Fuel Injection Valve

A fuel injection valve and fuel injection technology, applied in fuel injection devices, charging systems, engine components, etc., can solve the problems of uneven swirl strength in the circumferential direction and damage to the symmetry of swirl strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

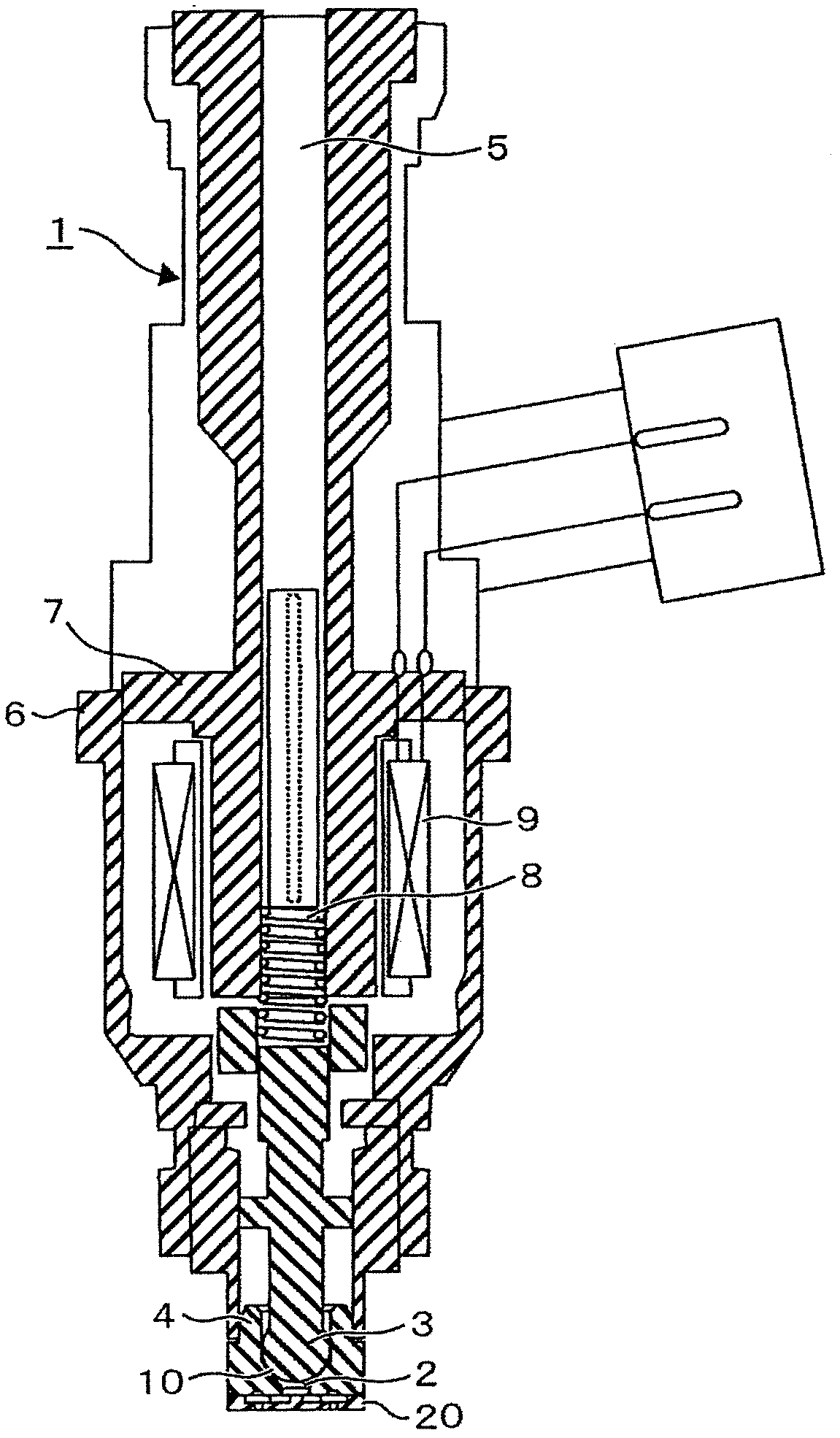

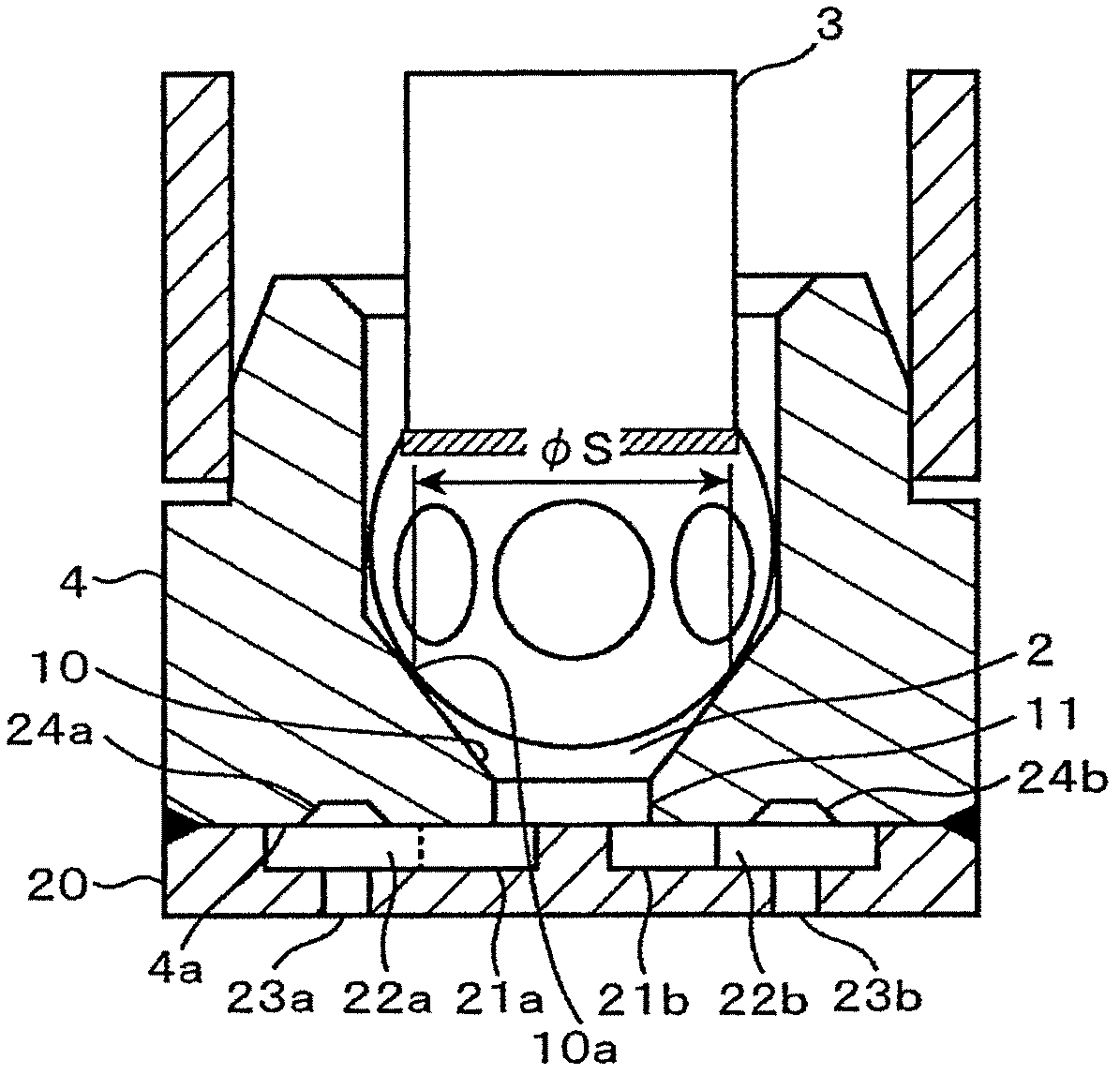

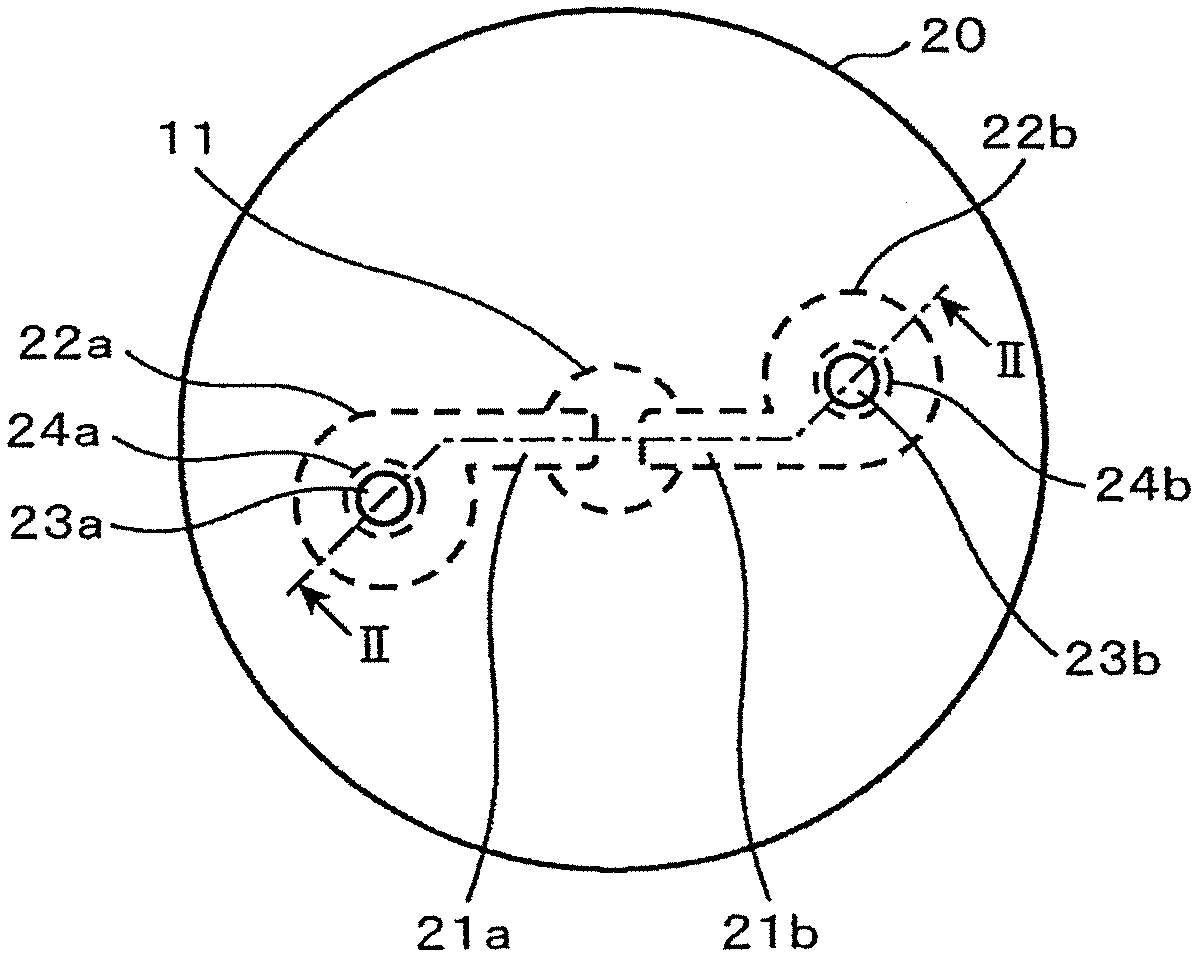

[0040] Below, refer to Figure 1 to Figure 6 , the fuel injection valve according to the first embodiment of the present invention will be described in detail.

[0041] figure 1 It is a longitudinal cross-sectional view along the direction of the valve axis of the fuel injection valve according to the first embodiment of the present invention. figure 2 It is an enlarged longitudinal sectional view of the lower end portion of the nozzle body in the fuel injection valve according to the first embodiment. image 3 This is a view of the orifice plate located at the lower end of the nozzle body in the fuel injection valve according to the first embodiment viewed from below. 4 is a diagram for explaining a recess (bumper) according to the first embodiment, and is a diagram for explaining a positional relationship between a swirl chamber and a fuel injection hole. Figure 5 It is a figure for demonstrating the flow state (expressed by the velocity vector) in the swirl chamber con...

Embodiment 2

[0095] Below, refer to Figure 7 , the fuel injection valve according to the second embodiment of the present invention will be described in detail. Figure 7 It is a diagram for explaining the structure of the intermediate plate 30 located at the lower end portion of the nozzle body 4 in the fuel injection valve according to the second embodiment of the present invention.

[0096] The difference from the fuel injection valve according to the first embodiment is that an intermediate plate 30 is sandwiched between the nozzle body 4 and the orifice plate 20 , and a surface 30 a of the intermediate plate 30 facing the orifice plate 20 is provided There are recessed parts (buffer parts) 24a, 24b. The intermediate plate 30 and the orifice plate 20 can be fixed to the nozzle body 4 after alignment, assembly and adjustment in advance. Since the assembly adjustment is performed in advance, the characteristics of the spray shape and injection amount can be measured in the component a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com