Special sweat-resistant waterproof hot-melt pressure-sensitive adhesive for adhesive bandage and preparation method thereof

A hot-melt pressure-sensitive adhesive, waterproof technology, applied in the field of pressure-sensitive adhesives, can solve the problems of poor waterproofness, inability to effectively block external sewage, waterproofness and air permeability cannot be well unified, etc. Application value and development prospects, the effect of good waterproof and breathable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

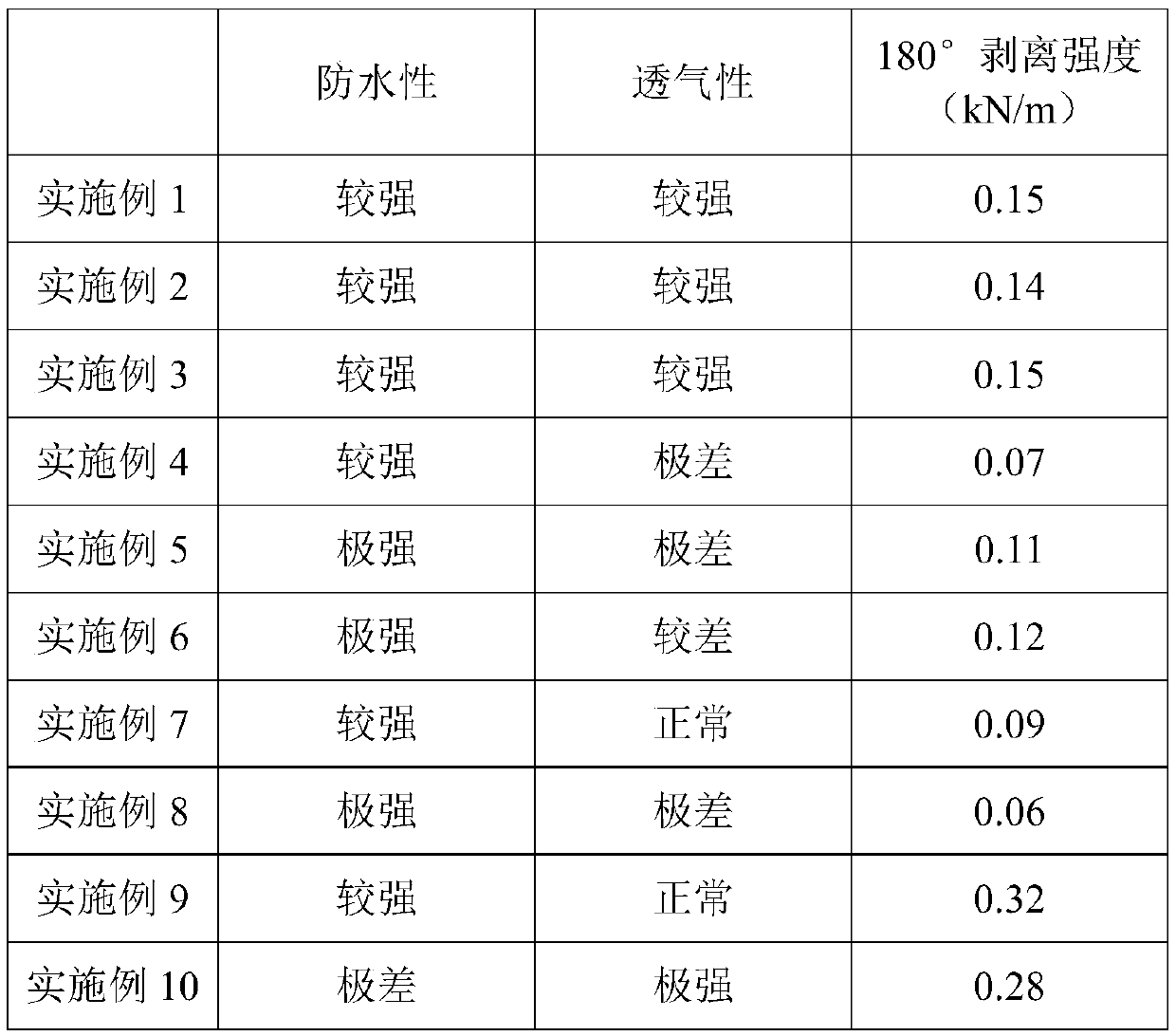

Examples

preparation example Construction

[0057] In a preferred embodiment, the preparation method of the modified petroleum resin comprises the steps of:

[0058] Step a, in parts by mass, add 18-22 parts of petroleum resin and 1-2 parts of plasticizer into the stirring device, and stir at 90-110° C. at a stirring speed of 300-400 rpm for 30-60 minutes to obtain mixture A;

[0059] Step b, adding 1-2 parts of catalyst and 4-6 parts of methyl cinnamaldehyde to the mixture A obtained in step a, stirring at 90-110° C. at a stirring speed of 200-350 rpm for 2-4 hours to obtain mixture B;

[0060] In step c, after washing, filtering and drying the mixture B obtained in step b, the modified petroleum resin is obtained.

[0061] In a more preferred embodiment, the preparation method of the modified petroleum resin comprises the steps of:

[0062] Step a, in parts by mass, add 20 parts of petroleum resin and 1.5 parts of plasticizer into the stirring device, and stir at 100° C. at a stirring speed of 350 rpm for 45 minutes ...

Embodiment 1

[0099] Embodiment 1 of the present invention provides a hot-melt pressure-sensitive adhesive, including the following raw materials in parts by mass: 35 parts of styrene resin, 16 parts of filler, 20 parts of petroleum resin, 6 parts of dispersant, and 2 parts of anti-aging agent.

[0100] The styrene resin is a styrene-isoprene-styrene triblock copolymer; the styrene-isoprene-styrene triblock copolymer is a styrene-isoprene- Isoprene-styrene triblock copolymer.

[0101] The filler is a plastic filler; the plastic filler is polyethylene wax.

[0102] The petroleum resin is a modified petroleum resin; the petroleum resin is a methyl cinnamaldehyde modified petroleum resin.

[0103] The preparation method of described modified petroleum resin comprises the steps:

[0104] Step a, in parts by mass, add 20 parts of petroleum resin and 1.5 parts of plasticizer into the stirring device, and stir at 100° C. at a stirring speed of 350 rpm for 45 minutes to obtain mixture A;

[0105] ...

Embodiment 2

[0113] Embodiment 2 of the present invention provides a hot-melt pressure-sensitive adhesive, including the following raw materials in parts by mass: 30 parts of styrene resin, 14 parts of filler, 18 parts of petroleum resin, 5 parts of dispersant, and 1 part of anti-aging agent.

[0114] The styrene resin is a styrene-isoprene-styrene triblock copolymer; the styrene-isoprene-styrene triblock copolymer is a styrene-isoprene- Isoprene-styrene triblock copolymer.

[0115] The filler is a plastic filler; the plastic filler is polyethylene wax.

[0116] The petroleum resin is a modified petroleum resin; the petroleum resin is a methyl cinnamaldehyde modified petroleum resin.

[0117] The preparation method of described modified petroleum resin is with embodiment 1.

[0118] The petroleum resin is C5 resin; the plasticizer is acetyl tributyl citrate; and the catalyst is aluminum trichloride.

[0119] The dispersant is naphthenic oil; the antioxidant is antioxidant 1010.

[0120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com