PVC-U drainage pipe fitting as well as preparation method and application thereof

A technology of PVC-U and drainage pipe fittings, which is applied in the field of drainage pipe fittings. It can solve the problems of not easy to scale, easy to scale, and insufficient antibacterial and anti-mildew effects, and achieve a balanced air barrier, anti-aging, and anti-bacterial and anti-mildew capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2 and comparative example 1

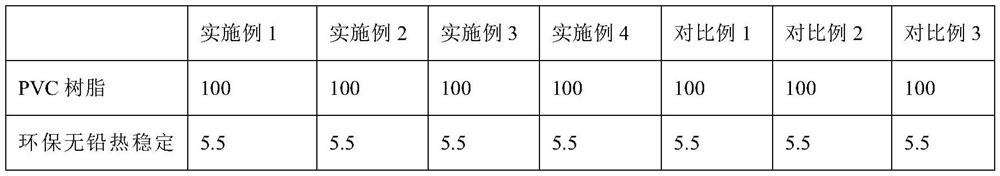

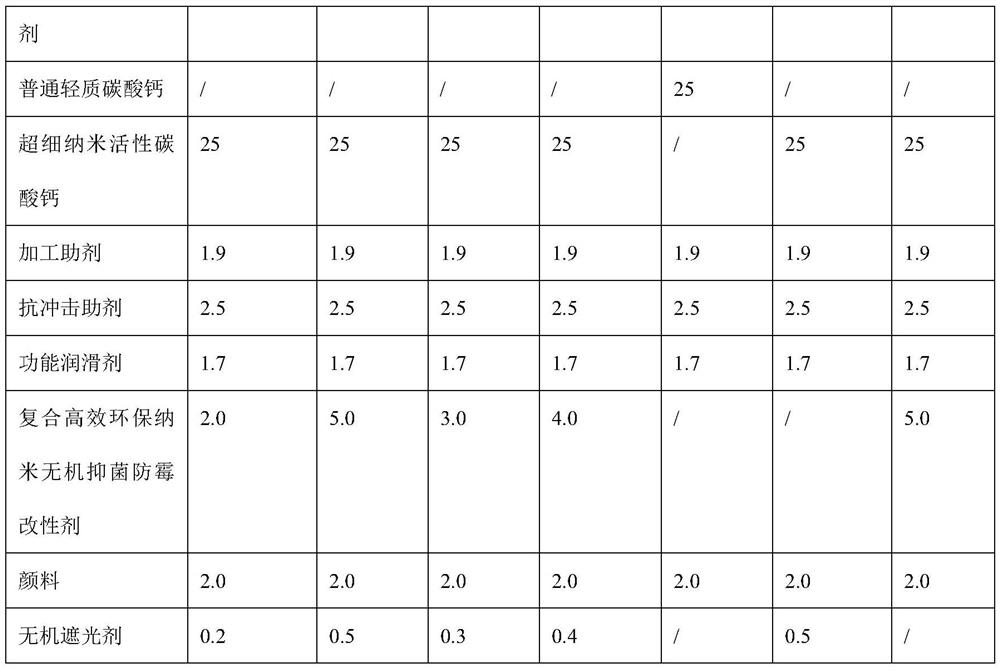

[0068] A PVC-U drainage pipe fitting, including the components calculated in parts by weight as shown in Table 1 below.

[0069] The components and parts by weight of the PVC-U drainage pipe fittings of each embodiment and comparative example in table 1

[0070]

[0071]

[0072] The preparation method of above-mentioned PVC-U drainage pipe fitting, comprises the steps:

[0073] S1. After mixing according to the ingredients of each raw material, add it to a high-speed hot mixer for high-temperature and high-speed kneading and dispersion. When the temperature reaches 115°C, transfer to a cold mixer to stir and cool at a low speed. When the temperature drops below 55°C, discharge it into Hopper, ready for use;

[0074] S2. Add the ready-to-use mixed ingredients in the hopper described in S1 to a twin-screw extruder for plasticization, extrude and granulate, pelletize, cool in a vibrating tower, and pack the pellets; the twin-screw extruder is anisotropic parallel For the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com