Hydrogel and process using hydrogel to produce cooling plaster

A hydrogel and aqueous solution technology, applied in the field of cooling paste production, can solve the problems of easy peeling of the gel part, poor adhesion between the gel and the skin, and difficulty in achieving cooling effects, and achieve moderate adhesion and peeling strength. The effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

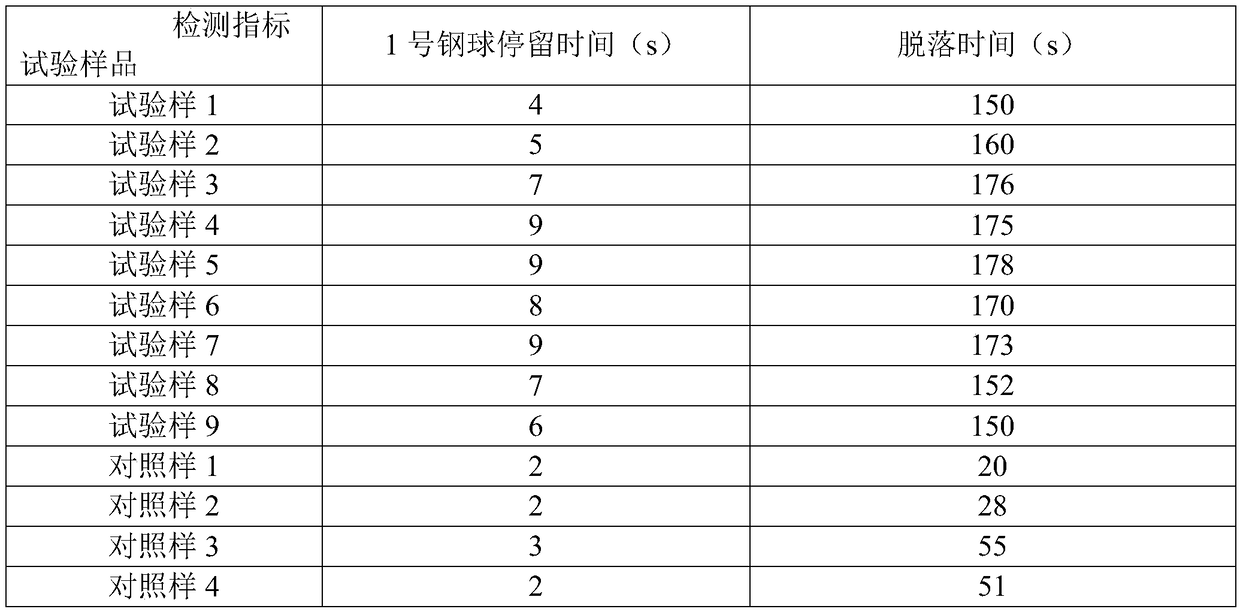

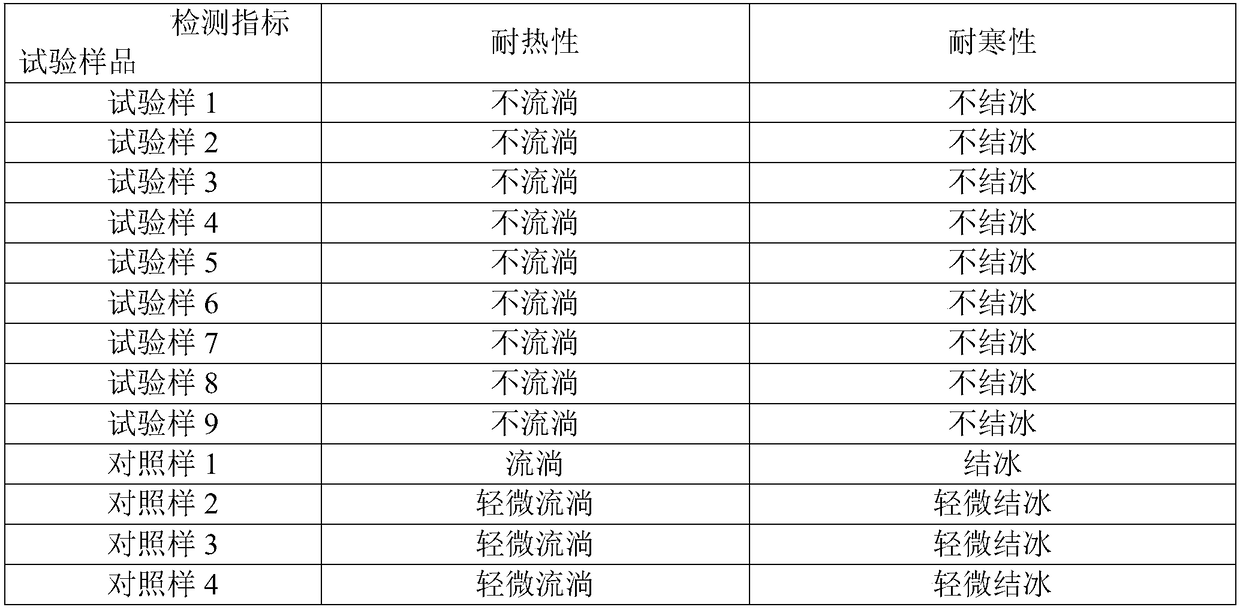

Examples

Embodiment 1

[0074] Embodiment 1: A hydrogel, the components included and their corresponding parts by weight are shown in Table 1, and prepared by the following steps:

[0075] Step 1, fully dissolve the cooling agent in absolute alcohol to form a cool mixture, fully mix glycerin, resin powder, aluminum glycerol, and disodium edetate, and then fully mix with the cool mixture to form an oily mixture; Deionized water, 10wt% tartaric acid aqueous solution, and water-based preservative are fully mixed to form an aqueous mixture;

[0076] In step 2, the thickener is placed in the oily mixture obtained in step 1, fully mixed, and then fully mixed with the aqueous mixture obtained in step 1 to form a blend;

[0077] Step 3: Add polyvinylpyrrolidone to the blend obtained in Step 2 and mix thoroughly to obtain a hydrogel.

[0078] Wherein, the resin powder is HQ841; the thickener is crospovidone; the water-based preservative is DMDMH; the cooling agent is mint and borneol with a ratio of parts by...

Embodiment 2

[0079] Example 2: A hydrogel, the difference from Example 1 is that the components and their corresponding parts by weight are shown in Table 1. In step 1, the nano-microcrystalline cellulose colloid is thoroughly mixed with deionized water, 10 wt % tartaric acid aqueous solution, and a water-based preservative, and the nano-micro-crystalline cellulose colloid contains 0.1 wt % of nano-microcrystalline cellulose.

Embodiment 3-5

[0080] Example 3-5: A hydrogel, the difference from Example 1 is that the components and their corresponding parts by weight are shown in Table 1. In step 1, the nano-microcrystalline cellulose colloid is fully mixed with deionized water, 10wt% tartaric acid aqueous solution, and water-based preservative; the essential oil and 0.1wt% brilliant blue aqueous solution are added to step 3, and fully mixed.

[0081] Components included in Table 1 Embodiment 1-5 and their corresponding parts by weight

[0082]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com