Waterproof masking tape and adhesive for same

A technology of masking tape and adhesive, applied in the direction of adhesive, natural rubber adhesive, adhesive type, etc., can solve the problems of affecting the masking effect, easy to have residual glue, poor high temperature resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with embodiment:

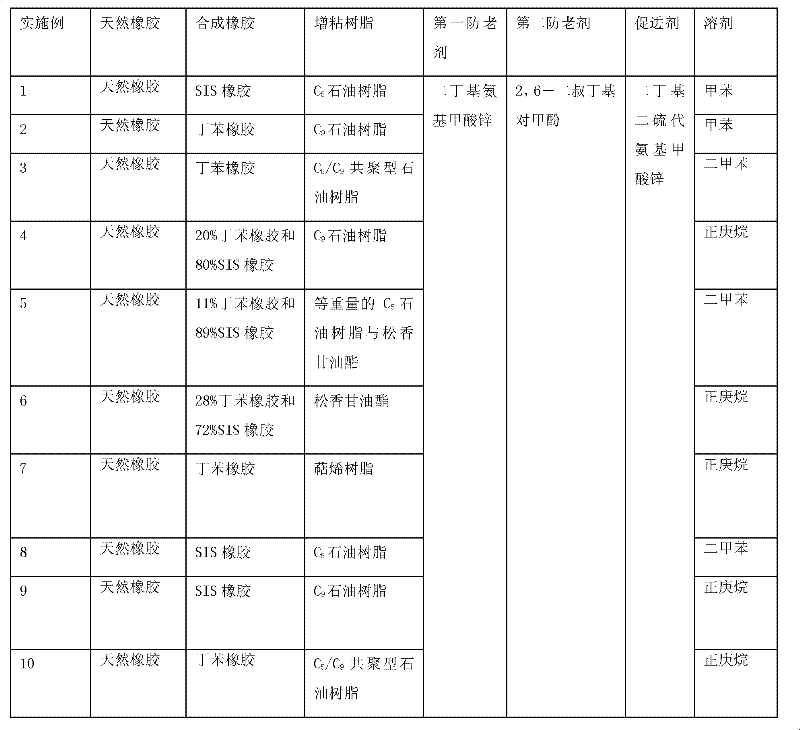

[0024] Formulation and preparation of adhesives for waterproof masking tapes.

[0025] The weight percent composition of every kind of raw material is as follows in each embodiment:

[0026] Example

tackifying resin

Accelerator

Antiaging agent

1

10%

10%

10%

1%

2%

67%

2

30%

20%

30%

3%

5%

12%

3

20%

15%

20%

2%

3.5%

39.5%

4

12%

14%

26%

2.5%

4%

41.5%

5

16%

15%

18%

1.6%

4.3%

45.1%

6

23%

13%

18%

1.7%

2.6%

41.7%

7

12%

14%

26%

1.8%

4.4%

41.8%

8

16%

15%

18%

2.1%

3.3%

45....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com