water, and 12kg of emulsifier into a high-shear reaction kettle, stir and heat to 60°C for 10 minutes for pre-dispersion. Preparation of dispersion 2: Add 82kg of zinc carbonate, 100kg of deionized water, 6kg of emulsifier, and 6.5kg of dispersant into a glass-lined reactor, and stir and mix to obtain a zinc carbonate dispersion. Add dispersion liquid 2 to dispersion liquid 1, stir under high shear at a temperature of 60-80° C., and fully react for 2 hours. Stop heating, quickly cool down to room temperature, add 6.0 kg of defoamer, and finally grind and refine for 3 hours to obtain the target product. The resulting product has a viscosity of 72mPa.S, a solid content of 40.5%, and an average particle size of 1.5μm. The product is uniform and stable without delamination. It can be used in water-based coatings to improve the hydrophobicity of coatings and the feel of coating films.

[0044] The h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com