Hot melt masking tape and production process thereof

A masking tape and production process technology, applied in the direction of adhesives, adhesive types, other rubber adhesives, etc., can solve problems such as insufficient adhesive base force, weak tensile strength, and insufficient cohesive force, and achieve excellent waterproof performance. The effect of excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further elaborated below by way of specific embodiments:

[0025] This embodiment provides a production process for hot-melt masking tape, which specifically includes the following steps:

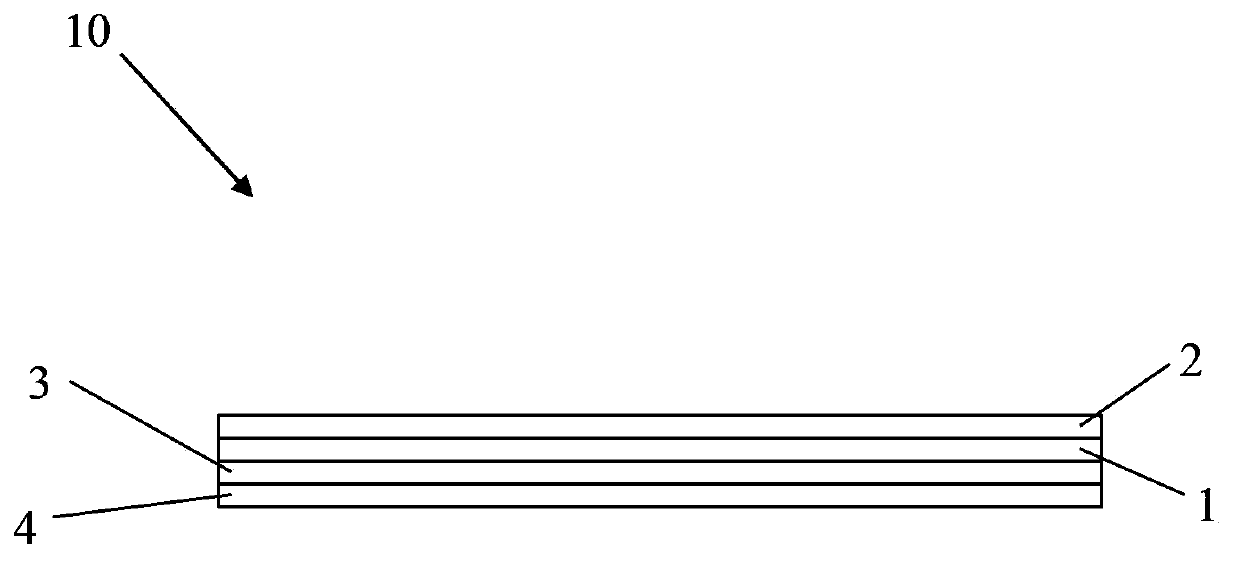

[0026] a. Select masking paper 1, and dip the masking paper 1 in carboxylated styrene-butadiene latex;

[0027] b. Use a mixture of tackifying resin emulsion and modified styrene-butadiene emulsion as a primer to spray one side of the masking paper 1 at room temperature, and perform high-temperature treatment;

[0028] c. Use a mixture of vinegar-acrylic emulsion and silicone as a release agent to coat the other side of the masking paper 1 with silicon, and perform high-temperature treatment;

[0029] d. Use hot melt adhesive to scrape coat the surface of the primer at a temperature of 100-190°C.

[0030] The temperature of the high temperature treatment in the step b is 100-150°C, and the treatment time is 10-40s. The temperature of the high temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com