Manufacturing process for macerative masking tape

A production process and textured paper technology, which is applied to paper, papermaking, paper machines, etc., can solve the problems that the flexibility, strength, and thickness of textured paper cannot be well coordinated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

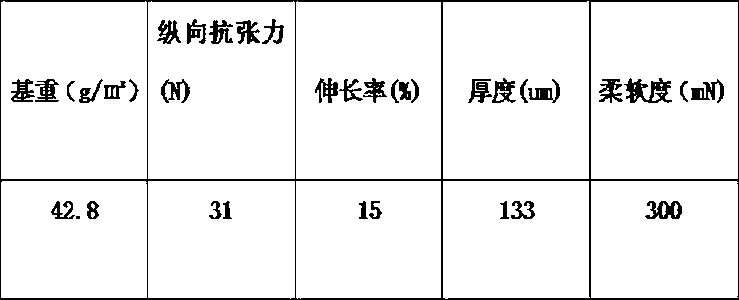

Embodiment 1

[0012] Wood pulp ratio: Beimu 50% + Golden Lion 50%. This ratio is used to decompose the wood pulp through the pulping equipment (hydraulic pulper). The beating degree is 40°SR, the wet weight is 6g, and the beating concentration is 3.5%. The prepared pulp is pumped into the pulping tank for pulping. Add a softener when preparing the pulp, wherein the softener is stearate, the dosage is 3kg / T pulp, and it is added at room temperature. After stirring evenly, add wet strength agent 30kg / T every 30 minutes. When wet strength agent is added, it needs to be filtered, and then the prepared mixed slurry is pumped to the forebay for further dilution, purification, screening, and then through the headbox Spray evenly onto the forming net, remove part of the water by vacuum suction, and then transfer to the press section, wrinkle before the drying cylinder, control the wrinkle dryness to 36%, control the angle between the wrinkling scraper and the cylinder at 35°, The wrinkling speed d...

Embodiment 2

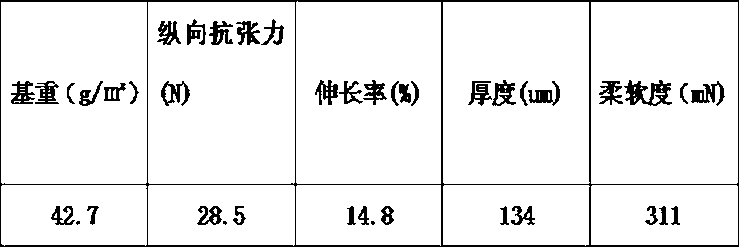

[0017] Wood pulp ratio: Beimu 50% + Silver Star 50%. This ratio is used to decompose the wood pulp through the pulping equipment (hydraulic pulper). The beating degree is 55°SR, the wet weight is 11g, and the beating concentration is 4.8%. The prepared pulp is pumped into the pulping tank for pulping. Add softener when mixing pulp, dosage 8kg / T pulp, add at room temperature. After stirring evenly, add wet strength agent 35kg / T every 45 minutes. When the wet strength agent is added, it needs to be filtered, and then the prepared mixed slurry is pumped to the forebay for further dilution, purification and screening, and then passed through the headbox Spray evenly onto the forming net, remove part of the water by vacuum suction, and then transfer to the press section, wrinkle before the drying cylinder, control the wrinkle dryness to 41%, control the angle between the wrinkling scraper and the cylinder at 30°, The wrinkling speed difference is 11%, and the wrinkling rate and th...

Embodiment 3

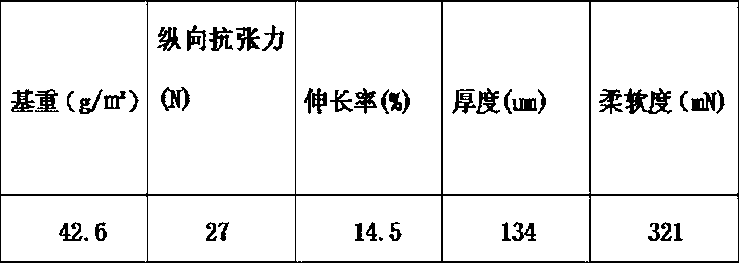

[0022] Ratio of wood pulp: Beimu 50% + Xiongshi 50%, this ratio is decomposed by pulping equipment (hydraulic pulper), the beating degree is 70°SR, the wet weight is 8g, and the beating concentration is 3.6%. The prepared pulp is pumped into the pulping tank for pulping. Add softener when mixing slurry, dosage 5kg / T slurry, add at room temperature. After stirring evenly, add wet strength agent 45kg / T every 60 minutes. When the wet strength agent is added, it needs to be filtered, and then the prepared mixed slurry is pumped to the forebay for further dilution, purification and screening, and then passed through the headbox Spray evenly onto the forming net, remove part of the water by vacuum suction, and then transfer to the press section, wrinkle before the drying cylinder, control the wrinkling dryness to 45%, control the angle between the wrinkling scraper and the cylinder at 25°, The wrinkling speed difference is 20%, and the wrinkling rate and thickness can be controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com